Amorphous metal electrodes could bring super-cheap electronics

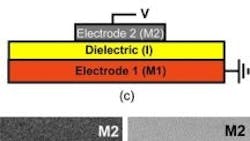

High-performance metal-insulator-metal (MIM) diodes have been devised in an Oregon State University laboratory. The development is thought to be important because such diodes can be alternative less expensive approaches to conventional thin-film transistor technologies as used in such areas as large-area information displays, and ultrahigh speed discrete or antenna-coupled detectors.

MIM diodes have been fabricated before, but have invariably exhibited poor yield and performance, say OSU researchers William Cowell III, Nasir Alimardani, Christopher C. Knutson, John F. Conley Jr, Douglas A. Keszler, Brady J. Gibbons, and John F. Wager. The researchers describe a better fabrication method that can take place at relatively low temperatures (300 C or less) and is relatively inexpensive. Writing in the online journal Advanced, Materials, they say performance problems to date have to a large extent stemmed from the roughness of the surface of the crystalline metal film, which is often larger than the thickness of the MIM insulator. As a result, the electric field across a MIM device will be highly nonuniform, making the control of quantum mechanical tunneling problematic.

The researchers instead use of an amorphous metal contact as a critical component for circumventing the surface roughness and field uniformity roadblocks that have kept MIM electronics from synthesizing high device-current rectification ratios that would make then useful.

The MIM diode basically uses charge carrier tunneling as a current carrying mechanism. To get a uniform electric field across the diode, researchers integrated the atomically smooth-surface of an amorphous metal electrode with high-quality insulators. This combination provides a rich materials and processing palette for development of MIM electronics, enabling new strategies for device design and fabrication, they say.

Relative to crystalline metals, amorphous metals are more electrically resistive by approximately two orders of magnitude. While this resistivity limits their use as interconnects, it is not an impediment to their use as electrodes, researchers say.