Don't let those A/C vibrations go to waste

Most energy harvesting (EH) schemes that try to get energy out of vibrations on a micro scale start with some kind of cantilever contraption that generates electrical energy when it bends. But researchers Soobum Lee of the University of Notre Dame and Byeng D Youn of Seoul National University took a different approach. They simply laminated a thin piezoelectric patch onto a vibrating structure. The EH skin prototype they came up with can generate power up to 3.7 mW, enough for operating wireless sensor units as you might find doing structural health monitoring and/or building automation.

In the EH skin, thin piezoelectric patches are directly attached onto a vibrating shell structure to harvest electric power. The researchers say the direct attachment of thin piezoelectric patches is a well-known method for vibration control and nondestructive structural health monitoring. But nobody until now has used this direct attachment as an energy harvester.

The researchers tried out their idea on an outdoor A/C cooler condensing unit, a type that is widely available around buildings, and which tend to have a lot of harmonic vibration because of imbalance in the motor. They put the EH skin on the top plate of the unit because of its relatively high vibration level.

They measured amplitude components (the average frequency was 59.08 Hz) were used as the input loading condition for a finite-element model. They used the resulting information to figure out the best way to distribute piezoelectric material in the sheet.

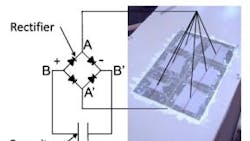

They fabricated the prototype by attaching six PZT patches using conductive epoxy. The conductive epoxy was electrically insulated from the outdoor top plate because the plate was covered with a layer of paint. To prevent short circuits between the top and bottom electrode, they attached transparent tape along the edges of the top PZT surface before curing.

The six patches were connected in parallel so they electrically behaved as one big patch. The top and bottom electrodes were linked to a rectifier and finally a capacitor (100 μF), where the electric charge accumulated.

The researchers got enough power out of the prototype (3.68 mW) to operate, for example, a three-axis accelerometer. They say they may use an advanced wiring technique such as conductive tape or silver pen, to avoid complicated wiring and to keep the design compact in future versions.

View the full paper here: http://iopscience.iop.org/0964-1726/20/5/057001/pdf/0964-1726_20_5_057001.pdf