New Topology Cuts Size, Improves Performance Of PV Inverters

Ideal Power Converters has developed and patented a revolutionary new current-modulation power topology for electronic power converters that will improve both energy and cost efficiency for solar inverters, grid storage, electric vehicle charging infrastructure, ac motor drives, and hybrid-electric vehicles. Its patented topology, or control methodology, depends more heavily on semiconductor switches and advanced software controls than the conventional voltage-source topology, thereby dramatically reducing the amount or weight of magnetic-metal materials.

IPC’s flagship product is a 30kW PV inverter that delivers 480 Vac 3-phase power and supports grounded PV arrays without an internal or external transformer. It weighs only 94lbs, compared to the 1,200lbs for conventional 30 kW 480 Vac PV inverters which work with grounded arrays. This inverter conforms to UL1741 and achieved a CEC-weighted efficiency of 96.5 percent. This efficiency rating is superior to any other CEC-listed PV inverter under 100kW for grounded arrays, the de facto standard in the United States.

This inverter is used for large commercial rooftop arrays and solar carports, where physical space restrictions can add significantly to installation costs. Use of a lightweight inverter can save installers $0.15-$0.20/W in Texas and over $0.30/W in Hawaii, nearly as much as the inverter cost.

Today, the IPC has installations at the University of Texas at San Antonio and Austin, using twelve of its 30 kW inverters. These systems convert +/-450 V from solar arrays into three-phase ac at 480 V that feeds into the power grid. The PV inverter is based on its Universal Power Converter Platform™, which allows the same hadware design with new application firmware to address other markets, including battery converters for grid storage and bi-directional EV fast chargers. Each 30 kW solar inverter weighs just 94 lbs., compared with conventional solar inverters with traditional magnetics that weigh 1,200 lbs. or more. Table 1 lists the inverter’s specifications.

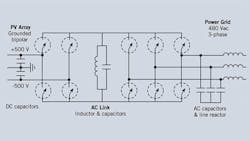

To appreciate the improvements of the new inverter topology, we must first review the older generation PV topologies shown in Fig. 1:

- Boost DC-DC converter that provides a DC link for the inverter.

- DC-DC converter that incorporates an isolation transformer.

- DC-DC converter that transforms the power from the PV array to a low voltage ac that is stepped up using a power transformer.

- Voltage source inverter where the input DC voltage is always higher than the peak-to-peak grid voltage, difficult to realize in PV arrays.

New Topology

IPC’s PV topology (Fig. 2) uses 10 bi-directional switches to conduct or block in either direction. Conventional power semiconductor IGBT components cannot provide this capability, so IPC constructs bi-directional switches from four discrete components: two silicon IGBTs and two silicon diodes. IPC products will migrate to new bi-directional silicon IGBTs (BD-IGBTs) that are being developed with the support of a DOE ARPA-E grant. When these BD-IGBTs are available, it will more than double the power density, while also cutting the cost per watt manufacturing costs and efficiency losses in half.

IPC’s topology uses 100% indirect power transfer, compared with direct power transfer from conventional power converters. All the energy runs through, and is temporarily stored in, a high frequency ac link consisting of an inductor and capacitor. The inverter input and output are never directly connected, so the link provides circuit isolation without the size, weight, and cost of a transformer. Plus, the IPC PV inverter supports standard, grounded PV arrays, compared with European style transformer-less inverters that require the array to be ungrounded.

Fig. 3 compares the circuits for the new BD-IGBTs versus bi-directional switches using commodity IGBTs and diodes. The number of silicon devices and packages are significantly reduced, and the efficiency is significantly improved. Two bidirectional switches are in each leg of the converter output. There is an ac link between the input and output formed by a low-reactive-rating inductor/capacitor pair. In a completely indirect energy transfer operation, the dc input from the PV panels charges the link inductor. This inductive energy then discharges to the output phases.

This patented current-modulation topology offers significant improvements over conventional power electronics topologies in terms of weight, cost, and efficiency while providing the benefits of isolation. The initial 30 kW 480 V PV inverter addresses the needs of the U.S. commercial-scale PV market and will lower PV generation costs.

The 30 kW solar inverter (Fig. 2) is unlike older generation conventional inverters that use an inverter that generates a chopped ac waveform, which is filtered and then transformer coupled to the ac grid, with the transformer preventing ground currents between the grounded array and the grounded neutral of the grid. In contrast, the new design works with grounded arrays but does not use a transformer. It uses a pure ac link formed by an inductor-capacitor pair between the inverter input and output. The link charges from the input(s) and discharges into the output phases via a modulation scheme, resulting in high efficiency, near-unity power factor, and low harmonics. Although transformer-less, the IPC inverter should not be confused with other transformer-less inverters that do not work with grounded arrays.

Most existing commercial PV inverters include a transformer and several sections of power conversion. In non-IPC inverters without transformer isolation (“Transformer-less Inverters”), there is a galvanic connection of grid and PV-generator that results in a large, 120 Hz voltage fluctuation on the array, which may cause a significant leakage current to flow through the capacitance between PV-generator and ground. The magnitude of this capacitance depends on environmental influences. For example, it will be large when the PV-generator is covered with salty fog forming a conductive path to the grounded metallic frame of the PV modules.

Leakage Current

Non-capacitive leakage currents may also be significant, and are also variable with respect to environmental conditions. These non-capacitive leakage currents are checked before the transformer-less inverter starts up, and if the leakage resistance is less than about 200 kΩ, the TL inverter will not start. This may be a very difficult level of array isolation to achieve under all conditions. The IPC inverter also checks for ground leakage resistance on both hot and neutral lines before startup, but in contrast to TL Inverters merely issues a warning over the data interface, and continues operation, thereby avoiding numerous nuisance outages. The IPC inverter is able to do this due to its ability to operate with grounded arrays, but it floats the array during this ground leakage test. The warning issued by the IPC inverter on detecting neutral line faults allows the system operator to fix such faults before they lead to double ground faults which have been known to result in PV array fires.

Operation of the new inverter revolves around its operating modes shown in Fig. 4. In modes two, four, and six, all switches are off and the ac link resonates partially. Then, output switches corresponding to the selected phase pair turn on at zero voltage as they become forward-biased by the rising link voltage. The link then discharges to the output until specific system-generated references are met. Fig. 5 shows the link voltage and current, output current, and dc current show operation in modes seven through ten is identical to that in modes one to five except that the link current is in the reverse direction.

It is possible to realize a link frequency of at least 5 kHz with the semiconductor power switches available today. In the 30 kW inverters installed at the University of Texas, the link frequency is 7 kHz at full power. It goes up to 20 kHz as power drops to zero. The power cycle frequency is twice this, or 14 kHz at full power, because there are two power transfers per link cycle.

All switches in this inverter turn on at zero voltage. Turn-off losses are low because there is a capacitive buffer across each switch. The converter is essentially a PWM current source, although all link current flows are ac with no dc offset.

In operation, input switches are turned on to charge up the link. The link is then allowed to resonate partially, which lets it swing to the voltage of the output phase to which it will discharge. The link nominally discharges to two output phase pairs. The sequence and the pairs are calculated so as to minimize the partial resonance times while meeting the desired harmonic levels. Converter operation involves six operating modes.

Mode 1: Depending on the polarity of the link current, S1i and S2i or S3i and S4i turn on charge the link. In Fig. 4, switches S1i and S2i are turned on. The link current rises to the amount needed to extract maximum power from the PV panel.

Mode 2: At the end of Mode 1, all the switches are turned off and the converter enters its second mode. Here, the link resonates partially until its voltage swings to the first output phase pair. The link then discharges into the grid in two different modes to proportionately power the three output phases. The instantaneous sum of the three phases is zero.

Assume that the output filter results in zero phase shift between voltage and current and that link frequency is much greater than the line frequency. Suppose instantaneous phase voltages are Van = 100 V, Vbn = -70 V, Vcn = -30 V and the link charges to 10 A during Mode 1 (for illustration only, not meant to reflect 480 Vac line voltages or 30 kW inverter). The link would then discharge to lines AB and AC to equivalently supply 7 and 3 A, respectively. This makes the output currents in phase with the output voltages, resulting in unity power factor, thus extracting the maximum real power from the PV cells.

The output discharge happens in order of decreasing instantaneous line voltage to minimize the partial resonant periods. In real life, the actual algorithm removes the assumptions made to handle real scenarios.

Mode 3: Previously enabled output switches, corresponding to the selected phase pair, turn on at zero voltage as they become forward-biased by the rising link voltage. The link then discharges to the output until specific system-generated references are met. Again, the references are generated so as to give unity power factor at the output while maintaining strict harmonic levels. In the nearby example, switches S1o and S6o turn on to let the link discharge to phase BC.

Mode 4: Switches turn off to let the link resonate until its voltage equals that of the second output phase pair into which it will discharge.

Mode 5: Switches become forward-biased to let the link discharge to the second phase pair. In our example, switches S4o and S5o are enabled and then turn on to let the link discharge to phase ac.

Mode 6: The link is allowed to partially resonate back to the input voltage to start the next charging cycle. Then, Modes 7 through 10 are identical to modes 1 through 5, except the link current is in the reverse direction.

At full array voltage and power, the dc input voltage is nominally equal to the ac average output voltages. At reduced PV array voltage and power, as when clouds pass overhead, the converter boosts the array voltage to the required ac output voltage. The inverter can raise or lower the current from the array for MPPT (maximum power point tracking) by controlling the amount of current charge that the link receives from the input.

Simulation results for a 25-kW, 575-V utility grid converter show that the waveforms in various parts of the circuit are shown in Fig. 6. These simulation results looked at the case where the PV array is 400 V and 200 V either side of ground. Simulations also assumed a grounded neutral bipolar array and a grounded neutral three-phase output. Link voltage and currents show the buck capability of the converter. After charging from the input capacitors, the voltage swings to a lower output phase pair to discharge.

Similarly, the converter’s boost capability is also evident. After charging from an input of ±200 V, the link swings to a much higher output voltage to discharge. The converter’s inherent buck-boost capability removes the need for a separate dc-dc stage that directly impacts efficiency. And, the input never directly connects to the output, so there is no need for a transformer.

Although the output voltages and filtered output currents with a ±200 V input show some distortion at points of voltage crossover, these have been eliminated in the production inverter which meets all harmonics limits required by UL 1741.

Related Articles:

DSP Control Improves Inverter Performance and Density

Modified Sine-Wave Inverter Enhanced

Computer-Controlled Micro-Inverters Improve Solar System Performance

IGBTs For Three-Level Inverters Can Meet Energy-Efficient Design Needs