Silicon Carbide Diodes Promise Benefits for Solar Microinverters

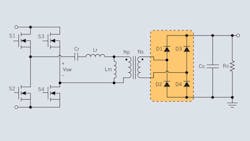

Reliability, efficiency, and system cost are the three key elements in solar inverter design. Vast efforts are being devoted to enhance the performance of solar inverters and so reduce the price per watt harvested from solar panels to gain parity with or surpass fossil fuel energy sources. High performance devices such as Silicon Carbide (SiC) Schottky diodes can boost the performance of solar micro-inverters. This article summarizes a study conducted on a two-stage architecture micro-inverter (Fig. 1) specifically on the dc-dc stage and the application of SiC diodes in the rectification circuit.

LLC resonant converters (Fig. 2) have several desired features such as high efficiency, low EMI and high power density. This makes it is a strong candidate topology for the dc-dc stage in this application. Table 1 shows the typical specification for the dc-dc stage.

LLC Converter Modes of Operation

In order to analyze the performance of SiC diodes, it’s important to understand their operation conditions within the resonant LLC converter. The LLC resonant network can run in three modes, as listed below and shown in Fig. 3.

- Resonant frequency operation, where switching frequency is equal to the resonant frequency of the LLC resonant tank (fs=fr). In this mode, the resonant tank has unity gain and best optimized operation and efficiency, therefore, the converter is designed to operate at this mode at the nominal input voltages.

- Above resonant frequency operation fs>fr, the converter operates in this mode at higher input voltage, where a step down gain or buck operation is required.

-

Below resonant frequency operation, fs

Power Losses in Rectifier Diodes

In general, losses in diodes can be described as in the following two formulas:

Conduction loss = ID.avg * VF

Switching loss = Qrr * VD * fS

Where ID.avg, is the diode average current, VF is the diode forward voltage drop, Qrr is the diode reverse recovery charge, fs is the switching frequency, and VD is the diode blocking voltage.

When evaluating the losses in the rectifier diodes across the input voltage range of a resonant LLC stage (or a solar panel voltage range), we can conclude that the conduction losses remain similar for the same output power since the average diode current is not changed, while the switching losses of the diodes vary across the input voltage range as the switching frequency is modulated. Diode switching losses become significant at higher input voltages, where switching frequency is increasing. In that aspect, SiC diodes are expected to boost efficiency in that mode. Moreover, from an energy harvesting and thermal design perspective, the efficiency at higher input voltages is most important where the solar panel outputs its maximum power and it is desired to limit the peak power dissipation of the inverter.

When selecting diodes for the rectification stage, the two key parameters are the forward voltage drop (Vf) and the reverse recovery charge (Qrr). Since SiC diodes have capacitive charge (Qc) rather than reverse recovery, their switching losses are much lower compared to an ultrafast silicon diode, and will show a performance boost especially in the high switching frequency operation.

Fig. 4a compares the forward voltage drop (Vf) and the reverse recovery time (Trr) of SiC diode against Si ultra-fast diodes. We can conclude that even though SiC diodes have slightly higher forward voltage drop, their switching time and losses are ultra low compared to Si diodes. In other words, the saved switching losses will overcome the insignificant extra conduction losses, therefore total losses will be reduced.

The reverse recovery time (Trr) also indicates switching losses (Fig. 4b) and was used in this comparison only because it’s an available parameter in all compared parts datasheets. It should also be noted that SiC diode has a time constant (Tc), different from Trr for the Si diodes. SiC diodes have no reverse recovery time Trr due to absence of minority carrier injection.

Silicon Carbide Schottky diodes have these benefits:

- Low switching losses due to nearly no reverse recovery charge or stored charge.

- Switching behavior independent on forward current, switching speed and temperature.

Fig. 5 compares SiC Schottky diodes to benchmark Si diodes, Si pin double diodes (2*300V serial in one package) give better reverse current than ultrafast Si pin benchmark diodes, but have much higher forward voltage drop. The capacitive charge Qc and the switching power losses of SiC Schottky diodes are not only ultra low compared to Silicon diodes, but also independent on di/dt, current level, and temperature; where Si diodes have strong dependency on these conditions. Fig. 6 compares SiC and Si diodes in regard to the charge dependency on the forward current and di/dt conditions. A dependence of Qc on these parameters cannot be seen at the same scale as with a benchmark Si diode, this is due to the capacitance-like behavior of SiC devices in reverse direction.

Experimental Results

The performance of the SiC diode was experimentally benchmarked against other silicon ultra-fast diodes at different operating modes of the LLC converter. The experimental prototype has the specification listed in Table 1. Fig. 7 shows the operation at nominal input voltage, where the LLC network has a unity gain and the switching frequency is equal to the resonant frequency, here switching losses are increased compare to the previous mode, in that mode SiC diodes show higher performance than Si ultra-fast diodes, especially at lighter loads.

Fig. 8 shows the operation at high input voltage, where the LLC network has a step down gain and the switching frequency is increased to the higher range; here switching losses are more significant, in that mode SiC diodes clearly show a better performance compared to the Si ultra-fast diodes, at all load conditions.

In conclusion, SiC diodes show higher performance at higher switching frequency operations, due to their ultra low capacitive charge and its associated switching loss and time compared to Si diodes.

References:

- Scarpa, V. ; Kirchner, U. ; Gerlach, R. ; Kern, R. . “New SiC Thin-Wafer Technology paving the way of Schottky diodes with improved performance and reliability”. Proceedings of PCIM Europe 2012.

- Infineon Technologies application note: “Resonant LLC Converter Operation and Design”. September 2012.

- Infineon Technologies application note: “Design Guide for LLC Converter with ICE2HS01G”. July 2011.

- http://www.infineon.com/SiC.

Related Articles:

SiC "Super" Junction Transistors Offer Breakthrough High Temp Performance

SiC: A Rugged Power Semiconductor Compound to Be Reckoned With