Are We Focused On The Wrong Reference Parameters?

The key to optimizing the performance of any circuit begins with determination of the major performance criteria or “figures of merit” (“FOM”). Without a clear understanding of these key device parameters, circuit performance could be compromised. Figure of merit can vary depending on the circuit and application. Most engineers would likely consider the figures of merit (FOM) for a precision voltage reference to be:

- DC initial accuracy

- Temperature coefficient

- Thermal hysteresis

- Output noise

- Reverse current or headroom

- Output impedance

While these are arguably key characteristics, they may not be the most important and the performance in your circuit may often fall far short from the datasheet specifications.

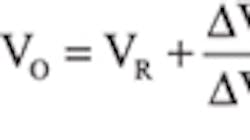

A prerequisite to defining the mathematics of the reference is the understanding that there are different types of references. Specifically, there are series references and shunt references, as well as some that can be operated as either series or shunt devices. References are also either based on bandgap or buried zener elements. Independent of these differences, designers need to be aware of many of the performance characteristics. Then, the output voltage is the sum of the DC terms as shown in:

Where:

VR = Rated reference voltage

VO = Reference voltage output

IO = Reference current in mA

RO = Reference DC output resistance in ohms

T = Temperature in C

VHYST = Hysteresis effect

The resulting reference voltage output includes the initial accuracy of the reference, the temperature coefficient, sensitivity to input voltage or bias current (depending on the reference topology, aging and thermal hysteresis). While this might seem like a complete list, there are many more contributions to the output voltage.

- Thermocouple effects

- Antenna effects

- Impacts of additional buffer amplifiers which are often used with ADC circuits

- Control loop stability

- Dynamic or AC load current variations

- Dynamic or AC input voltage ripple

- Capacitance loading of the reference

Thermocouple effects have been well documented[1] and can result in small changes in the output voltage, as well as independent noise contributions. Other sources of noise include antenna effects, such as from a switching regulator, which couples external noise into the reference output via long or poorly shielded traces. If we assume that the design carefully matches materials and eliminates thermal wind effects, as well as keeping traces short and shielded between ground planes then the thermocouple and thermal wind effects can be neglected along with the antenna effects.

The manufacturer generally provides measurements for the DC, temperature and noise characteristics of their devices. This leaves the dynamic and AC performance, which along with the internal control loop stability contribute to the output voltage variations. (See Table 1)

Several application notes are available that detail measuring voltage references including the measurement of reference output impedance, PSRR and noise[1].

A measurements of the output impedance of a REF03 voltage reference, is described in Fig 2 with the results shown in Fig 3. The measurement shows that while at low frequencies the reference output impedance is resistive, at higher frequencies, the output impedance appears inductive. The addition of a 0.1µF ceramic capacitor destabilizes the reference as can be seen from the 12.3 degree phase margin.

Fig. 4 is the test setup for measurement of PSRR (power supply rejection ratio). The PSRR measurement can also be used to extract non-invasive phase margin. The result of this measurement, shown in Fig. 5 indicates a phase margin of 10.2 Deg, which is close to the measurement obtained from the output impedance. The PSRR result is likely slightly more accurate as the signal resonance is somewhat less distorted. The phase margin is obtained directly from the Bode 100, using the PSRR measurement and the group delay, in much the same way as from the output impedance.

The typical specified DC line regulation from the datasheet is 20ppm; when converted to dB is:

This result is in excellent good agreement with the low frequency measured value seen in Fig. 5. Note that the specification is only provided for DC terms and not as a function of frequency.

Evaluating the impact of the control loop stability on the output noise we can show how input ripple to the reference or small load current variations at the regulator output can easily impact the reference performance. The typical output noise is listed in the manufacturers datasheet as 6µVpp.

The PSRR at 94 kHz, with the recommended 0.1µF, capacitor is obtained from Fig. 5 as 32.345dB and multiplying this by the typical specified 6µVpp noise level results in:

This means that a 250µVpp 94 kHz noise signal at the reference input will result in an output noise signal that is equal to the typical specified reference output noise.

Similarly, the output impedance at 94 kHz is determined to be 135Ω from Fig. 3. Dividing the typical 6µVpp noise level by this output impedance we can determine the level of external load current variation required to equal the specified noise.

This result indicates that a 94 kHz, 44nApp noise current, applied to the reference output, will equal the typical specified noise level.

Fig. 6 shows the step load response with and without the addition of a 0.1uF ceramic output capacitor. The severe ringing in the output response with the 0.1µF capacitor is representative of the very poor phase margin, indicated in both the PSRR and output impedance measurements. This step load figure also shows that the ringing frequency is output current dependent as is the circuit Q. This can be determined since the responses are different at the low current level (150µA) than at the higher current level (425µA).

Comparing the results of the measurement with the specification it becomes clear that the data sheet supplied specification does little in the way of characterizing the AC or transient performance we can expect from the circuit. We can also conclude that using the REF03 with the manufacturer’s recommended 0.1μF output capacitor significantly degrades the AC and transient performance of the part.

In order for engineers to predict the performance of references in real applications, and maybe more importantly, to assist in the selection of a reference, FOMs need to be carefully re-evaluated.

In order to predict the performance of these reference voltage devices is it imperative that the manufacturers include an output impedance specification such as effective output inductance or alternatively Ohms/Hz AND a PSRR specification in dB-MHz. These specifications, in addition to the DC performance specifications, would allow the part’s stability to be assessed, as noted in a recent PET article[2], while also allowing a better assessment of the PSRR.

As an example, it is currently possible for two reference devices to both specify a 90dB PSRR (as voltage stability or as a 120Hz data point), however, the parts may offer very different results at higher frequencies, where the larger concerns are. In the case of the REF03 with a 0.1µF capacitor, the PSRR is only 32dB compared with 93dB at low frequency. This effect could be remedied by specifying PSRR in a similar way to gain bandwidth. The PSRR of 32dB in Fig. 5 with the 0.1μF capacitor at 94kHz is equivalent to a linear attenuation of approximately 40dB. Multiplying this by the 94kHz results in a PSRR specification of 3.76 MHz. Comparing this result to the curve without the capacitor from Fig. 5, the PSRR at 94kHz is 50dB, or a linear attenuation of 316. Multiplying this value by 94kHz results in 29. 7MHz. The degraded stability reduced this FOM by nearly a factor of 8. This recommended FOM also allows us to bound performance at other frequencies. For example, if we want the PSRR at 200kHz, we could divide the 29.7MHz by 200kHz and the result is 148. Converting this to dB results in 43dB PSRR, which is in good agreement with Fig. 5.

These improved FOM’s would also benefit manufacturers, as it helps customers justify the higher cost for a part with real performance improvements. Lastly, they would increase the customer’s chances for a first pass design success rate. The FOM’s also apply to linear voltage regulators, LDOs, and in many cases also to op-amps.

REFERENCES

- “Measuring the Output Impedance of Voltage References and Zener Diodes”, Picotest Blog

- “A Simple Method to Determine ESR Requirements for Stable Regulators”, Steve Sandler, Power Electronics Technology, August 4th 2011

Related Articles

Voltage Reference Fits in 2-mm × 2-mm DFN

About the Author

Steve Sandler

Steve Sandler is the founder and chief engineer of AEi Systems LLC and the president of Picotest. At Picotest he is responsible for signal injector product development, as well as the overall operation of the test equipment company.