An ultracap that mimics a battery

Ultracapacitors come in handy for storing energy that needs to be delivered in short bursts. Problem is, they share the voltage behavior of ordinary capacitors: their voltage drops as they discharge.

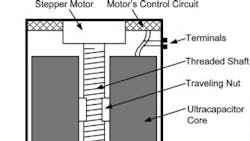

Now a researcher from the University of West Florida claims to have designed an ultracapacitor that maintains a near steady voltage. The novel design is not without its quirks, however: It uses a stepping motor to physically move internal parts as a means of maintaining its output voltage.

Standard capacitors store energy in an electric field created when opposite electrical charges collect on two plates separated by a thin insulating material. In ultracapacitors the surface area of the plates is increased with a coating of porous activated carbon packed with tiny holes and cracks that can capture charged particles. The space between the plates is filled with an electrolyte solution containing positive and negative ions. As charge accumulates on the plates, they attract ions, creating a double-layer of stored energy.

Ezzat Bakhoum, a professor of electrical engineering at the University of West Florida, has designed an ultracapacitor fitted with a step motor that can slowly lift the core of the device out of the electrolyte solution as the stored charged releases. As the electrolyte drains away, the device can hold less charge, thus lowering its capacitance. The voltage of the capacitor is related to the ratio of the stored charge to the capacitance, so the system maintains a steady voltage as charge drains off.

Bakhoum attached a 35-W load to a prototype device and found he could successfully program the voltage to stay within a 4.9 to 4.6-V range. Testing also showed that the constant-voltage mechanism operates with a 99% efficiency or higher. The lifetime of the electromechanical motor is expected to be about the same as the lifetime of the ultracap core, Bakhoum writes.

Future research steps include modifying the design of the constant-voltage ultracapacitor system so it can be installed at any angle. Bakhoum says he may also explore whether the same type of constant-voltage approach is suitable for new, high-energy-density ultracapacitors.

Bakhoum described his work in described in the American Institute of Physics’ Journal of Renewable and Sustainable Energy. The paper, “Constant Voltage Ultracapacitor,” can be found here: http://jrse.aip.org/resource/1/jrsebh/v4/i3/p033116_s1