Networked Automotive Subsystems Becoming the Rule of the Road

The automobile is now becoming an extension of the home. Infotainment systems are becoming default equipment in new cars with connectivity to nearby devices and other cars. Networked equipment in the automotive infrastructure is becoming the future de-facto standard for cars.

Related Articles

- High Speed Bus Transceiver for Automotive Networking

- Bosch predicts evolution of automotive electronics to networked driver assistance

- International Conference and Exhibition on Automotive Network Architecture in Frankfurt on 23 March 2010

- Freescale, Philips collaborate to speed FlexRay product development

Likewise, with driver assistance being the path for automotive safety where traffic accident deaths are eliminated because the car and infrastructure are designed to achieve this goal regardless of the driver’s mistakes or intentions, ADAS will join other passive and active systems as part of the standard car equipment.

These feature-rich infotainment and driver assistance systems will substantially increase the demand for communication bandwidth, while also increasing the complexity of car networks. Because more complex car networks affect reliability and maintainability, the increase in infotainment and driver assistance systems have led to the need for a new networking solution, beyond today´s approach of point-to-point links or ring topologies, which provide no communication between automotive domains.

Ethernet provides the necessary capability for next-generation in-vehicle networking architectures, providing:

· Scalability, a key feature for most automotive OEMs, enables the use of a platform approach for multiple car lines. This scalability is supported through the use of network technology that allows the customization of each vehicle.

· Flexibility also is a key feature as it allows the car OEM to offer several car customizations to the user without any change to the network. The network configuration will adapt itself to the specific set of accessories with which the car is equipped. Car manufacturers will not need to configure the network for each model version.

All major automakers agree on the advantages of segregating the different functional domains within the car. Within this new paradigm, the car will comprise a number of different domains working together and sharing information. Examples of domains are power train, body, transmission, and safety systems.

Within each domain, the type of connectivity used will be based on the functions that need to be performed and the domain requirements. Typical intra-domain networks will be based on FlexRay, MOST, Ethernet, CAN or LIN (see sidebar: Automotive Definitions).

To meet the new requirements of a hierarchical architecture, a broadband network will be needed to communicate with all the domains in a reliable way. Ethernet seems to be the best choice as of today; however, the most appropriate PHY layer for Gigabit-speed is still under discussion. One optical PHY based on Plastic Optical Fiber (POF) will deliver the needed bandwidth of one Gbps, which fulfills all the requirements of current and next-generation systems while at the same time delivering the advantages of lower cost and weight.

The centralized architecture in use today is shown in Fig. 1. In this architecture, a single Central Gateway (CGW) provides CAN connections (solid green, LIN connections (grey), FlexRay connections (dashed green) and MOST connections (dotted green).

In the distributed backbone architecture, vehicle subsystems are grouped into domains that can have a single network technology, like CAN or Ethernet, or a mixture of technologies.

With this new domain-based architecture, the need arises for a backbone that connects all the Domain Control Units (DCU) and switches of each domain with each other. While there are several backbone architectures, the most compelling is the daisy-chain backbone with an optional redundant path (Fig. 2).

As the single backbone connects all the domains, its size should accommodate the data required to be moved between each domain. Future projections show that a one Gbps backbone will be needed to meet the data requirements of all the ADAS and Infotainment systems, along with current existing domains within the car.

The physical layer of the network technology used for the automotive network must meet the unique challenges of the automotive environment, without significantly driving up costs. The final cost of the system not only depends on the performance itself, but on the performance within the automotive environmental conditions, which, in most cases will increase the final cost.

Challenges for automotive networks include:

· Vibration: the network technology must be able to withstand the vibrations that are inherent in the automobile due to continuous movement. Vibrations affect all mechanical parts and are especially damaging to electrical connections, while imposing severe restrictions to cables and connectors.

· Temperature: different temperature ranges are specified for each car domain, depending on the location of the network. The maximum temperature for most automotive domains is 105 °C.

· Weight: the weight of the medium used for the network is very important as it directly impacts fuel consumption/costs not to mention the associated carbon dioxide emissions.

· Cost Predictability: physical layers based on copper are subject to unpredictable pricing as copper prices have significantly increased over the last ten years. The inability to predict costs is a negative factor affecting copper-based solutions.

· Electromagnetic Compatibility (EMC): electromagnetic emissions and susceptibility is a significant challenge for an automotive network. Electrical-based communications, like copper, used for physical layers are especially susceptible to EMI (Electromagnetic Interference).

· Length: the typical length of an automotive network is about five meters, with some networks extending up to 15 meters. Any communications technologies used in an automotive network must be able to cover these lengths with enough signal-to-noise ratio margin. There are also intermediate connections.

POF, a well-known transmission media within the automotive space, now offers Gigabit capabilities that make it the perfect solution for the backbone of future Ethernet automotive networks, as well as for point-to-point links like those required in camera applications. As an optical medium, POF does not have the typical limitations of electrical-based physical layers, such as EMI, weight and cost predictability. Compared with other optical solutions based on silica fibers, POF—which is well known in the automotive market due to the MOST and FlexRay protocols—is much easier to handle and less expensive to install and maintain. Finally, KDPOF technology, which is specified by VDE and ETSI, POF, can overcome the current optoelectronics limitation to reach the one Gbps performance required by the stringent automotive standards.

In meeting the unique challenges of the automotive environment, POF offers several advantages over copper-based solutions and even silica fibers:

· Vibration: POF is an optical technology that does not use electrical contacts, so it avoids electrical noise induced by vibrations. The large core diameter (1 mm) of POF also makes it robust enough to protect against vibration-induced noise.

· Temperature: It is a polymer material that is more sensitive to temperature than copper or silica fibers. However, POF solutions for the most common high temperature ranges in the automotive environment (105 °C) enable the use of POF in all the target car domains. Moreover, while the optical transceiver currently has an upper temperature limit of 95 °C, the newest AVAGO transceiver for Gigabit POF links is aiming for temperatures of up to 105 °C.

· Weight: POF is much lighter than copper, weighing one sixth of a UTP class 5 copper cable. The reduced weight of POF, scaled to the overall communication wiring mesh required within the car, adds up to a substantial weight advantage over copper.

· Cost Predictability: polymer is a material not dependent on the extreme swings of commodity market prices. On the contrary, copper is subject to extreme pricing fluctuations, more than quadrupling in the past decade. In 2002 copper traded for less than USD $1.00 per pound, and in 2012 sold for just under USD $4.00 per pound.

· EMC: System designers prefer optical solutions like POF that are immune to electrical noise, which translates into an increased noise margin and simpler system solutions. System testing is simplified with the benefits of lower development costs and shorter time to market.

· Length: gigabit POF technology is able to extend the typical automotive 15 meter target up to 40 meters and a combination of in-line connectors, thus opening new applications for buses and trucks at the same time keeping the stringent noise margins of the shorter car targets.

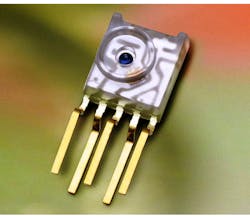

Connectors for POF are quite different from their copper-based counterparts that use solder, crimped connections, or special pins. In addition, supporting devices are different, such as this 1GBPS transceiver for use with optical fiber systems (Fig. 3). An optical fiber connector terminates the end of an optical fiber, and enables quick connection and disconnection. The connectors mechanically couple and align the cores of fibers so light can pass from the cable to the connector. Better connectors lose very little light due to reflection or misalignment of the fibers. Most optical fiber connectors are spring-loaded, so the fiber faces are pressed together when the connectors are mated. The resulting plastic-to-plastic contact eliminates signal losses that would be caused by an air gap between the joined fibers. Typical connectors are rated for 500–1,000 mating cycles. The main differences among types of connectors are dimensions and methods of mechanical coupling. Fig. 4 shows an optical fiber cable and connector.

Good connectors exhibit:

· Low insertion loss

· High return loss (low amounts of reflection at the interface)

· Ease of installation

· Low cost

· Reliability

· Low environmental sensitivity

· Ease of use

For more information and feedback, contact Thomas Lichtenegger at t[email protected].

Sidebar: Automotive Definitions

Advanced Driver Assistance Systems, or ADAS, aid safe driving. Examples are:

· In-vehicle navigation system with typically GPS and TMC for providing up-to-date traffic information.

· Adaptive cruise control (ACC)

· Lane departure warning system

· Collision avoidance system (Pre-crash system)

· Intelligent speed adaptation or intelligent speed advice (ISA)

· Pedestrian protection system

· Vehicular communication systems

· Electric vehicle warning sounds used in hybrids and plug-in electric vehicles

· Satellite navigation systems

CAN bus (for controller area network) is a vehicle bus standard designed to allow microcontrollers and devices to communicate with each other within a vehicle without a host computer. CAN bus is a message-based protocol, designed specifically for automotive applications but now also used in other areas such as aerospace, maritime, industrial automation and medical equipment.

FlexRay is an automotive network communications protocol developed by the FlexRay Consortium to govern on-board automotive computing. It is designed to be faster and more reliable than CAN and TTP, but it is also more expensive. The FlexRay consortium disbanded in 2009. The FlexRay standard is now a set of ISO standards ISO 17458-1 to 17458-5 .

BroadR-Reach® technology is compatible with upper layer 2 of Ethernet devices and can be used in automotive connectivity applications. BroadR-Reach® technology allows multiple in-vehicle systems to simultaneously access information over unshielded single twisted pair cable. Benefits for automotive manufacturers integrating the BroadR-Reach® Ethernet standard include reduced connectivity costs and cabling weight, according to Broadcom Corporation, inventor of the proprietary BroadR-Reach® technology.

LIN (Local Interconnect Network) is a serial network protocol used for communication between components in vehicles. The need for a cheap serial network arose as the technologies and the facilities implemented in the car grew, while the CAN bus was too expensive to implement for every component in the car. European car manufacturers started using different serial communication topologies, which led to compatibility problems.