UHV SiC Devices Geared Toward Mission-Critical Energy Infrastructure Apps

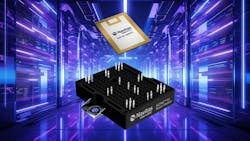

Navitas Semiconductor’s latest 3,300- and 2,300-V ultra-high-voltage (UHV) silicon-carbide (SiC) devices are available in power module, discrete, and known-good-die (KGD) formats. They target applications that require high reliability, high performance, and enhanced avalanche resistance, such as energy storage, renewable power, and megawatt-scale fast-charging.

The devices’ structures are based on Navitas' trench-assisted planar (TAP) architecture, which implements a multi-step e-field management profile to significantly reduce voltage stress and improve voltage-blocking capabilities when compared with trench and traditional planar SiC MOSFETs.

The company’s TAP technology also features an optimal source contact for superior cell-pitch density and enhanced current-spreading. It results in improved switching figures of merit and lower on-resistance at elevated temperatures.

All new UHV products are AEC-Plus certified, a new reliability qualification benchmark that exceeds existing AEC-Q101 and JEDEC product qualification standards. Features include:

- Dynamic reverse bias (DRB) and dynamic gate switching (DGS)

- Over 3X longer duration for static high-temperature, high-voltage tests (HTRB, HTGB, HTGB-R)

- HV-THB qualification for power modules and HV-H3TRB qualification for discretes and KGD

- Longer power cycling and temperature cycling

For applications that demand high power density and high reliability, Navitas offers its devices as integrated modules, configured in half- and full-bridge circuit configurations within a robust SiCPAK G+ power-module package. The packaging also includes an aluminum-nitride direct-bond-copper (AlN DBC) substrate for superior heat dissipation and high-current press-fit pins.

The packages’ proprietary epoxy formulation has been proven to deliver a >60% improvement in power cycling lifetime and a >10X improvement in thermal shock reliability.

Discrete SiC MOSFETs are available in the industry-standard TO-247 and TO-263-7 packages. Products offered as KGD undergo additional comprehensive room and hot temperature testing on singulated die (post-dicing) and a six-side optical inspection. For additional information, check out:

A white paper on the TAP technology is available for free download as well.

Next in This Edition of PowerBites

More PowerBites

About the Author

Lee Goldberg

Contributing Editor

Lee Goldberg is a self-identified “Recovering Engineer,” Maker/Hacker, Green-Tech Maven, Aviator, Gadfly, and Geek Dad. He spent the first 18 years of his career helping design microprocessors, embedded systems, renewable energy applications, and the occasional interplanetary spacecraft. After trading his ‘scope and soldering iron for a keyboard and a second career as a tech journalist, he’s spent the next two decades at several print and online engineering publications.

Lee’s current focus is power electronics, especially the technologies involved with energy efficiency, energy management, and renewable energy. This dovetails with his coverage of sustainable technologies and various environmental and social issues within the engineering community that he began in 1996. Lee also covers 3D printers, open-source hardware, and other Maker/Hacker technologies.

Lee holds a BSEE in Electrical Engineering from Thomas Edison College, and participated in a colloquium on technology, society, and the environment at Goddard College’s Institute for Social Ecology. His book, “Green Electronics/Green Bottom Line - A Commonsense Guide To Environmentally Responsible Engineering and Management,” was published by Newnes Press.

Lee, his wife Catherine, and his daughter Anwyn currently reside in the outskirts of Princeton N.J., where they masquerade as a typical suburban family.

Lee also writes the regular PowerBites series.