Eliminating DC-DC Converter Switching Noise

A common dc-dc converter problem is generating a regulated voltage when the input voltage can be above, below, or equal to the output—that is, the converter must perform both step-up and step-down functions. This scenario is typical when powering vehicle electronics from a nominal 12-V battery, which can vary from engine cold crank (down to 3 V) and load dump (up to 100 V), or a reverse battery voltage from operator error. Several dc-dc converter topologies can perform both step-up and step-down operations, from SEPIC to 4-switch topologies, but none of these pass the input voltage directly to the output without actively switching.

An alternative approach is to utilize a controller that passes the input directly to the output when the input voltage is within a specific window. This eliminates EMI and switching losses while maximizing efficiency (up to 99.99%). For example, the LT8210 is a synchronous buck-boost controller that can operate in a “Pass-Thru” mode, allowing the user to set a programmable window for which the input will be passed directly to the output. Because the input voltage can be passed directly to the output without actively switching the FETs, this results in ultra-low IQ operation and the elimination of switching noise.

For a controller that operates over a wide input voltage range, such 2.8 to 100 V, it enables regulation from the minimum input voltage during cold crank to the peak amplitude of an unsuppressed load dump. Pass-Thru mode is just one operating mode, and controllers can still operate as a conventional buck-boost controller with pin-selectable continuous conduction mode (CCM), pulse skipping, or burst-mode operation.

Pass-Thru Operating Mode

Figure 1 shows a simplified schematic of a circuit configured for Pass-Thru operation; the output is regulated to be between 8 and 16 V. In this example, the top and bottom voltages of the Pass-Thru window are set by the FB2 and FB1 resistor dividers, respectively.

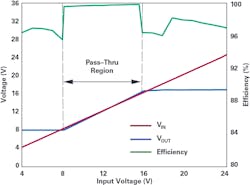

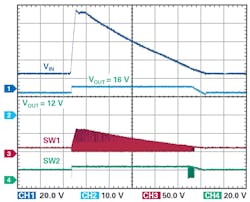

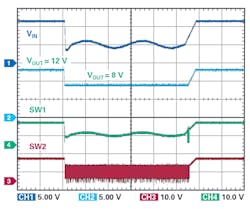

Figure 2 shows the input/output transfer characteristic of this circuit. When the input voltage is above the Pass-Thru window, the controller steps it down to a regulated 16-V output (Fig. 3). If the input voltage drops below the window, the controller boosts to maintain the output at 8 V (Fig. 4).

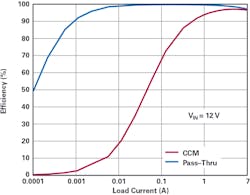

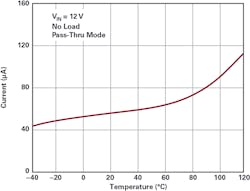

When the input voltage is within the Pass-Thru window, the top switches—A and D—turn on continuously, allowing the output to track the input and the part to enter a low-power state with typical quiescent currents on the VIN and VINP pins of 4 µA and 18 µA, respectively. In this non-switching state, there are neither EMI nor switching losses, making efficiencies greater than 99.9% achievable (Fig. 5).

Automotive batteries and similar wide-voltage-range power sources are a complex problem for dc-dc converter designers, requiring protection features and buck and boost conversion at high efficiency. A synchronous buck-boost controller with Pass-Thru capabilities eliminates complexity by combining protection features with a wide-input-range buck-boost converter. Pass-Thru mode eliminates switching losses and noise while achieving ultra-low quiescent current (Fig. 6). In Pass-Thru mode, the output voltage isn’t regulated in the conventional sense, but is instead bounded by a programmable voltage window.

David Megaw is a Senior Design Engineer and Bruce Haug is Product Marketing Manager at Analog Devices Inc.