Carbon-Nanotube “Forest” Yields Flexible Supercapacitors

Supercapacitors are increasingly useful elements of the energy-storage and power-delivery scenario, often used for harvesting and storage in conjunction with secondary (rechargeable) batteries. However, as with many electronic components, they’re generally housed in rigid enclosures that limit their applicability to flexible and stretchable electronics. These include wearable devices, epidermal and implantable electronics, and biomedical systems that must tolerate large deformations as well as conform to complex surface shapes.

However, that limitation may soon change due a collaboration between researchers at Duke University and Michigan State University (MSU), who have engineered a unique supercapacitor that remains fully functional even when stretched to eight times its original size. Further, it doesn’t exhibit any wear and tear from being stretched repeatedly and loses only a few percentage points of energy performance after 10,000 cycles of charging and discharging.

The robust and stretchable electrode is based on a crumpled gold (Au)-coated carbon-nanotube mixture dubbed an “Au-CNT forest.” To create these stretchable supercapacitors, Jeff Glass, professor of electrical and computer engineering at Duke, and his research team first grow a carbon-nanotube forest—a patch of millions of nanotubes just 15 nm in diameter and 20-30 µm tall—on top of a silicon wafer (Fig. 1).

After that, the researchers then coat a thin layer of gold nanofilm on top of the carbon-nanotube forest. The gold layer drops the resistance of the device an order of magnitude below previous versions, which allows the device to charge and discharge much more quickly.

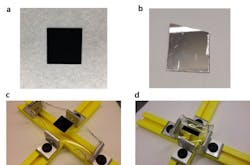

The next step of the process is done by Changyong Cao, assistant professor of packaging, mechanical engineering and electrical and computer engineering at MSU, who transfers the Au-CNT forest to a pre-stretched elastomer substrate with the base gold-side-down (Fig. 2). The gel-filled electrode is subsequently relaxed to allow the pre-strain to release, causing it to shrink to a quarter of its original size. This process crumples up the thin layer of gold and smashes together the “trees” in the carbon-nanotube forest. “The crumpling greatly increases the amount of surface area available in a small amount of space, which increases the amount of charge it can hold,” explained Glass.

The super-dense forest is then filled with a gel electrolyte that can trap electrons on the surface of the nanotubes. When two of these final electrodes are sandwiched close together, an applied voltage loads one side with electrons while the other is drained, creating a charged super-stretchable supercapacitor.

Of course, a stretchable supercapacitor is just one element in a fully stretchable system. “We still have some work to do for building a complete stretchable electronics system,” said Cao. “The supercapacitor demonstrated in this paper doesn’t go as far as we want it to yet. But with this foundation of a robust stretchable supercapacitor, we will be able to integrate it into a system that consists of stretchable wires, sensors, and detectors to create entirely stretchable devices.”

Experimental measurements show that the resistance of the Au-CNT forest electrode is about one order magnitude lower than that of a pure, non-Au CNT forest electrode and is superior to available alternatives (Fig. 3). The crumpled CNT-forest electrodes demonstrated good electrochemical performance and stability under either uniaxial strain up to 300% or biaxial strains of 300% × 300% for thousands of stretching/relaxing cycles.

The resulting supercapacitors can support stretchability of 800% and have a specific capacitance of 5 mF/cm2 at current density of 40 mA/cm2. Furthermore, impregnated metal-oxide nanoparticles can be added to the crumpled CNT-forest electrodes to improve the specific capacitance and energy density of the supercapacitors.

Details of the work are in their paper “Robust and High-Performance Electrodes Via Crumpled Au-CNT Forests for Stretchable Supercapacitors” pre-published in Elsevier’s Cell Press. Although it’s behind a paywall, an unlocked copy is here (you have to scroll down), while substantial additional supporting material is available here.

![1. Fabrication of crumpled-CNT forest electrodes: (a) Schematic fabrication process flow for stretchable supercapacitor electrodes from PECVD-grown multiwall CNT forest, including growth of CNT forest on silicon wafer covered with 5 nm Fe catalyst (I); pretreatment of the samples under 490°C in air for 3 min, and then stamping the CNTs topside-down onto a uniaxially or biaxially prestretched elastomer substrate (II); peeling off the wafer from the target substrate (III); relaxation of the prestrain in the substrate along the first direction (IV); and relaxation of the prestrain in its second orthogonal direction (V). (b) SEM image of CNT-forest grown on a silicon wafer by PECVD for five minutes. The average height of the CNTs is around 20 μm. (c) SEM image of the parallel ridge pattern formed by the CNT-forest on an elastomer substrate after relaxation in one direction. (d) SEM image of the crumpled pattern formed by the CNT-forest on a fully relaxed elastomer substrate (300% × 300%). [The scale bar in (b) is 10 μm and that in (c) and (d) is 100 μm.] 1. Fabrication of crumpled-CNT forest electrodes: (a) Schematic fabrication process flow for stretchable supercapacitor electrodes from PECVD-grown multiwall CNT forest, including growth of CNT forest on silicon wafer covered with 5 nm Fe catalyst (I); pretreatment of the samples under 490°C in air for 3 min, and then stamping the CNTs topside-down onto a uniaxially or biaxially prestretched elastomer substrate (II); peeling off the wafer from the target substrate (III); relaxation of the prestrain in the substrate along the first direction (IV); and relaxation of the prestrain in its second orthogonal direction (V). (b) SEM image of CNT-forest grown on a silicon wafer by PECVD for five minutes. The average height of the CNTs is around 20 μm. (c) SEM image of the parallel ridge pattern formed by the CNT-forest on an elastomer substrate after relaxation in one direction. (d) SEM image of the crumpled pattern formed by the CNT-forest on a fully relaxed elastomer substrate (300% × 300%). [The scale bar in (b) is 10 μm and that in (c) and (d) is 100 μm.]](https://img.electronicdesign.com/files/base/ebm/electronicdesign/image/2020/08/ED_Interest_flexible_supercap_Fig1.5f3e92b64aec8.png?auto=format,compress&fit=max&q=45?w=250&width=250)

![3. Performance comparison of the stretchable, all-solid-state, crumpled-CNT-forest supercapacitors with other CNT supercapacitors reported in literature. The capacitances of this work are measured by charge-discharge at a rate of 50 mV/s. The other data from literature are the stretchable CNT-fiber wire-shaped supercapacitor [33], buckled SWNT supercapacitor [17], selective-wetting induced multiwall carbon nanotube supercapacitor [27], CNT/ion-gel supercapacitor [35], vertically aligned CNT stretchable supercapacitor on PDMS [36], and aligned CNT-forest stretchable supercapacitor on PDMS [37], which are categorized into four different types as indicated by the colored ellipses for easier comparison. (The numbers in [square brackets] refer to specific papers called out in the references.) 3. Performance comparison of the stretchable, all-solid-state, crumpled-CNT-forest supercapacitors with other CNT supercapacitors reported in literature. The capacitances of this work are measured by charge-discharge at a rate of 50 mV/s. The other data from literature are the stretchable CNT-fiber wire-shaped supercapacitor [33], buckled SWNT supercapacitor [17], selective-wetting induced multiwall carbon nanotube supercapacitor [27], CNT/ion-gel supercapacitor [35], vertically aligned CNT stretchable supercapacitor on PDMS [36], and aligned CNT-forest stretchable supercapacitor on PDMS [37], which are categorized into four different types as indicated by the colored ellipses for easier comparison. (The numbers in [square brackets] refer to specific papers called out in the references.)](https://img.electronicdesign.com/files/base/ebm/electronicdesign/image/2020/08/ED_Interest_flexible_supercap_Fig3.5f3e92f036003.png?auto=format,compress&fit=max&q=45?w=250&width=250)