5 Steps to Improved Power-Supply Design Using Semi-Automation

This article is part of TechXchange: Power Supply Design

Members can download this article in PDF format.

What you'll learn:

- How semi-automated tools speed up the power-supply design process.

- The five main steps to take when building a power-supply architecture.

- How do LTpowerPlanner and LTspice help facilitate the different aspects of the design process?

Designing the correct power source is essential and complex since there’s no one typical application. While total automation of power-supply design has yet to be achieved, a comprehensive range of semi-automated tools are available today. This article details the use of semi-automated design tools through five critical steps of the power-supply design process. These tools can be valuable to both the novice and expert power-supply design engineer.

Power-Supply Design Step 1: Creating the Power-Supply Architecture

Creating a suitable power-supply architecture is a decisive step in power-supply design. This step becomes more complex by increasing the number of needed voltage rails. At this point, the decision is made as to whether and how many intermediate circuit voltages need to be created.

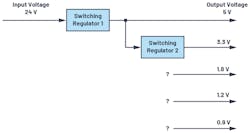

Figure 1 shows a typical block diagram of a power supply. The 24-V supply voltage of an industrial application is shown on the left. This voltage must be converted now into 5 V, 3.3 V, 1.8 V, 1.2 V, and 0.9 V with corresponding currents. What’s the best method for generating the individual voltages?

Selecting a classic step-down switching (buck) converter makes the most sense for converting from 24 V to 5 V. However, how do you generate the other voltages? Does it make sense to generate the 3.3 V from the 5 V already created, or should we convert to 3.3 V directly from 24 V? Answering these questions requires further analysis. Since an important property of a power supply is the conversion efficiency, keeping the efficiency as high as possible is vital when selecting the architecture.

If intermediate voltages, such as 5 V in the example shown in Figure 1, are used to generate additional voltages, the energy utilized for the 3.3 V must already pass through two conversion stages. Each conversion stage has only limited efficiency.

For example, if a conversion efficiency of 90% is assumed for each conversion stage, the energy for 3.3 V, which has already passed through two conversion stages, only has an efficiency of 81% (0.9 × 0.9 = 0.81). Can such rather low efficiency be tolerated in a system or not? It depends on the current required from this 3.3-V rail.

If current of only a few milliamps is needed, the low efficiency might not be a problem at all. For higher currents, though, this lower efficiency might have a greater effect on the overall system efficiency and consequently represent a big disadvantage.

From the considerations just mentioned, however, you can’t draw the general conclusion that it’s always better to convert directly from a higher supply voltage to the lower output voltage in one step. Voltage converters that can handle a higher input voltage are usually more expensive and have a reduced efficiency when a greater difference exists between the input voltage and the output voltage.

In power-supply design, the most efficient way to finding the best architecture is to use an architecture tool. For instance, the LTpowerPlanner from Analog Devices helps accelerate the evaluation of different architectures so that developers can quickly explore different options and their tradeoffs.

Finalizing the SpecificationFinalizing the specification is extremely important in power-supply design. All additional development steps depend on the specification. Frequently, the precise requirements of the power supply are unknown until the rest of the electronic system is completely designed. This usually results in increasing time constraints on power-supply design development. It also often happens that the specification is changed in a later development stage.

For example, if an FPGA requires additional power in its final programming, the voltage for a digital signal processor (DSP) must be reduced to save energy, or the originally intended switching frequency of 1 MHz must be avoided because it’s coupled into the signal path. Such changes can have very serious effects on the architecture and, in particular, on the circuit design of the power supply.

A specification is usually adopted at an early stage. This specification should be designed to be as flexible as possible so that it’s relatively easy to implement any changes. In this effort, selecting versatile integrated circuits is helpful. Working with development tools is particularly valuable because they enable the power supply to be recalculated within a short time. In this way, specification changes can be implemented more easily and, above all, more quickly.

The specification includes the available energy, the input voltage, the maximum input current, and the voltages and currents to be generated. Other considerations include size, financial budget, thermal dissipation, electromagnetic-compatibility (EMC) requirements (including both conducted and radiated behaviors), expected load transients, changes in the supply voltage, and safety.

A tool like LTpowerPlanner provides the necessary functions for creating a power-supply system architecture, allowing for rapid concept development. An input energy source is defined and then individual loads, or electrical consumers, are added. This is followed by adding individual dc-dc converter blocks. These could be switching regulators or low-dropout (LDO) linear regulators. All components can be assigned their own name. An expected conversion efficiency is stored for efficiency calculations.

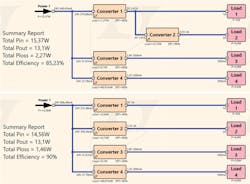

Rapid concept development offers several benefits. First, a simple architecture calculation can identify the configuration of the individual conversion stages most beneficial for overall efficiency. Figure 2 shows two different architectures for the same voltage rails. The architecture at the bottom has an overall efficiency somewhat higher than that of the architecture at the top. This property isn’t evident without a detailed calculation. When using LTpowerPlanner, this difference is immediately revealed.

Another benefit is that rapid prototyping tools provide well-organized documentation. The graphical user interface of LTpowerPlanner, for example, provides a sketch of the architecture, a visual aid that can help broaden the scope of discussions with coworkers as well as document the development effort. Documentation can be stored either as a paper hard copy or a digital file.

Power-Supply Design Step 2: Selecting ICs for Each DC-DC Converter

When designing power supplies today, an integrated circuit is used rather than a discrete circuit with many separate components. A multitude of different switching-regulator ICs and linear regulators are available in the market. All of them are optimized for one specific property. Interestingly, all integrated circuits are different and can be interchanged only in the rarest of cases.

Thus, selecting the integrated circuit becomes a very important step. Once selected, the properties of that circuit are fixed for the rest of the design process. Later, if it turns out that a different IC is better suited, the effort to incorporate a new IC begins anew. This development effort can be very time-consuming, but it can be easily mitigated with the use of design tools.

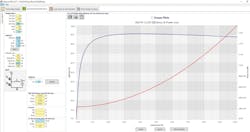

Using a tool is critical for effectively selecting the integrated circuit. The parametric search on analog.com is suitable for this task. Searching for components within LTpowerCAD may be even more productive. Figure 3 shows the search window.

To use the search tool, only a few specifications need to be entered. For example, you may enter the input voltage, output voltage, and required load current. Based on these specifications, the tool generates a list of recommended solutions. Additional criteria can be entered to further narrow down the search. In the “Features” category, for instance, you can select from features such as an enable pin or galvanic isolation to find an appropriate dc-dc converter.

Power-Supply Design Step 3: Circuit Design of Individual DC-DC Converters

Step 3 is the circuit design. The external, passive components need to be selected for the chosen switching-regulator IC. The circuit is optimized in this step. Usually, it requires studying a datasheet thoroughly and performing all of the required calculations. This step in power-supply design can be drastically simplified by design tools, and the results can be further optimized.

One of the main differences between calculation tools and simulators can be seen during this design stage. A calculation tool like LTpowerCAD is able to recommend, in a very short time, the optimized external components based on the specification entered. The conversion efficiency can be optimized, and the transfer function of the control loop is calculated. This facilitates implementing the best control bandwidth and stability.

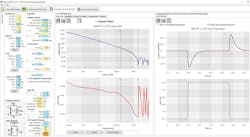

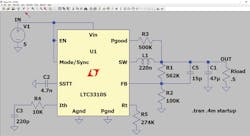

After opening a switching-regulator IC in LTpowerCAD, the main screen displays the typical circuit with all of the necessary external components. Figure 4 shows this screen for the LTC3310S as an example. It’s a step-down switching regulator with an output current of up to 10 A and a switching frequency of up to 5 MHz. The yellow fields on the screen show the calculated or specified values. The user can configure settings using the blue fields.

A calculation tool reliably simulates the behaviors of a real circuit as calculations are based on detailed models of external components, not just ideal values. Specifically, these tools include a large database of integrated-circuit models from several manufacturers. For instance, the equivalent series resistance (ESR) of a capacitor and the core losses of a coil are taken into consideration.

To select external components, click on a blue external component as shown in Figure 4. A new window will open, showing a long list of possible components. As an example, Figure 5 illustrates a list of recommended output capacitors. This example reveals a selection of 88 different capacitors from various manufacturers. You can also exit the list of recommended components and select the “Show All” option to choose from a variety of more than 4,660 capacitors. This list is continuously expanded so that the database of external components remains up-to-date.

Checking the Conversion Efficiency

Once the optimal external components have been selected, the conversion efficiency of the switching regulator is checked using the “Loss Estimate & Break Down” button. A precise diagram of the efficiency and losses is then displayed. In addition, the junction temperature reached in the IC can be calculated based on the thermal resistance of the housing. Figure 6 shows the page of calculations for the conversion efficiency and thermal behavior.

Once you’re satisfied with the circuit response, you can move to the next set of calculations. If the efficiency isn’t satisfactory, the switching frequency of the switching regulator can be changed (see left side of Figure 6), or the selection of the external coil can be changed. The efficiency is then recalculated until a satisfactory result is achieved.

Optimizing the Control Bandwidth and Checking the Stability

After selecting the external components and calculating the efficiency, the control loop is optimized. The loop must be set so that the circuit is reliably stable, not prone to oscillations or even instability while providing a high bandwidth—that is, the ability to respond to changes of the input voltage and, in particular, to load transients. The stability considerations in LTpowerCAD can be found in the “Loop Comp. & Load Transient” tab. In addition to a Bode plot and curves on the response of the output voltage following load transients, there are many setting options.

The “Use Suggested Compensation” button is the most important. In this case, the optimized compensation is employed; the user needn’t dive deeply into control engineering to adjust any parameters. For example, Figure 7 shows the setup of a control loop.

Stability calculations are performed in the frequency domain and are very fast, much faster than simulations in the time domain. As a result, parameters can be changed on a trial basis and an updated Bode plot is provided in a few seconds. For a simulation in the time domain, this would take many minutes or even hours.

Checking the EMC Response and Adding Filters

Depending on the specification, additional filters may be necessary at the input or output of the switching regulator. This is where less-experienced power-supply developers, in particular, face large challenges. The following questions pop up: How must the filter components be selected to ensure a certain voltage ripple at the output? Is an input filter necessary and, if so, how must this filter be designed to keep conducted emissions below certain EMC limits? In this respect, interaction between the filter and the switching regulator must not result in instability under any circumstances.

Figure 8 shows the Input EMI Filter Design, a sub-tool in LTpowerCAD. This can be accessed from the first page where the external, passive components are optimized. Starting the filter designer brings up a filter design using passive ICs and an EMC graph. The graph plots the conducted interference with or without an input filter and within appropriate limits from various EMC specifications such as CISPR 25, CISPR 22, or MIL-STD-461G.

The filter characteristic in the frequency domain and the filter impedance also can be displayed graphically beside the illustration of the input conducted EMC response. This is important to ensure that a filter doesn’t have total harmonic distortion that’s too high, and that the filter impedance matches the impedance of the switching regulator. Problems with the impedance match can lead to instabilities between the filter and the voltage converter.

Such detailed considerations can be accounted for in LTpowerCAD and don’t require in-depth knowledge. With the “Use Suggested Values” button, the filter design is automated.

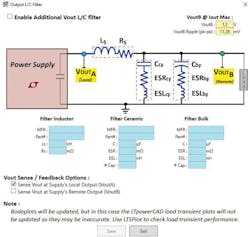

Of course, LTpowerCAD also supports the use of a filter on the output of the switching regulator. Oftentimes, this filter is used for applications in which the output voltage is only allowed to have a very low output-voltage ripple.

To add a filter in the output-voltage path, click the LC filter icon on the “Loop Comp. & Load Transient” page. Once this icon is clicked, a filter appears in a new window (Fig. 9). The filter’s parameters can be easily selected from this window. The feedback loop may either be connected in front of this additional filter or behind it. Here, a stable response of the circuit can be ensured in all operating modes despite very good dc precision of the output voltage.

Power-Supply Design Step 4: Simulating the Circuit in the Time Domain

Once you have completely designed a circuit using LTpowerCAD, simulating it is the crowning achievement. Simulations are usually run in the time domain. Individual signals are checked against time. The interaction of different circuits also can be tested on a printed circuit board. On top of that, it’s possible to integrate parasitic effects into the simulation. With this, the result of the simulation becomes very accurate, but simulation times are longer.

Generally, a simulation is suitable for collecting additional information prior to implementing real hardware. It’s important to know the potential and the limits of circuit simulation. Finding the optimal circuit might not be possible using only simulation. During simulation, one can modify parameters and restart the simulation.

However, if the user isn’t an expert in designing circuits, it can be difficult to determine the right parameters and then optimize them. As a result, it’s not always clear to the user of a simulation whether the circuit has already achieved the optimal state. A computing tool such as LTpowerCAD is better suited for this purpose.

Simulating the Power Supply Using LTspiceLTspice, developed by Analog Devices, is a powerful simulation program for electric circuits. It’s widely used by hardware developers, due to its ease of use, extended network of user support, optimization options, and reliable simulation results. In addition, LTspice is free of charge and can easily be installed on a personal computer.

LTspice is based on the Spice program, which originated from the Department of Electrical Engineering and Computer Sciences at the University of California, Berkeley. The acronym Spice stands for simulation program with integrated circuit emphasis. Many commercial versions of this program are available.

Although originally based on Berkeley’s Spice, LTspice offers considerable improvements in the convergence of circuits and simulation speed. Additional features of LTspice include a circuit diagram editor and waveform viewer. Both are intuitive to operate, even for a beginner. These features also provide a great deal of flexibility for the experienced user.

LTspice is designed to be simple and easy to use. The program, downloadable at analog.com, includes a large database containing simulation models of nearly all power ICs from Analog Devices along with external passive components. As mentioned, once installed, LTspice can operate offline. However, regular updates will ensure that the newest models of switching regulators and external components are loaded.

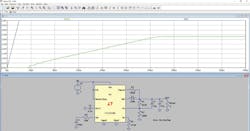

To start an initial simulation, choose an LTspice circuit in the product folder of a power product on analog.com (for example, the LT8650S evaluation board). These are usually the suitable circuits of the available evaluation boards. By double-clicking the related LTspice link in a specific product folder, LTspice will launch the complete circuit locally on your PC. It includes all external components and presets necessary to run a simulation. Then, click on the runner icon (Fig. 10) to start simulation.

Following a simulation, all of the voltages and currents of a circuit can be accessed using the waveform viewer. Figure 11 shows a typical illustration of the output voltage and the input voltage as the circuit ramps up.

A Spice simulation is primarily suited for understanding a power-supply circuit in detail so that no unwanted surprises emerge when building the hardware. A circuit also can be changed and optimized using LTspice. Furthermore, the interaction of the switching regulator with the other parts of the circuit on the PCB can be simulated, which is particularly helpful in uncovering interdependencies. For example, several switching regulators can be simulated at the same time in one run. It extends the simulation time, but certain interactions can be checked in this case.

Power-Supply Design Step 5: Testing the Hardware

While automation tools have a valuable purpose in power-supply design, the next step is to perform a basic hardware evaluation. The switching regulator operates with currents switched at a very high rate. Due to the parasitic effects of the circuit—particularly of the PCB layout—these switched currents cause voltage offset, which generates radiation. Such effects can be simulated using LTspice. To do this, however, you need precise information about the parasitic properties. Most of the time such information isn’t available. You would have to make many assumptions, and these reduce the value of the simulation result. Consequently, a thorough hardware evaluation must be completed.

Printed-Circuit-Board Layout—An Important ComponentThe PCB layout is usually known as a component. It’s so critical that, for example, it’s not possible to operate a switching regulator for test purposes using jumper wires, as is the case with a breadboard. Mainly, the parasitic inductance in the paths where the currents are switched leads to a voltage offset that makes operation impossible. Some circuits also could be destroyed due to excessive voltage.

Support is available for creating an optimal PCB layout. The corresponding datasheets for the switching-regulator ICs usually provide information about a reference PCB layout. For most applications, this suggested layout can be used.

Evaluating the Hardware Within the Specified Temperature RangeDuring the power-supply design process, conversion efficiency is considered to determine whether the switching-regulator IC operates within the permissible temperature range. However, testing the hardware at its intended temperature limits is important. The switching-regulator IC and even the external components vary their rated values over the permissible temperature range. These temperature effects can easily be taken into consideration during the simulation using LTspice.

However, such a simulation is only as good as the given parameters. If these parameters are available with realistic values, LTspice can perform a Monte Carlo analysis that leads to the desired result. In many cases, evaluating the hardware through physical testing is still more practical.

EMI and EMC ConsiderationsIn late stages of system design, hardware must pass electromagnetic interference (EMI) and EMC tests. While these tests must be passed with real hardware, simulation and calculation tools can be extremely useful in gathering insights. Different scenarios may be evaluated prior to hardware testing.

Certainly, some parasitics involved usually aren’t modeled in simulation, but general performance trends related to these test parameters can be obtained. In addition, the data obtained from such simulations can provide the insights necessary to apply modifications to the hardware quickly, in case an initial EMC test wasn’t passed. Since EMC tests are costly and time-intensive, utilizing software such as LTspice or LTpowerCAD in early design stages can help achieve more accurate results prior to testing, thus speeding up the overall power-supply design process and reducing costs.

Summary

The tools available for power-supply design have become very sophisticated and powerful enough to meet the demands of complex systems. LTpowerCAD and LTspice are high performance tools with simple-to-use interfaces. As a result, these tools can be invaluable to a designer with any level of expertise. Anyone from the experienced developer to the less experienced can use these programs to develop power supplies on a day-to-day basis.

It’s astounding how much simulation capabilities have evolved. Using the proper tools can help you build a reliable, sophisticated power supply more quickly than ever before.

Read more articles in TechXchange: Power Supply Design

Free Power Tools

- Optimization help LTpowerPlanner

- Calculation tool LTpowerCAD

- Simulation tool LTspice