Power Performance Tradeoffs in Op Amps

Members can download this article in PDF format.

What you'll learn:

- What is driving the power vs. performance tradeoffs?

- How to improve the op-amp bandwidth-to-power ratio.

- How noise, distortion, and other factors impact the power/performance design decisions.

High performance with low power consumption: This requirement is coming to bear in more and more applications, especially when it comes to mobile, battery-operated devices. Particularly in the times of IoT, Industry 4.0, and digitalization, these handhelds make many aspects of daily life easier. This is true in applications ranging from mobile vital sign monitoring to the monitoring of machines and systems in an industrial setting. Demands for higher performance and maximum battery life also are seen in end-user products, such as smartphones and wearables.

The limited battery energy available for supplying power necessitates efficient components with minimal current in active mode to maximize device runtime. Alternatively, lower power consumption allows one to achieve the same battery life with a lower capacity battery, reducing size, weight, and cost.

Temperature management also should not be neglected. Here, too, more efficient components play a positive role. Cooling management, which takes up space, can be reduced because of the lower amount of generated heat. There’s an extensive range of low-power and even ultra-low-power (ULP) components available. This article focuses specifically on low-power op amps.

Tradeoffs Between Power Consumption and Performance

Tradeoffs often are related with the power consumption of an operational amplifier that need to be considered in the selection of a suitable amplifier.

Lower power also usually means lower bandwidth. However, this depends on the given amplifier architecture and stability requirements as well. The higher the parasitic capacitances and inductances, usually the lower the bandwidth. Thus, for example, transimpedance amplifiers (current-feedback amplifiers) offer a relatively high bandwidth, but with lower precision. With a few tricks, the bandwidth-to-power ratio can be improved.

For example, the gain bandwidth (GBW) is typically as follows:

GBW = (Gm/C)

Gm is the transconductance, or the ratio between the output current and the input voltage (IOUT/VIN), and C is the internal compensation capacitance.

The classic way to increase bandwidth is to increase bias currents, which will increase Gm at the expense of more power consumption. But we don’t want to do that for lower power.

Typically, the compensation capacitance should set the dominant pole, so ideally the load capacitance wouldn’t affect the bandwidth at all.

A lower capacitance usually yields to a higher bandwidth, which is then limited by the physical characteristics of the amplifier. However, it also will hurt the stability, whereas it usually results in improved stability at a low noise gain. Nevertheless, in reality, we can’t drive as large of a purely capacitive load at lower noise gains.

Noise and Other Tradeoffs

Another tradeoff in the use of low-power op amps is the voltage noise, which oftentimes is higher. However, input-referred voltage noise will typically be the amp’s dominant contributor to the total output broadband noise, but it could be dominated by resistor noise.

Generally, the total noise is dominated by the noise sources in the input stage (for example, collectors have shot noise and drains have thermal noise). The 1/f noise (flicker noise) varies depending on the architecture and is caused by special defects in the component materials, among other things. Thus, it’s typically dominated by the component size.

In contrast, the current noise is usually lower at lower power levels. However, especially in bipolar amplifiers, it should not be neglected. In the 1/f region, 1/f current noise can be the dominant contributor to total 1/f noise at the amplifier output.

Other tradeoffs lie in the distortion performance and the drift values. Low-power op amps usually exhibit a higher total harmonic distortion (THD), but like current noise, the input bias and offset currents in bipolar amplifiers decrease with decreasing supply currents.

Another important characteristic of operational amplifiers is the offset voltage. It’s typically influenced through adaptation of the input-side components and therefore doesn’t cause any significant loss of performance at low power, so VOS and VOS drift are constant over power.

The external circuitry and the feedback resistors (RF) also affect the performance of an op amp. Higher resistance values reduce the dynamic power and the harmonic distortion, but they increase the output noise and the effects associated with the bias current.

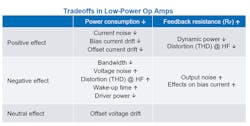

To reduce the power consumption even further, many devices often have a standby or sleep function. This enables key device features to be deactivated when not in use and only reactivated when needed. The wake-up time is usually longer for low-power amplifiers. All of these tradeoffs previously described are summarized in the table.

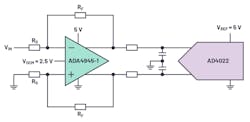

A good compromise between these characteristics is presented by the ADA4945-1 bipolar differential amplifier. Due its low dc offset, dc offset drift, and high dynamic performance, it’s well-suited for high-resolution, powerful data-acquisition and signal-processing applications in which a driver is needed for an analog-to-digital converter (ADC).

The figure shows an example of the ADA4945-1 driving the AD4022 ADC. Including multiple power modes, you can optimize the performance vs. power tradeoffs for the specific converter. For instance, its full-power mode should pair well with the AD4020, and then you can switch down to low-power mode for the lower sample rate of the AD4021 or AD4022.