Consider Realistic Voltage Sources When Designing Power Supplies

This article is part of TechXchange: Power Supply Design

Members can download this article in PDF format.

What you'll learn:

- The importance of the input-voltage range in power-supply design.

- Using simulation to ensure the switching regulator is operating properly.

A power supply’s source, in actual use, is never ideal. The real behavior, including parasitics, must be considered to build a reliable power system. When we use power supplies, we ensure that a dc-dc converter, such as a switching regulator, can withstand a certain input voltage range and generate the required output voltage from it with sufficient current.

The input voltage is frequently specified as a range because it’s usually not regulated exactly. For a power supply to function reliably, though, there must always be an input voltage within the permissible range available to the switching regulator.

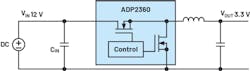

For example, a typical input voltage range for a 12-V supply voltage may lie between 8 and 16 V. Figure 1 shows a step-down converter (buck topology) that generates 3.3 V from a nominal voltage of 12 V.

However, when designing the dc-dc converter, it’s not sufficient to only consider the input voltage minimum and maximum values. Figure 1 shows that the buck converter has a switch at its positive input. This switch is turned on or off. The switching speed should be as high as possible so that only low switching losses occur, but this causes a pulsed current to flow on the supply line.

Not every voltage source can deliver such pulsed currents without any problems. As a result, voltage drops occur at the input of the switching regulator. To minimize this, backup capacitors are required right at the input of the power supply. This type of capacitor is presented as CIN in Figure 1.

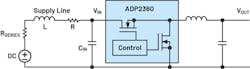

Figure 2 depicts the circuit from Figure 1, but this time with the parasitic elements of the supply line and the voltage source itself. The internal resistance of the voltage source (RSERIES), the inductance and the resistance of the supply line (R, L supply line), and any current limitation are key voltage-source characteristics that must be considered to guarantee trouble-free operation of the switching regulator.

For the most part, the correct selection of the input capacitors can ensure proper operation of the circuit. The first approach should be to take the recommended capacitance value for CIN from the datasheet for a switching-regulator IC. However, if the voltage source or the supply line exhibits special characteristics, it makes sense to simulate the combination of the voltage source and the switching regulator. Figure 3 shows a simulation performed with the LTspice simulation environment from Analog Devices.

A simulation circuit for the ADP2360 buck converter is shown in simplified form in Figure 3—the input voltage IN is generated with an ideal voltage source. Because no internal resistance is defined for the voltage source and no parasitic values are given for the supply line between the voltage source and the switching regulator, the defined voltage is always applied to the VIN pin of the ADP2360. Therefore, it’s not necessary to add an input capacitor (CIN).

In the real world, though, an input capacitor is always required with a switching regulator because the voltage source and the supply line aren’t ideal. If a simulation environment such as LTspice also is used to check the behavior with different input capacitors, a voltage source with internal resistance and a supply line with parasitic values for resistance and inductance (Fig. 2, again) must be used.

Read more articles in TechXchange: Power Supply Design