This Week in PowerBites: Clever Current Sensors and a Bruising Battlebot

This article is part of the This Week in PowerBites Library Series

Nigeria's First Indigenous eBikes Blaze a Path for Electrifying African Transit

ThinkBikes, a scrappy Nigerian startup, is aiming to kickstart the country's transition to electric transportation by manufacturing rugged, affordable eBikes using largely local materials and labor. Founded by Olugokun Tolulope, CEO of Think Electric Africa and a former a professor of engineering, the company serves the so-called micro-mobility market with locally manufactured two- and three-wheel pedal vehicles for last-mile transport of goods and people.

The company is currently tooling up to introduce the Alpha 1. It’s an electrified version of their rugged pedal truck, which provides users with greater speed, range, and cargo capacity.

According to Olugokun, local production enables ThinkBikes to sell vehicles that are optimized for use in Africa to sell for 40% less than their imported counterparts. He also says that local production boosts the local economy and helps build a community of people with the skills, resources, and networks necessary to manufacture larger EVs, or other complex products.

For additional details, read the full story here.

Robot Lib? Smart Wireless-Charging Platform Frees Consumer and Commercial Robotics

Powermat Technologies announced a full-featured wireless-charging solution designed to charge and optimize charging efficiency for fleets of various types of service robots. Some of the platform’s anticipated applications include photovoltaic-powered robots used for commercial cleaning, delivery, warehouse operations, and medical operations.

The platform addresses one of the challenges faced by most autonomous mobile robots (AMRs) today. Despite their advanced autonomous capabilities, robots with self-charging capabilities still have trouble docking and charging properly. It results in downtime for the operations they support, as well as the cost of human intervention and maintenance.

The new platform uses Powermat's SmartInductive technology, a hybrid approach that bridges the gap between magnetic induction and resonance. It can deliver up to 300 W at distances reaching 150 mm between receiver and transmitter (Z) at up to 90% charging efficiency. Thus, robots can re-power in proximity to their charging station without the need for accurate alignment or direct contact.

Other than a supporting higher power transmission levels, the commercial robotics platform functions precisely like that portrayed in this video of the technology applied to a domestic robot:

Powermat's turnkey reference design also provides connectivity features that combine power and in-band data transfer. This allows for seamless communication between each robot in the fleet and at docking stations, which is required for identification and authentication, software upgrades, and more. Powermat's solution for commercial robotics features a software-based interface to enable analytics, fleet management, and other AI-powered data capabilities.

For more information, visit https://powermat.com/wireless-charging-technology-for-robots/

3 Converters that Give You More Buck for Your Buck

The humble buck converter has entered a new stage of rapid evolution, driven in large part by the growing role of the USB-C/PD standard as the power supply of choice for mobile electronics, and a quite a few stationary applications. Meanwhile, mobile electronics designers are demanding regulators/converters that can maximize their products' operating times while reducing overall BOM count and solution size. In this issue of PowerBites, we're including three recently introduced products that exemplify these trends.

Single-Stage Step-Down Buck Converter Saves Space in Multi-Cell Battery Apps

The MAX77540 step-down buck converter developed by Analog Devices Inc. (ADI) provides single-stage power conversion in multi-cell battery applications, such as augmented-reality/virtual-reality (ARVR) headsets, land mobile radios (LMRs), and DSLR cameras. The power-dense MAX77540 buck converter features 94% peak efficiency and wafer-level packaging that measures 61% smaller than traditional quad flat no-lead (QFN) packages.

Traditional multi-cell converters employ multi-stage architectures. Such architectures are inefficient and need an additional converter, which often requires an inductor, ultimately resulting in a larger solution footprint and higher cost.

With the MAX77540, the design engineer can easily create either dual 3A or a single 6A output(s). Default power on configuration only requires two external resistors. The regulator's integrated I2C interface allows for further control for advanced power-management techniques. External frequency tracking and spread-spectrum modulation provide low electromagnetic-interference (EMI) power conversions for data sensing and processing equipment.

MAX77540 Key Features

- Wide 4- to 16-V input voltage range and two 3-A switching phases provide single-step conversions to core voltages from USB-C rails and 2S and 3S multi-cell batteries.

- Wafer-level package measures 61% (2.5X) smaller than traditional QFN packaging to fit in the most space-constrained applications.

- 94% peak efficiency measured at 7.4 V to 3.3 V extends battery life.

Availability and Packaging

The MAX77450 is available now in 2.51- × 2.31-mm, 30-bump wafer-level packaging. An evaluation kit, the MAX77450EVKIT, is also available now. You can download a datasheet and order samples and evaluation boards at https://bit.ly/MAX77540Product.

Digitally Programmable 60-W Synchronous Buck Converter Targets USB PD

Featuring a synchronous topology for optimum efficiency, the STMicroelectronics STPD01 digitally programmable dc-dc buck converter can provide up to 60 W for USB Power Delivery (PD) applications, such as ac multiport adapters, USB hubs, PC monitors, and smart televisions.

Able to accept supply voltages ranging from 6 to 26.4 V, the converter’s output voltage can be digitally adjusted (via I2C) between 3 and 20 V in 20-mV minimum steps, as defined in the USB-PD specification. The STPD01 also incorporates cable-drop compensation with an internal voltage-feedback resistor divider. This ensures the load receives the correct voltage, unaffected by losses in copper tracks and the attached output cable.

To simplify designs, the device features integrated protection against overvoltage, overcurrent, and overtemperature. Additional built-in features include embedded discharge circuitry, soft-start, undervoltage lockout, and a programmable watchdog timer that helps ensure a robust and safe system.

Powerful Development Tools

To accelerate development of solutions based on the STPD01ST, ST launched the STEVAL-2STPD01 USB Type-C PD dual-port adapter kit. Created as an expansion card to be used with the NUCLEO-G071RB STM32 Nucleo-64 development board, the STEVAL-2STPD01 board contains two Type-C ports with two STPD01 programmable buck converters.

Two TCPP02-M18 protection ICs for USB Type-C and PD Source applications also are on-board, and the associated software package, STSW-2STPD01, contains a sample application to run on the STM32G07 microcontroller. The STEVAL-2STPD01 kit is available now at ST’s eStore.

The STPD01 is in production and ready to order now, packaged in a 3- × 4-mm QFN24L. It’s priced at $1.58 for orders of 500 pieces. For additional information, go to www.st.com/dcdc.

Ref Board Supports Development of 35-W Adapters, Chargers Using Silicon or GaN FETs

Eggtronic has released a development board that implements the reference design for a compact, highly efficient, 35-W ac-dc converter circuit. It’s intended to speed the design, prototyping, and implementation of high-performance, high-efficiency, ultra-compact power converters, power adapters, and device chargers.

The new reference design is based on the same EcoVoltas QuarEgg+ technology used in the 60-W ac-dc converter featured in the January 20 edition of PowerBites. Suitable for both USB-PD and fixed power output applications, the board is available with a gallium-nitride (GaN) FET (for maximum performance) or a silicon FET (for cost-effective high-performance solutions).

The compact architecture boosts the performance of FET switching devices, regardless of whether they’re based on legacy silicon or wide-bandgap (WBG) materials. EcoVoltas QuarEgg+ micro-sized power converters offer up to 5X lower losses and are twice as small as traditional silicon converters, and up to two times lower losses and 30% smaller than previous GaN converters.

Measuring just 38.3 × 38.3 × 18.6 mm, the new reference board integrates all of the components required to deliver a working USB-PD or fixed-output converter that delivers a peak efficiency in excess of 94%, plus a very flat efficiency curve and no-load power consumption of less than 18 mW. It can accommodate a wide input voltage range of 90 to 264 V ac. Configurable output options are 5 V/3 A, 9 V/3 A, 12 V/2.9 A, 15 V/2.3 A, and 20 V/1.75 A.

Another version of the development board that features easy access to every electrical test point also is available. Both boards can be ordered at https://www.eggtronic.com/quaregg/

Department of Current Affairs

While semiconductors are the stars of the power technology world, the applications they power also rely heavily on a supporting cast of other components, such as current sensors. In this issue, we're highlighting a couple of recent developments in current sensing that will help us create more cost-effective, reliable, and efficient designs.

AMR-Based 65-A Current Sensor for WBG Power Applications

ACEINNA recently introduced a higher-powered member of its family of anisotropic-magnetoresistive-based (AMR) current sensors. Rated at ±65 A, the MCx1101 series is designed specifically for applications that use wide-bandgap (WBG) power devices and offers industry-leading accuracy and bandwidth. These new current sensors deliver a typical accuracy of ±3%, fast response, and 4.8-kV isolation, suiting them for current sensing in fast current control loops and protection for high-performance power supplies, inverters, and motor-control applications.

With an output step response time of 0.3 ms and 1.5-MHz signal bandwidth, the MCx11-1 can accurately monitor the response of fast-switching SiC- and GaN-based power stages. It also provides an integrated overcurrent detection (OCD) flag signal that can be used to implement the protection required in modern power systems. Overcurrent detection response time is a fast 0.2 µs.

The sensor is housed in an industry-standard SOIC-16 package that provides a low-impedance (0.9 mΩ) current path. It’s UL/IEC/EN60950-1 certified for isolated applications. Available in 3.3- and 5-V versions, this current sensor is ideal for many next-generation power systems and applications.

ACEINNA’s current sensor family, which also includes ±50-, ±20-, and ±5-A ranges, is offered in both fixed-gain (MCA1101) and ratiometric-gain (MCR1101) versions.

Units are now available for sampling and volume shipments. For additional technical details, the ACEINNA MCA1101 and MCR1101 datasheets are located at https://www.aceinna.com/current-sensors. Further information is available at [email protected] or https://www.aceinna.com.

Thick-Film Shunt Resistors Offer 4-W Rated Power + High Accuracy

ROHM Semiconductor added several new members to its LTR100L family of thick-film shunt resistors, which expand the series' rated power range to 4 W. Like all members of the LTR100L series, they’re optimized for industrial and consumer applications, such as battery protection systems and motor-drive circuits, which require higher accuracy to improve reliability and ensure high-efficiency operation. Applications for the LTR100L include:

- Industrial equipment (factory automation, motor peripheral circuits, power supplies)

- Consumer appliances (air conditioners, washers, refrigerators, vacuum cleaners)

- Other (two-wheel vehicle headlamps, EV scooters aka e-bikes, etc.)

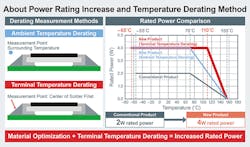

ROHM achieved the industry’s highest rated power for the 3264 (3.2 × 6.4 mm) and 1225 (0.12 × 0.25 in.) form factors by utilizing improved resistor materials and applying terminal temperature derating (see image below). In addition, their optimized element structure gives the thick-film shunt resistors excellent temperature coefficient of resistance (TCR) characteristics, which enable high accuracy and reliability for current detection in motor-control and overcurrent protection circuits used in industrial and consumer products.

Documentation and Design Support

Documentation, application notes, and design tools for the LTR100L family are available on ROHM’s website. This includes a web-based simulation environment that enables thermal simulation of shunt resistors in combination with power devices and ICs (starting with the PSR series). Click on the following link to access the dedicated website and register as a user to begin using the ROHM Solution Simulator: https://www.rohm.com/solution-simulator

Eating Their Own Robo-Dog Food: STEM Component Manufacturer Puts Its Products to the Test in the Battlebot Arena

REV Robotics is well-known for designing and manufacturing high-quality robotics parts, components, and kits for students participating in the FIRST Robotics competition and classroom-based STEM programs. One of the secrets to its success is the fact that many of its own products are used in the rugged dangerous fighting machines it builds to compete in the Discovery Channel's "Battlebots" show.

Team REV's most recent creation is “Switchback,” a 250-lb. battlebot designed to ram opponent robots to disable them and then break them apart with a dual-motor drum spinner mounted on a fully ambidextrous arm. In addition to being a dangerous competitor, the robot has been designed for durability and serviceability to enable its survival.

In addition to REV Robotics, the team is supported by several other sponsors, including STMicroelectronics, which supplies the team with many of its essential power electronics and sensors. Switchback uses five of ST's heavy-duty electronic speed controllers to inflict precisely controlled mayhem on its victims via drive motors in the left-side and right-side drivetrain, its ambidextrous arm, and the arm-mounted weapons.

Each controller is driven by open-source firmware, running on a STM32 MCU. REV Robotics chose the controllers for their durability and REV’s previous familiarity with the ST microcontrollers inside, which helps the team make firmware changes to the MCUs quickly.

“The latest in a line of take-no-prisoners battlebots, Switchback builds on our long interest in robots and our experience in these entertaining—but serious—competitions to encourage the next generation of engineers, who can also use our parts and kits to develop the same passion and excitement for robotics that we have,” said Greg Needel, President and Co-founder, REV Robotics.

A Little More About REV Robotics

Based in North Texas, REV Robotics designs and manufactures products that serve both the classroom and competitive robotics markets. REV products are used by more than 10,000 schools, across 190 countries globally. REV Robotics is passionate about increasing STEM education accessibility and global impact to support the creation of the next generation of STEM professionals.

Read more articles in the This Week in PowerBites Library Series