eFuses Raise the Bar in Features, Functions, Capacity, Connectivity

Nearly every circuit or subsystem, even those modest sub-one-amp designs, often needs a fuse to protect its own components or the load against internal and external faults. Thermally activated passive fuses have been around “forever”—they do one thing, they do it well, and their reliability is unchallenged. But these classic fuses can’t provide the more complicated functions and features needed to meet the multifaceted requirements of many of today’s systems.

That’s where the electronic fuse (eFuse) plays an increasing role by implementing a radically different approach to overcurrent sensing and cutoff. These active devices are a natural fit where fast response, accuracy, programmability, and resettability are needed, among other characteristics.

This allows them to cope with both permanent and transient conditions, including nuisance situations such as hot swapping of PCBs (which might blow a conventional fuse due to the inrush transient, yet there’s no actual problem). Systems that are good fits for eFuse characteristics include server and high-performance computing systems; network interface, graphics, and accelerator cards; data-center switches and routers; and even the humble fan tray.

At the same time, eFuses have the potential to do even more. Designers now want “extras” such as the ability to use fuses in parallel scaled to the design and—even more distant from traditional fuses—basic connectivity to provide remote initialization and monitoring.

eFuses that Extend the Boundaries

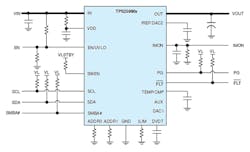

Recognizing these requirements, two new eFuses from Texas Instruments go far beyond what’s possible or available with thermal fuses or even basic eFuses. The TPS25985 is a 4.5- to 16-V, 0.59-mΩ, 60-ARMS (80-A peak) stackable eFuse with an accurate and fast current monitor. The similar TPS25990 is a 2.9- to 16-V, 0.79-mΩ, 50-ARMS (60-A peak) eFuse that adds the additional feature of PMBus Digital Telemetry (Fig. 1). TI maintains that these eFuses have the industry’s highest current rating.

After a startup situation-assessment sequence, these devices actively monitor their load current and input voltage. They also control the internal FET to ensure that the user-set overcurrent threshold isn’t exceeded and input overvoltage spikes are cut off. This action fulfills the primary mission of keeping the system safe from harmful levels of voltage and current.

At the same time, a user-adjustable overcurrent blanking timer allows the system to pass transient peaks in the load current profile without tripping the eFuse. Similarly, voltage transients on the supply line are intelligently masked to prevent nuisance trips. This feature ensures a robust protection solution against real faults that’s also highly immune to transients, thereby ensuring maximum system uptime. Response time is fast and accuracy is high—better than 200 ns with ±1.4% accuracy for the TPS25985 and 280 ns/±2.1% for the TPS25990.

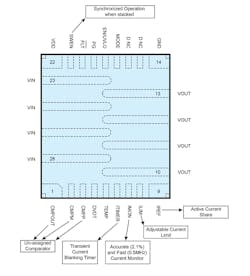

Due to their high level of integration, the eFuses eliminate the need for many external components. The small package size (4.50- × 5.00-mm QFN26, with other packages available as well) enables designers to reduce solution size and achieve better thermal performance; note that the package pinout is unusual, as it’s tailored the unique requirements of eFuses (Fig. 2).

Going Parallel, Adding Connectivity

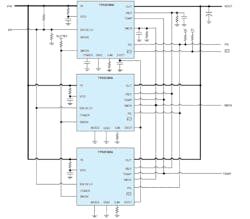

Note that conventional hot-swap controllers can’t control the gates of multiple paralleled MOSFETs very precisely; thus, current sharing by paralleled MOSFETs isn’t accurate. Also, it’s challenging to gauge the die temperature of the MOSFET, and therefore impossible to guarantee its thermal protection in transient and steady-state conditions.

This problem can be overcome by adding precision amplifiers to achieve high current-share accuracy and current-monitor accuracy. However, doing so increases the solution complexity, cost, and size.

The TPS25985 and TPS25990 eFuses maintain integrated, active current sharing and direct access to MOSFET die parameters (voltage, current, temperature), which allows accurate control of all eFuse gates connected in parallel and accurate die temperature monitoring of integrated FETs. They provide scalable solutions, as designers can use multiple devices in parallel for 300 A or higher current systems while optimizing BOM cost without overdesigning the system (Fig. 3).

But why stop there? When “mere” fusing isn’t enough, the integrated PMBus interface of the TPS25990 allows a host controller to monitor, control, and configure the system in real-time. Key system parameters can be read back for remote telemetry, and various protection, warning thresholds, and coefficients can be configured through the PMBus or stored in non-volatile configuration memory. In addition, the Blackbox fault recording feature supports debug of field failure/returns.

Even eFuses Can Use Support

Design-in support begins with a 69-page datasheet for the TPS25985 and spreadsheet Design Calculator as well as a corresponding 74-page datasheet for the TPS25990 and spreadsheet Design Calculator. The calculators simplify the task of working out associated component values and timing. There’s also the TPS25985EVM evaluation module ($249) for the TPS25985 that comes with a 36-page User’s Guide complete with schematic, BOM, and operating procedures (Fig. 4).

Reference

Texas Instruments, “How a fully-stackable eFuse can help meet ever-increasing power needs of servers.”