Upgrade or Replace: The MIL/Aero ATE Dilemma

MIL/Aero ATE systems with RF/microwave test capabilities are designed to be used for a number of years before being upgraded or replaced. However, the need to continue supporting legacy test program sets (TPS) greatly influences upgrade/replace decisions. Sometimes, these are prompted by test-instrument obsolescence. Other times, technology becomes available that could significantly improve the original ATE specification.

Darren McCarthy, technical marketing manager RF test at Tektronix, discussed some aspects of legacy system support. “Taking advantage of new technology to improve performance and reduce cost is a part of the technology curve,” he said. “However, the long tail of support in the MIL/Aero community requires a deliberate strategy for your legacy [equipment].

“Provided there are consistent form factors and power consumption,” McCarthy continued, “hardware innovation can be managed and even enhanced when more functionality can be placed in the same instrument category. Hardware advances actually can become a compelling reason for change when they assist to replace functionality in a reduced form factor.”

After hardware, McCarthy listed software and emphasized the adoption of Windows in high-performance instruments. He explained, “Migrating measurement-intensive computations to computer processes and PC environments not only benefits from speed enhancements with increases in processing power but, by using Windows-based platforms for measurements, actually assists with support of legacy measurements. When software becomes de-embedded from the instrument, portability helps with service-life support.”

Connectivity was the third area McCarthy stressed as important in a legacy-equipment support strategy. LXI is more flexible than chassis-oriented formats such as VXI and PXI but requires each instrument to supply adequate power and cooling. On the other hand, chassis supporting the multicomputing upgrade to PXIe provide multi-gigasample/s backplane data paths and peer-to-peer communications. As attractive as LXI and PXIe are, the latest eCASS ATE is based on VXI, largely because of legacy TPS issues.

Hardware

ZTEC’s President Christopher Ziomek cited a current example of a hardware module and the legacy concerns involved in its selection. “ZTEC’s ZT8441 IF Digitizer was chosen as the baseband processing engine for the RF/microwave subsystem on eCASS.” He noted, “The eCASS program requires 15-year integrations and support, and ZTEC is committed to ensuring instrument availability for Lockheed Martin and the U.S. Navy. This may include instrument modernization or redesign to address part obsolescence.”

The ZT8441 is an IF/RF digitizer that features a DC to 1-GHz frequency range and instantaneous IF bandwidth of 100 Hz to 160 MHz, sufficient for 802.11ac. The instrument is based on dual 400-MS/s, 14-bit ADCs and provides greater than 80-dB spurious-free dynamic range (SFDR). Like many ZTEC products, the ZT8441 is available in PCI, PXI, LXI, and VXI formats.

Ziomek cited the increased data rates of commercial wireless technology as the stimulus for a new generation of semiconductor devices. “For example, new data converters increase sample rates with more bits of resolution for IF direct sampling within the RF signal processing chain,” he said. “These new converters enable relatively simple architectures for wide instantaneous-bandwidth RF and microwave instruments.”

Figure 1. Model GT-2550B Signal Generator

Courtesy of Giga-tronics

Improved capabilities also have helped Giga-tronics address new market opportunities. Mark Elo, vice president of marketing, discussed three key application areas in which the company’s Model GT-2500B RF/Microwave Signal Generator is being used (Figure 1). In the first application, Elo said, “The generator’s fast switching CW signal helps to evaluate next-generation Doppler-based radars deployed to improve boarder security and detect insurgent activity. The transition from targets flying at supersonic speeds to slow-moving targets moving at walking or vehicle speed benefits by providing low close-in phase noise levels.”

Elo also addressed the second and third areas. “As the need to get very accurate radar images of ground activity increases, often from a UAV-mounted radar, high-resolution narrow-pulsed radars sometimes are required. The GT-2500B narrow pulse-generation capabilities solve this problem. And,” he concluded, “avoiding detection from hostile EW devices is another key driver in the market. Defense systems need to have better frequency agility and/or higher frequency capability. The GT-2500B Series of sources has fast switching speeds and frequency ranges to 50 GHz.”

Continuing the hardware theme, Agilent Technologies’ Chris Van Woerkom, aerospace and defense applications team lead, said the company had developed new chipsets for both signal generation and analysis with higher bandwidth and signal fidelity than previously available. “For instance, previous Arbs that provided greater than 2 GHz of bandwidth had around 50 dB of SFDR,” he said. “Our new 5-GHz bandwidth M8190A Arb has 60 to 80 dB SFDR (signal dependent) for multigigahertz bandwidth signals.”

Agilent’s 90000-X InP-based oscilloscope series with 33-GHz bandwidth is another example of new hardware that supports increased performance. The instruments have a combination of wide bandwidth, flatness, and noise floor that was unavailable in the past.

Figure 2. Model MDO4104-6 Oscilloscope

Courtesy of Tektronix

Advances in high-performance scope bandwidth also have been announced by Tektronix, but the company’s major improvement to its mid-price 4000 Series was the addition of spectrum analyzer capabilities. As well as four analog and 16 digital channels, the MDO4000—MDO for mixed-domain oscilloscope—includes a separate 6-GHz RF input (Figure 2). Key to effective use of the functionality is the instrument’s measurement and display correlation across the time and frequency domains.

Tek’s Real-Time Spectrum Analyzers are good examples of instruments that use a different hardware design to address modern test requirements. The company’s McCarthy explained, “Spectrum analyzer manufacturers will tend to bypass or remove preselected filtering to provide wideband analysis above a few gigahertz. Instead, Tektronix uses a series of front-end band-pass filters that support both wide bandwidth and dynamic range at microwave frequencies.”

Finally, the company’s AWG7000 Series Arbs provide an alternative approach to complex signal generation without the restrictions of limited protocol generators. With a 24-GS/s sample rate, these Arbs can generate signal bandwidths to 9.6 GHz and provide the opportunity for direct wideband IF-to-microwave up conversion without the need for IQ modulators.

Modular construction within a box instrument offers many of the advantages afforded by overtly modular test formats such as PXI or VXI. Agilent’s Van Woerkum said that the company’s X-Series Signal Analyzers all have replaceable CPU and I/O subsystems. This helps to keep a model in production for a longer time and presents the opportunity for increased performance where applicable.

Software

The phrase “the software is the instrument” long has been associated with National Instruments (NI). Indeed, many of NI’s hardware products provide well-defined functions such as digitizing or generating a signal, but it is the software that customizes the manipulation and presentation of the data. As the company’s David Broadbent, product marketing manager RF and wireless test, explained, this approach is attractive to MIL/Aero ATE planners because “test systems built with modular architectures have a better chance of obsolescence mitigation without a major system overhaul.”

Figure 3. Model NI PXIe-5665 VSA

Courtesy of National Instruments

As an example, Broadbent discussed the complementary roles of hardware and software in a recently introduced product. “The PXIe-5665 VSA (Figure 3) provides -129-dBc/Hz phase noise at a 10-kHz offset at 800 MHz, an average noise level of -165 dBm/Hz, TOI of +24 dBm, and high dynamic range. Both lower cost and higher speed are benefits of the PXI platform,” he said.

“The VSA is designed to leverage the advantages of multicore computing architectures and parallel programming capabilities through LabVIEW system design software. The opportunity to stream data peer-to-peer from the VSA to PXI FPGA processing modules makes the platform ideal for MIMO phase-coherent measurements,” Broadbent concluded.

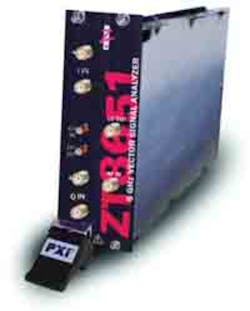

Figure 4. Model ZT8651 VSA

Courtesy of ZTEC Instruments

ZTEC’s Ziomek described the company’s ZT8651 VSA as having a software-defined architecture (Figure 4). “The ZT8651 VSA is a fixed hardware block that covers bands up to 6 GHz and offers 160-MHz instantaneous bandwidth,” he said. “The VSA’s adaptability comes not through hardware modifications but rather via its highly flexible software and firmware architecture. Onboard DSP and FPGA technologies make wireless signal and spectrum analysis functions very flexible and adaptable.

“For example,” he said, “ZTEC’s VSA uses FPGA-based digital down conversion and DSP-based FFT analysis. Using firmware and software upgrades, the same hardware can be adapted for different or new communications protocols. The same hardware block can be reprogrammed as an MTA for eCASS or as a military radio receiver to address security and electronic warfare with broadband modulation requirements.”

A third VSA implementation, Agilent’s 89600 VSA software, is an instance of measurement software that is not embedded in an instrument. It has been available for several years and continues to be updated to address the latest modulation schemes.

According to the company’s Van Woerkom, “Our 89600 VSA software supports more than 70 signal standards and modulation types including custom modulations. The software works with our spectrum analyzers, oscilloscopes, and even with our digital products. A customer can track a custom OFDM waveform as it is first generated inside an FPGA and then through digital buses, IF, and RF to see where any impairments are generated throughout the entire design.”

Figure 5. Model M9392A VSA

Courtesy of Agilent Technologies

Van Woerkum said many of Agilent’s box and modular instruments could be considered software-defined instruments. For example, he continued, “The modular M9392A VSA (Figure 5) allows easy substitution of modules to accommodate changing needs in bandwidth, digitization rates, and depths. Our procedures ensure that system calibration can be maintained even after performing such upgrades. The 89600 VSA software supports such capabilities as flexible OFDM so new protocols can be supported even if they are custom or not yet standardized.”

Aeroflex’s 7200 Configurable Automated Test Set also features a synthetic instrument platform. As stated on the company’s website, “The 7200 belongs to our 7000 Series and is based on the new Aeroflex Common Platform (CP)…. State-of-the-art hardware and software architectures, leveraging open industry standards, allow Aeroflex to configure CP products to match customer needs while providing them with upgrade and obsolescence protection in the future.”

The company’s recently introduced signal generators and analyzers are standalone instruments that feature advanced versions of the 7200’s touchscreen-control interface. According to website information, “Buttons, rotary controls, and deeply nested software menus have all been removed…. The touchscreen interface… allows modulated or swept RF signals to be set up and analyzed using fewer keystrokes than required by traditional soft key models…. The series now includes the SGA Analog RF Signal Generators, SGD Digital RF Signal Generators, and SVA RF VSGs.”

Embedded software tools support generation and analysis of complex wideband modulated signals. In addition to generating and measuring wireless communications signals, the SGD and SVA perform generic modulation and demodulation, making them suitable for general-purpose RF test.

Continuity

Just as your personal financial situation may not allow you to replace your car when you had planned, there are many reasons that MIL/Aero ATE continues to be used for years beyond its originally scheduled lifetime. Avoiding, mitigating, and, above all, managing obsolescence are key to maintaining a test system’s productivity.

Agilent’s Van Woerkum said, “We have a whole host of programs to help MIL/Aero customers with extended support. Our instruments have a guaranteed five-year support life once out of production. For selected products, we have significantly extended this life. We have a ‘Tech refresh program’ that helps customers decide when to extend vs. selectively replace equipment as well as backwards compatibility modes and emulators, asset management services, and trade-in/trade-up programs. We can continue to calibrate most instruments well beyond their production life.”

NI’s Broadbent described some of the steps his company is taking to address the obsolescence issue. “Successful deployment of test systems based on COTS technologies involves more than just the products themselves,” he said. “Upfront life-cycle planning is essential, especially for very long-term projects. Essential planning steps include understanding the desired lifetime of the system you’re testing, then understanding the roadmap and lifetime of the components used in your test system, and finally identifying project phases where there will be an opportunity to upgrade technology to elongate life.”

He explained, “We understand that our customers face many questions when developing a comprehensive lifecycle plan, including planned and budgeted technology refreshes, long-term service and repair contracts with suppliers, and last-time buys of components. Since long-term support of test systems is very much a partnership between customer and vendor, NI also is implementing new processes and services to address long-term support requirements.

“NI is enhancing its product life-cycle planning process to provide better upfront planning and advanced notice of impending EOL issues while offering a variety of life-cycle-related services, including up-front life-cycle planning, sharing of product roadmaps, product change notifications, and extended support agreements,” Broadbent added. “These processes and services apply to NI RF products as well as the rest of its instrumentation, controller, and software products.”

Because of a more narrow market focus, Giga-tronics has approached the problem a bit differently, as explained by the company’s Elo, “We spend time on ensuring our component supply chain has an adequate supply and engineer replacement parts when they are required. We keep our suppliers close and manufacture in the United States for primarily the MIL/Aero markets and do not have the commercial applications demands of other suppliers.”

Summary

The latest instruments from all these companies often can perform the same tests as legacy equipment. Some of the new products have legacy modes that identically duplicate the performance of earlier equipment, including restricted functionality and range limits. However, it is only by upgrading to the newer technology that today’s wide bandwidth communications systems can be thoroughly tested.