Modular Instruments Address 802.11ac

Wireless LAN, driven by the forthcoming IEEE 802.11ac standard, is poised for significant growth as Wi-Fi capabilities are added to a host of product categories ranging from automobiles to network-attached storage.

According to research from NPD In-Stat, as the demand for devices with Wi-Fi connectivity grows, prices for chipsets will decrease, and Wi-Fi will increasingly penetrate markets traditionally dominated by other wireless connectivity standards, including smart meters, wireless mice, and home-automation systems.1 In-Stat predicts sales of Wi-Fi chipsets will reach $6.1 billion in 2015—the year when 802.11ac chipset shipments will surpass 650 million. By 2015, the firm reports, the three biggest markets for 802.11ac will be smartphones, notebooks, and tablets.

Although the 802.11ac standard remains unratified, chipsets and consumer products are appearing. In April, for example, NETGEAR announced the availability of the R6300, which the company called the first 802.11ac dual-band gigabit Wi-Fi router. It incorporates Broadcom’s 5G Wi-Fi IEEE 802.11ac chips. NETGEAR said the new router is up to three times faster than 802.11n routers. It will offer speeds of up to 1,300 Mb/s in the 5-GHz band.

On the occasion of Broadcom’s rollout of the 802.11ac chips at January’s Consumer Electronics Show (CES) in Las Vegas, Mark Hung, a research director for wireless markets at Gartner Research, said, “Wi-Fi-enabled devices will grow from less than 1 billion units in 2010 to more than 3 billion in 2015.2 Given the current constraints of legacy 802.11 standards and the increased speed, capacity, coverage, and battery life that 802.11ac offers, this next generation of Wi-Fi is poised for rapid growth across all product segments. 802.11ac will be one of the most influential mobile and wireless technologies in the years to come.”

Broadcom introduced several 5G Wi-Fi chips at CES. The BCM4360 supports the PCIe interface and implements three-stream 802.11ac specifications, reaching speeds up to 1.3 Gb/s. The BCM4352 (with a PCIe interface) and BCM43526 (with a USB interface) implement two-stream 802.11ac specification to reach up to 867 Mb/s. BCM43516 supports USB and reaches speeds of up to 433 Mb/s with its single-stream 802.11ac implementation. All the chips support 80-MHz channel bandwidth (twice that of 802.11n) and 256-QAM and transmit and receive beamforming. (Broadcom calls the emerging 802.11ac technology 5G WiFi and provides more information on the www.5gwifi.org website that it maintains.)

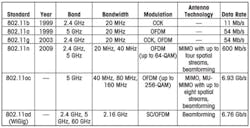

Table 1. Wireless LAN Evolution at a Glance

As IEEE 802.11 evolves (Table 1), test vendors are striving to keep up. The 802.11ac standard’s bandwidth, modulation scheme, and beamforming capability—coupled with additional features such as support for up to eight MIMO (multiple-input/multiple-output) spatial streams—all present significant challenges for test. Some of these challenges are particularly amenable to being met with modular test systems.

Three Ways to Boost Throughput

David A. Hall, a product manager for RF and wireless test at National Instruments, elaborated on the challenges of 802.11ac test in an edition of the company’s Instrumentation Newsletter.3 There are three strategies for increasing throughput, he wrote: employing higher order modulation schemes, increasing channel bandwidth, and increasing the number of spatial streams, and 802.11ac will make use of all three by supporting 256 QAM modulation, 80-MHz or optionally 160-MHz bandwidths, and supporting up to 8×8 MIMO. With respect to modulation, he noted, “While 256-QAM and even 1,024-QAM have already been adopted by some wireline communications systems such as DOCSIS [Data Over Cable Service Interface Specification] 3.0 digital cable, nothing more complex than 64-QAM has ever been adopted in a mass market consumer product until now.”

Regarding bandwidth, he noted, “The 802.11ac very high-throughput specification actually supports 20-MHz, 40-MHz, and 80-MHz bandwidths. In addition, it has two 160-MHz options, one with a contiguous 160-MHz carrier and one with two separate 80-MHz carriers.” Furthermore, he noted that 8×8 MIMO would allow for double the maximum spatial streams of 802.11n’s 4×4 MIMO implementation.

Raajit Lall, product marketing manager for RF and wireless test at NI, said, “PXI is ideally suited to address the test challenges related to wireless devices including 802.11ac due to its flexibility, fast test times, and lower overall cost. The modularity of PXI enables test engineers to build the best solution for their applications whether it is a VSA and VSG for transmit and receive tests or more complex MIMO systems that also incorporate power control, high-speed digital, and other functionality.”

He added, “PXI solutions are inherently software defined where modulation and demodulation are decoupled from the PXI hardware.” That, he said, makes a PXI system flexible enough to handle a variety of different standards, such as WLAN, Bluetooth, GPS, and 2G/3G/4G cellular standards.

NI’s pre-released PXI systems for 802.11ac test have been used in both R&D and production testing, Lall said, adding that in R&D, “You tend to see the need for the higher RF performance, MIMO configurations, and interactive 802.11ac software interfaces. In production, you tend to see the need for fast test times, lower cost deployments, and more integrated test solutions.”

VSA for MIMO Test

ZTEC Instruments is another company addressing 802.11ac, and the company already offers a vector signal analyzer (VSA)—the ZTEC ZT8651—suitable for 802.11ac test. A white paper4 by Christopher D. Ziomek, ZTEC president and founder, and his colleague Matthew T. Hunter noted, “MIMO was introduced in WLAN protocols with the 802.11n standard as a way to increase data rates without requiring more RF bandwidth. The newest IEEE 802.11ac WLAN standard, which is still in draft format, will achieve up to 6.93 Gb/s using up to eight MIMO channels. Note that the legacy WLAN 802.11a/b/g protocols do not support MIMO. When transmitting a legacy protocol, an 802.11n/ac system with multiple antennas often uses STBC [space-time block codes] in a MISO [multiple-input single-output] configuration to improve channel integrity.”

As for the relevance of modular instruments, the ZTEC paper noted, “One challenge of MIMO instrumentation setup is synchronization of the multiple instruments. Modular instruments such as PXI or PXIe are ideally suited to MIMO due to their easily integrated instrument-on-a-card architectures. A PXI/PXIe RF test set can be configured with multiple VSAs, multiple VSGs, or both.” The paper presents as an example a modular PXIe test set with four synchronized ZT8651 VSAs for 4x MIMO transmitter testing.

According to the paper, “Triggers and time base clocks routed over the PXI/PXIe backplane enable time and phase synchronization between instruments for MIMO configurations.” The backplane triggers allow synchronized instruments to operate on the same WLAN packet or packets while the common time base enables phase synchronization between instruments, with the relative phase between instruments adjusted in software.

Leveraging PXIe Backplane Speed

Agilent Technologies also addresses 802.11ac with its modular instruments. According to an Agilent application note,5 “To validate MIMO transmitter performance, you should have a multichannel signal analyzer that can be used to demodulate the multistream waveforms and measure EVM and other physical layer parameters…. The test solution should be able to scale with the designs as they evolve, from single- and dual-channel 40-MHz to three- and four-channel 160-MHz MIMO designs.”

Jean Manuel Dassonville, modular solutions outbound manager at Agilent, said, “PXI modularity and performance fit well with 802.11ac technology because it requires scalable configurations, to support multiple-channel analysis, as well as synchronous, wide-bandwidth measurements that can be performed in a modular platform by sharing common resources such as LOs [local oscillators], downconverters, and signal-conditioning modules. The PXI PCI Express Gen 2 backplane enables high-speed transfers to the host controller for fast measurements,” adding that a PXI Express system can perform 802.11ac measurements on 80-MHz 256-QAM, 5.8-GHz signals in less than 200 ms. “Moreover,” he said, “PXI enables multichannel configurations in a small form factor, reducing the space needed on the bench.”

Dassonville said the same PXI-based test platform can be used for both design and automated test. “In the design (and debug) phase, the use model of the analyzer is mostly manual and interactive, and the designers need to perform a wide range of measurements to find the root cause of a DUT’s errors. The 89600 VSA software fits well with designers’ needs because it offers great insight into the DUT while enabling the interactive use model.”

As you move from debug to validation, Dassonville said, the analyzer will be used for automated tests, noting that the PXI architecture was designed to support test automation. He added that all Agilent PXI modules are provided with drivers, documentation, and examples to quickly develop test systems using software platforms including LabVIEW, MATLAB, Visual Studio, and VEE.

Courtesy of Agilent Technologies

Agilent’s specific hardware platform for MIMO design, validation, and test is based on a wideband MIMO PXI VSA, which is designed to deliver simultaneous wide-bandwidth analysis on up to four channels in an M9018A chassis having a 4U height (Figure 1). This PXI configuration provides analysis capabilities for up to 4×4 MIMO; it is suitable for 80 + 80-MHz SISO and 80-MHz or 160-MHz MIMO 802.11ac measurements.

The wideband MIMO PXI Signal Analyzer consists of Agilent’s four-channel M9362A-D01 Downconverter, the 12-bit M9202A Digitizer, the M9302A LO, the M9168C RF Attenuator, and the M9352A IF Amplifier/Attenuator Modules for one to four measurement channels. The M9202A IF digitizer’s 12-bit ADC offers typical residual EVM of -41 dB for 80-MHz-bandwidth signals, which exceeds the 802.11ac standard’s -32 dB EVM requirement.

Adding VSA Software

Use of Agilent’s MIMO VSA hardware with the company’s 89600 VSA software allows engineers to gain greater insight into the next-generation 802.11ac WLAN chips and devices, regardless of the 802.11ac format implemented, Dassonville said. The software offers the following:

- Support of duplicate legacy, mixed-mode, HT-duplicate, and VHT (very high throughput) formats.

- Support of all signal bandwidths, including 20, 40, and 80 MHz and 160 MHz in both contiguous and noncontiguous modes.

- Support of all 802.11ac modulation formats, from BPSK up to 256-QAM, with the capability to measure EVM and I/Q parameters and view the constellation of multiple spatial streams at once.

- Display of the contents of the L-SIG, HT-SIG, and VHT-SIG fields while providing CCDF, power vs. time, and time-gated measurements.

- Analysis of EVM by symbol, carrier, or burst and measurement of I/Q parameters, center frequency, bandwidth, power, ACPR, and demodulation to bit level.

Manufacturing Test Focus

Aeroflex is focusing on the manufacturing test of 802.11ac chipsets, components like power amplifiers, and end-user products, according to Pi Huang, product manager of modular RF/wireless test equipment at the company. The key challenges in manufacturing test, he said, stem from 802.11ac’s wider bandwidth, higher frequency, and increased modulation density from 64 QAM for 802.11n to 256 QAM for 802.11ac.

With respect to MIMO testing, he said, “MIMO testing imposes quite different requirements for R&D labs than for manufacturers.” R&D engineers, he said, “like to test what I would call true MIMO, so you would use multiple PXI modules to simulate signal generation or signal capture.”

At Aeroflex, Huang said, “We primarily focus on the manufacturing environment. In manufacturing you have already done all the device verification.” At that point, he added, “The design is fixed: there is no need to prove the design and the algorithms. The goal is to make sure the manufacturing quality is good and to support calibration. It is not very economical to use multiple signal generators and multiple digitizers in order to test, say, just one DUT with multiple spatial streams. So what people tend to do is test each RF stream sequentially.

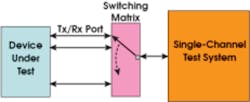

Courtesy of Aeroflex

“If you have a combiner sitting between the DUT and the test equipment (Figure 2), then it will just switch sequentially, say for a 4×4 MIMO switch, from path one to path four,” he continued. Such an approach, he said, offers better utilization of the test equipment and is a lot more economical.

One key factor for manufacturing test is speed, Huang said. Aeroflex’s 3000 Series PXI instruments can perform error vector measurements on 802.11ac signals, analyzing 16 symbols in about 24 ms (including capture and transfer as well as analysis) for an 80-MHz channel bandwidth.6

Also important to manufacturers, he said, is protection of capital investment. He noted that the advent of 802.11ac is making obsolete test equipment that can handle only the 2.4-GHz frequencies and 20- or 40-MHz channel bandwidths of previous generations of 802.11.

As manufacturers upgrade, he said, “They also are thinking, ‘How long can I utilize this equipment? I don’t want to spend [a lot of money] this year on ac and next year spend another huge amount on something else.’ So ideally they would like to have a software-defined platform,” one with hardware that achieves adequate bandwidth and frequency performance yet allows customers to enable software options.

Next Up: 60 GHz

As product developers and manufacturers and test vendors settle on strategies for 802.11ac, they will need to keep up with what is next on the horizon—the proposed 802.11ad, or WiGig, standard. According to the Wireless Gigabit Alliance, “The WiGig specification is based on the existing IEEE 802.11 standard, which is at the core of hundreds of millions of Wi-Fi products deployed worldwide. The specification includes native support for Wi-Fi over 60 GHz; new devices with tri-band radios will be able to seamlessly integrate into existing 2.4-GHz and 5-GHz Wi-Fi networks.”7

The 60-GHz frequency of the WiGig spec obviously will require test equipment with capabilities beyond what is required to test 5-GHz 802.11ac devices. But WiGig will be a short-range technology for in-room cable-replacement applications (the 60-GHz signals won’t penetrate walls), so it will complement, rather than replace, 802.11ac. Accordingly, software-defined modular test equipment that can handle the frequencies, bandwidths, and modulation schemes of 802.11ac should be sufficiently flexible to prove to be a safe investment.

References

1. Wi-Fi Chipsets: Is 802.11ac The New Black? Publication #IN1104996SI, NPD In-Stat, February 2012.

2. Hung, M., Market Trends: Future Platforms for Wi-Fi Growth, 2011-2015, ID Number G00213872, Gartner Research, June 29, 2011.

3. Hall, D., “The Next Evolution of Wireless LAN,” Instrumentation Newsletter, National Instruments, Oct. 13, 2011.

4. Ziomek, C. D. and Hunter, M. T., “MIMO RFIC Test Architectures,” ZConnect Quarterly, ZTEC Instruments, Q2 2012.

5. Accelerate Development of Next-Generation 802.11ac Wireless LAN Transmitters—Overview, Application Note, Agilent Technologies, 2012.

6. Huang, P., IEEE 802.11ac: Technical Overview and Challenges for Manufacturing Test, Aeroflex, February 2012.

7. Defining the Future of Multi-Gigabit Wireless Communications, Wireless Gigabit Alliance, July 2010.