Vector Signal Generators

The MG3710A has an ACLR of -71 dBc. SSB phase-noise performance is <-131 dBc/Hz (typical). The MG3710A also provides wide vector modulation bandwidth of 120 MHz that can be extended to 160 MHz using an external IQ input; absolute level accuracy is ±0.5 dB. A high-power output of +23 dBm eliminates the need for an external amplifier while reducing the risk of damage to the DUT. Fast switching speed of <600 µs makes the MG3710A suitable for production-test environments. The 4-GB memory per RF output allows multiple waveform data to be loaded for reduced reload and measurement times.

Pre-installed waveform patterns help engineers of various experience levels in testing to major standards. In addition, any pattern can be generated using the company’s IQproducer Software to output new RF test signals. From $25,200.

Millimeter-Wave Signal Analyzer

The EXA’s sensitivity (<–140 dBm/Hz across the V-band with the company’s smart harmonic mixers) enables accurate measurement of spurs and harmonics. Along with its phase-noise performance (-106 dBc/Hz typical at 10 kHz offset, 1-GHz carrier), the EXA is able to meet regulations and test requirements for millimeter-wave device design and performance verification. The EXA is a member of the Agilent X-Series signal analyzers, with frequency coverage from 10 Hz to 44 GHz. The X-Series spans instruments, measurements, and software, including more than 25 measurement applications that cover cellular communications, wireless connectivity, digital video, and other purposes. From $42,000 for the 32-GHz option (N9010A-532) to $60,000 for the 44-GHz option (N9010A-544); external mixing upgrade: $2,805 and available on 32- and 44-GHz EXA.

High-Speed Memory Test System

The T5511 also features a hardware CRC code generator function, necessary for DDR4-SDRAM and GDDR5-SDRAM device test. The dedicated hardware generates CRC codes automatically, reducing the burden on the operator and making it simpler to create test programs. Additionally, the T5511 runs the vendor’s Future Suite tester OS, letting operators use the library of program data created for T55xx Series Test Systems.

System configurations range from 384 pins for R&D use through to a maximum of 6,144 pins for volume production. The T5511’s lab-to-fab flexible configurability allows customers to hold capital investment to a minimum while achieving maximum test efficiency. Target devices include DDR4-SDRAM, GDDR5-SDRAM; parallel test capacity extends to 256 (x8 I/O); and maximum test speed is 4 GHz/8 Gb/s.

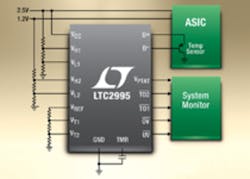

Temperature Monitor

The LTC2995’s accuracy, configurability, and code-free operation cater to a variety of applications including system thermal control, energy harvesting, and environmental monitoring. Users can choose to measure local temperature, remote temperature, or both in alternation while two temperature output pins can be configured to any combination of undertemperature and/or overtemperature alerts. Temperature conversions are updated every 3.5 ms to provide systems with sufficient time to react to alerts.

Networking Test Tools

UNH-IOL Test Tools help member and nonmember companies of The University of New Hampshire InterOperability Laboratory (UNH-IOL) Consortium speed time to market by pre-testing products in-house. Supplemental to the services offered through membership in the UNH-IOL’s Consortium, the UNH-IOL Test Tool line serves as an additional resource to companies facing aggressive product launch timelines. By utilizing UNH-IOL Test Tools in their own laboratories, companies’ testing, quality-assurance, and development teams have the flexibility to perform testing in accordance with their product development cycles. Internal pre-testing also allows companies to identify and resolve issues and improve products/designs in advance of sending their products to the UNH-IOL for official testing or certification.

Bowl Feed Handler Option

3-D X-Ray Software

The OptiCon XI-Pilot 3.0 X-Ray Inspection System Software, running on the OptiCon X-Line 3-D X-Ray Inspection System, enables a higher image recording speed at increased sensitivity. Additionally, new features compensate for PCB warpage and support automatic stability control of the image sequence.

The software detects and corrects for PCB slag during the inspection process. The result is a true-to-height solder-layer reconstruction that supports high-quality evaluation of solder joints. Based on PCB condition, it is possible to select whether the entire assembly or each partial circuit of a certain type should be compensated. For PCB warpage determination, a laser triangulation sensor can be applied. It also is possible to compensate for PCB slag directly in the recorded images using software algorithms.

An X-ray inspection system image sequence generally consists of a source for X-ray emission and a detector to convert radiation weakened by the UUT into visible light. Natural ageing processes of these components change grey values in the X-ray images, which may lead to faults in algorithmic evaluation of solder joints. According to the company, the software automatically detects changes in the X-ray image chain and recalibrates as required, guaranteeing constant image quality and measurement values in the system during the inspection process.