Whole-Body Vibration Testing Using LXI Devices

Whole-body vibration (WBV) is a common occupational risk for workers using heavy construction machinery such as bulldozers, tractors, and forklifts as well as transportation drivers of buses, trains, helicopters, and trucks. Regular exposure to excessive vibration transmitted into the body while seated, standing, or lying down can lead to a number of physical health effects to the body’s spinal, nervous, digestive, reproductive, and visual systems. Industries such as construction, transportation, manufacturing, and agriculture need to regularly measure and limit exposure of WBV to their workers.

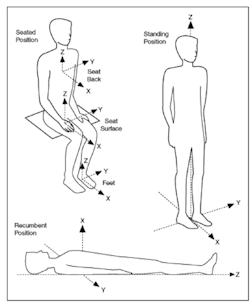

ISO 2631-1 is an international standard titled Mechanical vibration and shock – Evaluation of human exposure to whole-body vibration.1 According to this standard, vibration needs to be measured on the surface between the body and the surface along three orthogonal axes (Figure 1).

Figure 1. Measurement Axes of WBV in the Human Body

Source: ISO 2631-1

Measurement Approach

Vibration measurements are complex and may contain several frequencies that occur in different directions that change over time. According to the ISO standard, WBV on a person in the seated position needs to be measured at all the supporting surfaces (seat, back, and feet) along the three axes shown in Figure 1.

Since most WBV measurements must be taken in remote workplace environments, Ethernet-based LXI devices can facilitate the performance of vibration testing. The LXI standard offers low-cost, open-standard LAN (Ethernet) as the system backbone and ensures software and hardware compatibility of LXI-compliant test and measurement equipment.

An example of a device that can accurately measure WBV is Data Translation’s DT8837 LXI instrument module for sound and vibration (Figure 2). Vibration data is collected using a multi-axis accelerometer sensor connected to the DT8837. The TCP/IP Ethernet operation allows measurements to be monitored locally using a laptop or at another remote site in real time. Up to 16 instrument modules may be stacked for parallel operation of up to 64 accelerometer or voltage inputs. These modules are synchronized via LXI’s Wired Trigger Bus and can be externally triggered in various ways.

Figure 2. DT8837 with LXI Web Interface

Courtesy of Data Translation

Monitoring devices in difficult or harmful conditions is challenging with remote applications. The capability to share information or device controls with colleagues in any part of the world is fast becoming a necessity.

This remote accessibility is provided through LXI discovery utilities and an instrument web interface. For example, Data Translation’s Eureka Discovery Utility helps locate all LXI instruments available on a network and provides the instrument’s IP address, manufacturer, model number, serial number, and version of the firmware. This utility can be used to configure the Windows firewall settings and update the firmware for the LXI instrument. The built-in web interface allows you to verify instrument operation and perform basic functions from a remote location with a W3C-compliant browser without additional software. Using the LXI web interface, you can configure the instrument, control and measure input signals, and save results to disk.

An IVI-COM driver is another valuable software component required for LXI conformance. This driver provides a COM-based programming interface to access instrument functions. The IVI-COM driver works in any development environment that supports COM programming, including MathWorks MATLAB, C#, VB.NET, Visual Basic, Agilent VEE Pro, and National Instruments’ LabVIEW.

Basic Evaluation Method

The ISO 2631-1 standard defines a basic evaluation method for determining weighted rms acceleration to evaluate the impact of WBV. The following equation is used to calculate the weighted rms acceleration:

where: aw(t) = the weighted acceleration as a function of time measured in m/s2

T = the duration of the measurement in seconds

The weighted rms acceleration needs to be determined for each axis of vibration on the surface that supports the person.

For certain types of vibrations, particularly those with occasional shocks, the basic method may not be sufficient. In those cases, the ISO standard provides alternative methods such as the running rms or fourth-power vibration dose value.

Assessment of the Level of Vibration

The longer a person is exposed to a vibrating environment, the greater the risk of health effects. However, it generally takes years for health issues due to WBV to occur. To avoid long-term health risks associated with WBV, the continued exposure to vibration on the human body needs to be accurately measured and analyzed.

There also are some online tools available to calculate the risk of WBV. One such tool can be downloaded from the Health and Safety Executive (HSE) website.2 The HSE defines the exposure action value of 0.5 m/s2 as the acceptable average amount of daily exposure to WBV, above which action must be taken to reduce risk. The exposure limit value is the maximum amount of vibration an employee may be exposed to on a single day and is set by the HSE at 1.15 m/s2.

The ISO standard defines the comfort reactions to vibration environments as shown in Table 1.

Table 1. Levels of Comfort for Vibration Environments

Source: ISO 2631-1

Summary

WBV is a workplace health and safety concern for drivers or operators of vehicles or machinery exposed to excessive vibration transmitted to the whole body. WBV causes discomfort and long-term health risks. LXI instruments provide a LAN-based, off-the-shelf solution ideally suited to perform vibration measurements in remote workplace environments. Measured data can be transferred in real time via Ethernet for further analysis, and the level of health or comfort risk associated with the vibration exposure can be quickly determined.

References

1. ISO 2361-1, Mechanical vibration and shock – Evaluation of human exposure to whole-body vibration.

2. “Whole Body Vibration Calculator,” Health and Safety Executive, United Kingdom.

About the Author

Ellen Harpin works with the Product Marketing Group at Data Translation. She has been with the company since 1983, holding various management positions throughout her career in sales, marketing, finance, engineering, and manufacturing. Ms. Harpin has a B.S. in business management and attended the executive management program at the Stanford Graduate School of Business.