The use of switching systems to route instrumentation and stimulus signals to appropriate test points on a unit under test (UUT) has a very crucial role to play in most electronics test systems. The sharing of test resources, connection of calibration references, load management, and many other functions are all managed by the switching system. The switching system acts as the interface between the UUT and the test equipment.

The accuracy and repeatability of a test system are controlled to a great degree by the switching platform selected for the application. Choices can be based on platform, budget, size, and application.

Pickering Interfaces has been involved in the development of complete switching systems since its products were introduced in 1988. Using the knowledge base of reed relays offered by its sister company, Pickering Electronics, Pickering Interfaces has developed a range of switching systems based around a proprietary platform that provided GPIB or RS-232 control of the relays.

Even at that time, there was a demand for switching systems based on open modular standards. As a result, Pickering introduced switching products based on both the VXI and the PXI standards.

The PXI standard, despite doubts expressed by some, has proven to be an excellent basis for switching products as well as instrumentation. Although the PXI form factor is small, the development costs are relatively low once the initial PXI entry barriers have been crossed. The speed of product development can be high, enabling a large variety of standard and custom switching solutions to be made available in response to user demand.

The PXI standard is mature and has been widely adopted in the test industry. While it offers a fast communications interface to support applications requiring the exchange of the large blocks of data that may be needed for analysis by the system controller, it also imposes mechanical and power restrictions on the modules. Not all users want instrumentation or switching products to be extensions of the PC’s PCI bus or for the data analysis to be performed in the PC rather than processing in the instrument. Although it has been hugely successful, PXI has not always displaced the majority of rack or bench instruments historically based largely, but not entirely, on GPIB interfaces.

GPIB instruments have more recently had their control interfaces either supplemented or replaced by the much more recently standardized LAN/Ethernet connection, and the de facto standard for control via the Ethernet interface is LXI. Ethernet is ubiquitous on system controllers, and the connection cables are easily managed and have a latching mechanism and virtually no restrictions on distance or the number of instruments supported. The LXI standard enforces compliant instruments to implement the Ethernet control in a standardized way, eliminating the concerns about conflicts on the Ethernet connection that could arise on proprietary implementations.

Standardization of LAN connections for instrumentation was a major leap forward following the introduction of the LXI standard in 2005. The adoption of LXI has been rapid; the value of LXI-enabled products shipped is, for example, much higher than the value of PXI product. There now are approximately 2,000 LXI- compliant products available, a number that continues to grow. Like PXI, the standard is mature and stable, having reached version 1.4 in 2011, and LXI devices conforming to the first version of the standard still interoperate with the devices conforming to the latest version.

Comparison of LXI

There has been speculation that PXI and LXI are competing standards, a view that Pickering does not share. They are sufficiently different that there often will be clear cases where one is better for a particular solution than another.

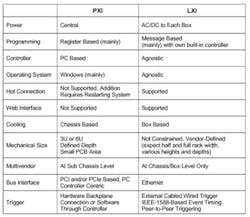

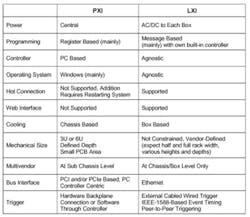

Table 1 illustrates examples of these differences. The relevance of any one factor in this table is dependent on what product the user or vendor wants to create.

Table 1. Comparison of LXI and PXI Architectures

LXI instruments are largely platform agnostic whereas PXI is very dependent on the PC architecture (and in many implementations, Windows). LXI devices do not have many mechanical or electrical constraints, but PXI products must conform to the PXI standard to benefit from the multivendor chassis platform. They also can have quite different data speed drivers.

Although PXI has faster connection speeds, it relies on processing data in the controlling PC—so it inherently needs a high-speed interconnect to perform data-processing functions. An LXI system might be expected to process data within the LXI devices and simply report the results, but it also can dump blocks of data for controller processing.

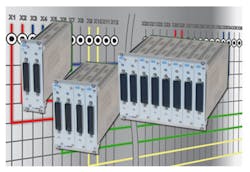

The PXI standard must permit products from different vendors to coexist in a chassis; otherwise as a standard, it fails to meet the market expectation and the objectives stated in the standard. That means that a chassis such as the Model 40-923A (Figure 1) and the software infrastructure have to interoperate with potentially many different types of instrumentation or switching modules in the same chassis. The chassis design must meet the defined minimum requirements set out in the PXI standard.

Figure 1. 40-923A with PXI Modules

The chassis choice can get a little more complex since the PXI standard has evolved into two distinct types of backplane control interfaces, PCI and PCIe, which are not interchangeable. PXI chassis provide slots that support PCI-based modules. PXIe chassis feature slots exclusively for modules that are PCIe-based or support both PCIe- and PC-based modules (but not at the same time) and slots for PCI-based modules. The increased complexity of PXIe chassis means they are more expensive to manufacture when they support both PCIe and PCI interfaces.

As a result, you must carefully choose a chassis that ensures all slots can be used, but otherwise interchangeability is largely assured by compliance to the standard. The vast majority of modules have PCI interfaces rather than PCIe interferences.

Since there are no chassis constraints to concern LXI users, simply complying with the minimum requirements set out in the standard is enough unless specific support is needed for optional extended features such as IEEE 1588 timing.

Applying to Switching

For switching, speed differences are of little consequence because, in practice, the speed of change is constrained by mechanical components (relays)—even solid-state switching does not need the multigigabit speeds of PXIe. The mechanical and electrical constraints of PXI can influence what can be cost-effectively supported in PXI. But on the other hand, the cost overheads of an LXI device can limit the minimum functionality that can be cost-effective.

As ever, one standard does not fit all, and LXI offers the greatest freedom of design while PXI offers a means to integrate small modules into an open standard chassis. Unsurprisingly, that means both have their place, and both standards can claim circumstances under which they might perform better than the other.

Pickering Interfaces has a range of PXI switching products that have been developed in the last 15 years. A significant number of users have found that PXI is the answer to their switching needs, and indeed, it forms the majority of our switching business. These users typically are employing a mix of instrumentation and diverse switching functions.

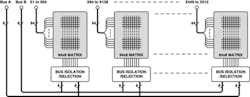

There is a clear distinction based on size. Where, for example, a large structured matrix is required, such as the Model 60-55X shown in Figure 2, then LXI often will be the better choice. PXI can be used to implement these large systems, but the chassis, cable interconnect, and software complication of implementing a large switching function over many modules increase the system cost, decrease its performance, and add complexity to the system design and programming time.

Figure 2. 60-55X Functional Diagram

In PXI, some of these issues can be partly addressed by using modules which extend over more than one slot, an example being the Pickering Interfaces BRIC introduced in 2002 (Figure 3). These products integrate the switching system over two, four, or eight PXI slots using only one connection to the backplane and then use their own backplane to provide connectivity between the subassemblies in the BRIC. That reduces cabling and interfacing costs that otherwise would be incurred and makes a PXI solution much more competitive, although still not as competitive as can be created in LXI platforms with even larger switching systems.

Figure 3. BRIC Switch Module

Pickering Interfaces’ PXI modules do not have to be confined to PXI chassis. For users with diverse switching needs, PXI designs may be perfect, but users do not necessarily want to spread their computer PCI bus over external chassis. They may need a longer distance between the controller and the instruments or simply want to get a more web-like feel to the system for remote access or to make changes without powering down the entire system. For these applications, Pickering Interfaces introduced LXI chassis that support Pickering PXI modules.

The restriction to Pickering Interfaces modules is a software issue rather than a hardware issue—the LXI chassis has an embedded Linux-based controller that requires access to source code for the modules supported. The same controller gives the user a barrier between the PXI modules and the controller that provides all the features of Ethernet connectivity, including web-based management of the PXI switching modules.

Modularity is not disallowed by the LXI standard—it is simply not required—so vendors also can create proprietary modular formats to solve particular problems. The recently introduced 65-110 (Figure 4) is an example of this. It solves user requirement for a very broadband (usable to 500 MHz) matrix with low crosstalk. The chassis provides a proprietary cableless interconnect between modules with each plug-in module having a much greater footprint than PXI.

Figure 4. 65-110 LXI Scalable and Modular Matrix

Summary

There is no best platform for switching—the LXI and PXI standards bring different advantages and disadvantages to users depending on what they are trying to do. In this respect, instruments also are not that much different. There always are examples of where PXI and LXI implementations will have different compromises on cost, performance, and size. Vendor-designed enclosures usually will convey performance advantages to LXI solutions; a modular chassis system can offer advantages in cost and size for diverse systems. LXI solutions can be modular.

There is a wide spectrum of possibilities open to users. For companies that embrace both the LXI and PXI standards for their core products, it is very much a question of letting the user decide the most appropriate solution for the application rather than forcing a particular platform on the user.

That is the nature of standards; they use a set of assumptions that has consequences when products are created that use them. For Pickering Interfaces, those consequences to switching systems create different ways of tackling problems which depend on component size, switch system size, and switching system diversity.

About the Author

David Owen is the business development manager for Pickering Interfaces. Over the last 25 years, he has held key engineering, product management, and strategic marketing positions with Marconi Instruments, then IFR (now part of Aeroflex). Owen was the named innovator of more than 10 patents in the field of RF signal generation and analysis and has written many application and technical support notes for signal management and switching. [email protected]