Test engineers seek equipment commonality

Autotestcon convenes Nov. 2 in National Harbor, MD, and will give test-equipment makers an opportunity to demonstrate how they are supporting trends that have evolved since last year’s event in St. Louis. Affordability remains a key concern, but related issues cited by industry participants include commonality, the rise of modular instruments, the need for long-term support, the need to get test systems close to the equipment under test, and the capability to adapt low-cost consumer technologies to MIL/aero applications.

Steve Sargeant, CEO, Marvin Test Solutions, commented on several of these trends. First is consolidation, or commonality, of test solutions. “Whether it’s on the flightline or at I-level or depot level, test engineers and maintainers are looking for solutions that are applicable to a range of aircraft, weapons systems, avionics, etc. We see this in the requests for proposals being generated by the services and also by the major acquisition (M-A) manufacturers/suppliers.”

He added that users want these systems to support not only next-generation test needs, but also existing test needs—they require robust tools and capabilities for migrating existing test program sets (TPSs). “It’s an accepted fact that the life cycles for many M-A systems and products continue to stretch out, requiring test systems/solutions that can effectively bridge the gap between legacy and next-generation test needs,” he said.

A second trend Sargeant identified is the move toward modular instruments. “We continue to see the adoption of test systems based on modular platforms—particularly PXI,” he said. “Ongoing advancement in instrumentation is enabling the creation of test systems that can provide compact, cost-effective performance solutions for flightline, depot, and manufacturing test in the areas of digital, mixed-signal, RF, and even electromagnetic warfare. Virtually all of our test platforms for I-level, depot, and manufacturing are based on PXI today. We are even seeing RFQs specifying PXI as the platform of choice for next-generation test solutions.”

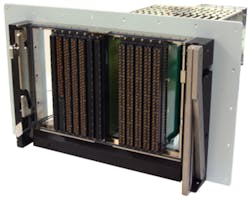

Courtesy of Marvin Test Solutions

One product Marvin Test will be exhibiting is the MTS-2xx platform—an ultrarugged, PXI-based test system supporting I-level and flightline test and deployed in more than 20 countries supporting multiple aircraft (Figure 1). “The platform addresses advanced test needs for avionics and armament test using the open architecture of PXI,” Sargeant said. “It is used as the baseline platform for the MTS-206 Maverick Field Test Set, MTS-209 Common Armament Test Set, MTS-235 F-35 AME Test Set, AN/TSM-205B Hellfire System Test Set, and the USAF’s PATS-70 test system for the A-10.”

Modular rivals box performance

Keysight Technologies also is seeing a trend in which the DoD is moving toward modular architectures. The performance of new modular products rivals that of traditional dedicated instrument box solutions, said Marty Leeke, market development manager. Modular architectures, he said, allow ATE developers to enhance the capability of their ATE without redesigning an entire rack of equipment. In addition, he said, the reduced size allows commonality among support organizations (field, depot, and intermediate levels).

Leeke also said the MIL/aero community faces continued pressures to adapt their technical and business practices toward more fixed firm-cost contracts. “Affordability is still a high-priority need,” he said. “To that end, Keysight remains focused on delivering hardware, software, and solutions that are aimed at lowering the cost of test and ownership.” Relevant to the strategy are new services like multivendor calibration and extended service plans as well as new products that are available in benchtop, modular, and handheld form factors. Further, Leeke said, new software can simulate designs and minimize the unforeseen margin and other design errors in manufacturing to increase yields and reliability.

According to Bob Stasonis, sales and marketing director at Pickering Interfaces, “Clearly, the acceptance of modular standards other than VXI is moving forward. But as government spending tightens, budgets are being scrutinized. So the justification process for MIL/aero test is starting to resemble that of commercial applications. As our products are COTS solutions and sold to a broader market, they tend to be lower cost than custom designs.”

Stasonis said Pickering strives to meet customer needs. “We don’t think that our users should have to buy too much switching just because there is little choice,” he said. “That is why we have more than 1,000 modules in PXI alone. We work closely with our customers to define exactly what is needed.”

Stasonis added, “The other area where we shine is in our policy on long-term support. We usually can commit to manufacturing replacement modules for 10 years, 15 years, and even longer. We still sell switching we designed in the 1980s. If we can’t manufacture modules due to component obsolescence, we will endeavor to design a new module that is form/fit/function to the original. MIL/aero companies and all branches of the military appreciate that as many programs remain active for 20 years or more.”

Also commenting on affordability was Tom Sarfi, director product management, VTI Instruments. “With defense budgets decreasing, many of our customers are looking to preserve their existing test-system designs since migration to new architectures can be quite costly,” he said. “Unless there are motivating factors or opportunities to introduce new technology, the shortest path to maintaining a steady production flow, without interruption and at the lowest cost, is to continue to use what has worked in the past. To that end, we continue to invest in our legacy products to keep them viable and in production in order to keep these customers up and running.”

Sarfi continued, “In the aerospace market, we have been seeing a drive to move test instrumentation closer to the unit under test. For example, jet-engine manufacturers who used to keep the test instruments in a controlled environment are moving the instrumentation as close to the engine as possible to limit the length of cabling carrying low-level analog signals. Our newer data-acquisition products have been designed to operate in these harsh environments.”

Leveraging consumer tech

Courtesy of Astronics Test Systems

Another trend is the MIL/aero community taking advantage of improvements coming from consumer technology. “Improvements in the consumer space are now driving the aerospace and defense (A&D) test market,” said Kevin Leduc, senior sales and product line manager, Astronics Test Systems. “We now expect to have a small powerful smartphone in the palm of our hand. These improvements are making their way into the A&D test space in the form of smaller instrument and system form factors.” He cited as an example the company’s PXIe-2681 counter (Figure 2), which in a smaller form factor provides capability exceeding that of the company’s VXI 2461-CD counter.

Also coming from the consumer space are improved man-machine interfaces and ubiquitous computing power. Leveraging interface technology, Leduc said, “ATS’ TestCue software provides a visual representation of system and test status.” As for ubiquitous computing power, he said that ATS’ T940 digital test subsystem uses FPGAs to be much more agile and flexible than previous digital test systems.

Leduc also cited a desire for platform and supplier independence. “Customers want to mix and match the best technologies from multiple platforms (VXI, PXI, and LXI) and multiple suppliers,” he said. “Our Freedom2 test platform provides a flexible core that makes it easy to combine industry-leading technologies from ATS and our partners into a test system that is optimized for the particular user.”

Synthetic instrumentation

According to Abhay Samant, RF section manager at National Instruments, test systems must evolve to address issues such as instrumentation obsolescence, increasing complexity of RF test, and the need to reduce the cost of test. “Fundamental to this evolution is the role of synthetic or software-designed instrumentation,” Samant said. “The inclusion of user-programmable FPGA technology into instrumentation such as oscilloscopes, digitizers, vector signal analyzers, and vector signal transceivers, in concert with the productivity gains of system design software that simplifies the programming of FPGAs, has given MIL/aero test engineers a cost-effective solution for combating these challenges.”

Samant added, “NI has played a key role in building a foundation for innovation by continually delivering a broad and high-performance PXI portfolio and LabVIEW system design software to meet the I/O point and performance needs of customer applications.” NI offers several products, he said, that “… provide MIL/aero system design and test engineers a common platform for building both advanced test and support systems, thus improving mission effectiveness.”

With software-designed instrumentation, Samant said, engineers can access embedded FPGAs through LabVIEW—they don’t need a deep understanding of design tools such as VHDL or Verilog. “This advantage enables engineers to use an off-the-shelf instrument that can be customized to meet their needs today and in the future,” he said. “These high-performance instruments offer a compact form factor that makes them efficient for in-situ testing of LRUs. This, coupled with the power of state-of-the-art Intel processors and access to the FPGA through LabVIEW system design software, allows users to provide effective diagnostic tools to the test engineers so that they can debug the issues and reduce system downtime and to shorten time to market, whether it is a production test use-case or a depot-level maintenance test.”

Long-term support

Herman vanEijkelenburg, director of marketing at Pacific Power Source, echoed Stasonis of Pickering Interfaces in emphasizing the need for long-term support in MIL/aero applications. “Existing test stands and TPSs have to be supported for a much longer time frame than originally intended,” he said. “This requires long-term product and service support by test and measurement vendors. Pacific Power Source continues to support the ATE market with parts, service, and legacy product manufacturing in addition to new technology products to help drive down cost.”

At Autotestcon, vanEijkelenburg said, the company will demonstrate precision programmable AC power sources for field and depot ATE test systems, including the Model 308AMX three-phase linear, low-noise, low-distortion AC power source (Figure 3). The products, he said, are compact and efficient and offer a wide range of power levels, yet all share the same controller interface and programming syntax so they can be scaled across a wide array of requirements without the need to change software.

Courtesy of Pacific Power Source

Courtesy of JTAG Technologies

Peter van den Eijnden, managing director at JTAG Technologies, said the company will demonstrate its mixed-signal JTAG tester, the JT 5705 (Figure 4). “JT 5705/USB offers a unique combination of JTAG TAP controller (tester) interfaces plus digital and analog I/O in a compact desktop package,” he said. “The JT 5705/FXT has the same features in a format that can easily be integrated in fixtures. All voltages are fully programmable. The JT 5705 is ideal for hardware validation or small-scale production test. Based on the JT 5705, a standalone station that can test and measure both analog and digital signals can easily be built.”

He added, “We also will show our other boundary-scan controllers and the software support we have available for Teradyne’s Di-050 and HSSub hardware. For our high-end JT 37×7 controllers, we will show our pull-though QuadPod solutions for mass interface receiver systems from Virginia Panel and MAC Panel, respectively.”

Autotestcon product expectations

For its part, Virginia Panel will showcase its new i2 MX connector, which, the company said, builds upon the success of the popular i2 Micro iCon, offering a configurable connector in the same 0.8-inch footprint. Combined with its slimmer, metal engagement knob and its oblong cable exit, the i2 MX provides maximum cable bundle clearance and improved stackability.

Courtesy of Keysight Technologies

In addition to showing its MTS-2xx platform, Marvin Test Solutions will highlight its MTS-3060 multifunction flightline tester, the GENASYS PXI-based platform for functional test, ATEasy software, and the GX5296 digital subsystem.

Keysight will demonstrate its new FieldFox 50-GHz handheld analyzer (Figure 5) as well as a variety of PXI and AXIe instruments—including a measurement solution intended for military radio producers.

VTI will show its signal switching and I/O products, which, Sarfi said, are well-positioned for the MIL/aero ATE marketplace and have been part of the VDATS, eCASS (Figure 6), RT-CASS, and the production NGATS test stations. The company also will introduce three new ruggedized data acquisition products capable of measuring temperature, dynamic strain, and charge inputs to a high degree of accuracy and synchronization within a harsh environment.

Courtesy of VTI Instruments

NI will highlight a variety of products, including a controller for its FlexRIO platform (Figure 7), a 26.5-GHz VSA and spectrum analyzer, a fast-switching RF signal generator, a high-speed serial instrument, an 18-slot PXI Express chassis with PCIe 3.0 technology, and an eight-core Intel Xeon-based PXI Express embedded controller.

Courtesy of National Instruments

Pickering Interfaces will show its continually expanding offerings in three platforms—PXI, PCI, and LXI, including high-density, higher current switching modules, based on demands from MIL/aero manufacturers. In addition, Stasonis said the company will highlight its partnership with OPAL-RT in the area of fault insertion for HILS applications. He described the company’s new Modular Break Out Box, or Modular BOB (Figure 8), as a low-cost system to provide access to all UUT signals during test-program development. Also, the company will highlight its eBIRST comprehensive switching test tool.

Courtesy of Pickering Interfaces

Universal Switching can be expected to highlight its System S24530A multilevel digital matrix for routing RS-530 type signals (or similar multilevel bidirectional digital signals) with up to 24×24 I/Os in one unit. Applications include ground stations, telecom equipment, uplink or downlink control signals, communications centers, and satellite installations.

Wireless Telecom Group will likely exhibit its RF peak power meters and RF/analog AWGN noise generators, representing its Boonton and Noisecom brands, including the Boonton 55 Series USB peak power sensor. The 55 Series is suitable for R&D, manufacturing, or field use for wireless telecom as well as radar applications.

And finally, ADLINK can be expected to exhibit its new PCIe-PXIe-8638 high-performance PXI Express remote controller, enabling remote control of any PXI Express system directly via PC. Fully software- and driver-transparent bandwidth up to 4 GB/s is available through PCIe Gen 2 x8 link capability.

The dozen companies mentioned in this article have indicated to us their plans for Autotestcon. Yet another five dozen or so are planning to participate. Visit our Autotestcon page for more details that have emerged since this article went to print.

Technical program

The link above also will provide you with up-to-date information on the tutorials, keynote addresses, panels, and technical sessions that will complement the exhibits.

Of note is a session titled “ATE Lessons Learned” chaired by Joe Cuccaro of the U.S. Army. David Holmes of Raytheon will note that in many organizations, development of Special Test Equipment (STE) is an afterthought, with inexperienced engineers assigned to the task and shortcuts taken. But, such an approach, he will note, can actually increase the life-cycle cost of the STE.

Christopher Phillips, Jesse Sandoval, Todd Burton, and Derrick Jensen of Northrop Grumman Technical Services will note that the factory, depot, and field are all different environments, creating a scenario where the unit under test is tested under variable conditions. Often, a line-replaceable unit (LRU) swapped out in the field doesn’t exhibit a failure when returned to the depot. The LRU may then cycle through the system several times until the depot detects an “environment agnostic” hard failure. What’s needed, they will say, is factory- or depot-quality testing in the field.

Other sessions will cover software, prognostics and health monitoring, specialty ATE, software test, novel test and diagnostic techniques, and technology insertion in today’s instrumentation. A session titled “Improving the Accuracy and Reliability of Test Results” will address topics ranging from time-inverted ADCs (by Charna Parkey and Wasfy Mikhael of the University of Central Florida) to detection of soft errors in redundant systems (by Luis Bustamante and Hussain Al-Asaad of the University of California, Davis).

Yet another session will cover FPGAs in modern instrumentation. Papers in this session include “Embedded Synthetic Instruments for O-Level Test: Modular IO and FPGA Technology Provide Increased Flexibility and Decreased Cost of Test” by Robert Bauer of National Instruments, and “Reducing the Cost of Test for High-Speed Serial Buses with COTS FPGA Technology” by Christopher Nunn, also of NI.

The technical program will conclude with sessions including “Supportability Enhancement Topics” and “New Directions in Instrumentation Architectures.” Papers in this latter session include “Shelf Management for AXIe Applications” by Gary Hanson of Elma Electronic, “Introducing PXI Instrumentation Into An Existing VXI Based Tester” by Kevin Paton of Teradyne, “Multi-Channel Phase Coherent Measurements Using COTS Modular Instruments” by Alexander Dickson of Keysight Technologies, and “PXI-Based, High Performance, High Density Switching Architecture” by Michael Dewey and David Manor of Marvin Test Solutions.

For more information

- ADLINK Technology

- Astronics Test Systems

- JTAG Technologies

- Keysight Technologies

- Marvin Test Solutions

- National Instruments

- Pacific Power Source

- Pickering Interfaces

- Teradyne

- Universal Switching

- Virginia Panel

- VTI Instruments

*The original version of this article incorrectly pictured the CompactRIO controller. We apologize for the error.