Supporting the past, building the future

Engineers working on military and aerospace applications need to do more with less as they upgrade legacy ATE systems or acquire new ones while preserving their test-program-set (TPS) investment. Many products and techniques that can help them were the focus of Autotestcon 2015 last November in National Harbor, MD, and since the show’s conclusion, companies have continued to emphasize hardware and software for the MIL/aero industry.

Steve Fairbanks, senior director of marketing, Products and Instrumentation at Astronics, said, “With the reduced availability of federal funds to support defense systems, our customers are forced to rely on older technology and rely on it far past its initial design lifetime. These systems represent a logistical challenge with obsolescence and parts availability as well as retiring experts. The main concern we hear is customers wondering how to bring support systems forward in technology at the lowest possible cost. They’re interested not only in maintaining all of the original functionality, but also in evolving that technology forward to remain relevant as future capabilities arise.”

Mike Dewey, director of marketing at Marvin Test Solutions (MTS), said, “One of the primary issues we see is the ongoing requirement to address legacy test needs. More specifically, how can this be done cost effectively when there might be hundreds of existing TPSs that need to be supported or upgraded to work with new test platforms? The requirement to address both legacy and future test needs is driving the search for creative test solutions that are more efficient, flexible, and usable across multiple platforms and programs. These requirements are being seen from the flightline to the factory.”

And Herman vanEijkelenburg, director of marketing for Pacific Power Source, said, “An overriding theme fairly evident [at Autotestcon] was the need to support older ATE systems and platforms for a longer time than what was originally planned. This is driven by lack of funding for new programs due to sequestration and budget cuts. This is shifting increased focus from developing new test systems to upgrading and supporting existing aging testers. As a result, T&M equipment manufacturers are asked to support their products for long periods of time, far longer than would be the case for commercial test applications.”

Courtesy of Astronics

From night-vision goggles to jet engines

At Autotestcon, Astronics demonstrated a variety of products including test instruments, radio test sets, an engine test stand, and general-purpose depot and factory ATE including the Freedom 2 system. For example, Fairbanks said, the ATS 3000 Series of Radio Test Sets are deployed for field and depot testing of tactical military radios. “The Freedom 2 is a factory and depot-level test solution designed to be open, modular, and scalable to meet any demanding test requirement,” he said. “Based on a common core approach of critical hardware and software, the Freedom 2 can be easily customized for virtually any test application—from night vision goggles to jet engines.”

Fairbanks also said that Astronics is leveraging TPS capability and investments with the introduction of new products like the Astronics 2461 PXIe-based Frequency Time Interval Counter (FTIC). “We’ve collaborated with National Instruments to replace older VXIbus technology with the modern PXI-based instrumentation for tomorrow’s military systems,” he said. “The new Astronics 2461 FTIC streamlines military/aerospace test development with smaller, lighter, next-gen PXI technology.” This new product is modeled after the previous VXI-based version, the Astronics VXIbus 200-MHz Universal Counter. Designed for full TPS compatibility, this new FTIC will replace existing VXI-based FTICs in a newer PXI-based subsystem. Fairbanks added, “Customers can purchase the Astronics FTIC for PXI Express and future products expected to become available as a result of the collaboration, as well as support service, through the worldwide NI sales channel.”

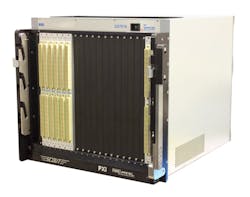

For its part, National Instruments highlighted a variety of new products and technologies designed for MIL/aero system design and test engineers in addition to the new FTIC. Ravichandran Raghavan, senior product manager for automated test systems, highlighted in particular a 26.5-GHz vector signal and spectrum analyzer, a fast-switching RF signal generator, an 18-slot PXI Express chassis, and the latest FlexRIO controller that features an embedded processor and Xilinx FPGA.

“The FlexRIO controller particularly resonated with Autotestcon attendees,” he said. “The controller delivers high-performance I/O, a powerful Xilinx FPGA, and an embedded processor in a form factor optimized for deployment.”

Courtesy of National Instruments

Raghavan said NI provides more than 600 PXI instruments ranging from DC to 26.5 GHz, “… and we sell nearly all of them into aerospace/defense applications.” He cited as an example the new PXIe-5668R 26.5-GHz vector signal analyzer, which includes a user-programmable Kintex-7 FPGA. Aerospace/defense engineers can target the instrument to be a best-in-class real-time spectrum analyzer with industry-leading 765-MHz bandwidth, he said, or implement a custom pulse-measurement capability to make the instrument a world-class radar test head. “The versatility of software-designed instruments like the PXIe-5668R provides a unique value to aero/defense engineers not only in meeting new technology demands, but also in emulating niche legacy instrument features for obsolescence management and TPS migration,” he concluded.

According to Dewey at MTS, products that drew particular interest at Autotestcon included the new GX5296 PXI digital subsystem which, he said, features the highest digital test capability in the industry as well as per-pin timing and PMU capability. “Also attracting attention was our GENASYS switching subsystem, the GX7016, which combines the flexibility of the PXI architecture with a high-density, hybrid pin switching architecture, which offers more than 4,000 UUT connection points within a single, compact 6U PXI chassis,” Dewey said. “This platform effectively addresses the capabilities associated with legacy, closed-architecture ATE systems while offering the flexibility and performance needed for next-generation functional test applications.”

He said attendees also showed strong interest in the ultra-rugged, PXI-based MTS-207 platform and its derivatives, such as the MTS-206/916 test set, which support a range of flightline test applications including armament and avionics test for the A-10 aircraft as well as I-level test for the Maverick missile.

Courtesy of Marvin Test Solutions

For software products, Dewey said, “There was interest in our TPS conversion tools for rehosting/converting test programs and digital test vectors associated with legacy test systems. In addition, the company has introduced a new version of ATEasy called ATEasy-Lite, which Dewey described as a full featured, cost-effective test-executive/test-development environment designed specifically for OEM suppliers of functional test systems.

Focusing on RF/microwave

John Stratton, business development manager for defense and aerospace at Keysight Technologies, said, “One of the issues that seemed to be of high interest was Keysight’s approach to common instruments for RF and microwave testing for the military. Keysight’s high-performance PXI-based instruments were designed to meet the combined specifications of all the individual services. We used the specifications of all Keysight’s legacy box instruments (used in CASS, VDATS, GPATS, and NGATS) as design requirements as we developed our latest instrumentation. Of particular interest was how Keysight was able to get 50-GHz capability into a PXI form factor. This highly configurable design allows our customers to only add the capability they need and insert new performance without replacing what is in their current system.”

Stratton said Keysight continues to invest in the MIL/aero test marketplace. Recent introductions include fast switching synthesizers that focus on the radar and EW marketplace. “Additionally,” he said, “Keysight just introduced a new MIL Radio Reference solution, which is focused at the radio and avionics manufacturers and support organizations.”

Also during Autotestcon, he added, Keysight debuted the M9393A PXIe 50-GHz vector signal analyzer, which addresses a number of military segments including radar, EW, and satellite manufacturing.

Courtesy of Keysight Technologies

vanEijkelenburg of Pacific Power Source highlighted ways in which his company helps customers support their products for long periods of time. “Several of our programmable AC power sources have been deployed in these ATE systems for 30+ years, and we continue to support these with service, spares, upgrades, and in many cases new production units,” he said. “One key advantage PPS offers is a common user interface and programming syntax across its entire product line, making upgrades easy without impacting TPSs.”

Some recent introductions by Pacific Power Source include a line of compact, single-phase rack-mounted AC power sources with higher power density than competing models, he said. For example, the ADX Series provides cost-effective programmable power for both bench and ATE. “These models ranging in power from 1 kVA to 1.8 kVA garnered much attention at the exhibit due to size and pricing,” he added.

Courtesy of Pacific Power Source

From breakout boxes to interconnect

Bob Stasonis, director of sales and marketing at Pickering Interfaces, said at Autotestcon the company introduced a modular breakout system, which was designed in partnership with Opal-RT for hardware in the loop simulation testing applications. “There was strong interest by many of the prime military contractors and systems integrators,” he said.

Courtesy of Pickering Interfaces

Stasonis added, “Our products generally are aimed at a broad range of applications and industries. In most cases, we do not normally produce products strictly for MIL/aero customers. We have had a lot of success with MIL/aero customers in the areas of high-density low-power matrix switching (using our BRIC family of matrices).” He added that the company also has had success in high-current (10 A or greater) applications and sensor emulation (more specifically, strain-gage emulation).

Chris Gibson, product manager for data acquisition at VTI Instruments, said VTI presented its new ruggedized data-acquisition instruments, including the RX0124 24-channel high-performance bridge, for aerospace test. “We featured two 24-channel dynamic strain and charge input measurement devices as well as a 32-channel precision thermocouple and voltage instrument,” he said. “The products … have drawn considerable interest, particularly in jet engine test applications in which there is a desire to move the data-acquisition instrumentation as close to the test article as possible. To do this, we provide an Ethernet/LXI interface so the instrumentation can be distributed across the engine and implement IEEE 1588 to synchronize all measurements. The devices are rated to operate in an environment extending between -20°C and +60°C.”

Courtesy of VTI Instruments

Huntron demonstrated its latest power-off Huntron Trackers and automated test systems and highlighted the new AACAT robotic test system for functional test. “The AACAT system provides a path for rehosting legacy tests, efficiently and effectively reducing the overall time to rehost the original test,” said Jim Crosson, sales and marketing manager for Huntron.

Other demonstrations included a data-streaming test system featuring ADLINK’s PXES-2590 nine-slot 3U PXI Express chassis with a PXIe-3975 controller; the PXI-9527 24-bit, high-resolution dynamic signal acquisition (DSA) module; the MXC-6300 fanless, embedded computer; and the PCIe-PXIe-8638 PCI Express-to-PXI Express expansion kit. A dynamic rotor balance analysis system featured ADLINK’s USB-2405 DSA module demo kit, the MXC-6300 fanless, an expandable computer, and Vibrant Technology software.

JTAG Technologies demonstrated its mixed-signal JTAG tester, the JT 5705, which combines a JTAG TAP controller plus digital and analog I/O in a compact desktop package. The company also highlighted its other boundary-scan controllers as well as software support for Teradyne’s Di-050 and HSSub hardware. And Wireless Telecom Group highlighted its RF peak power meters and RF/analog AWGN noise generators, representing its Boonton and Noisecom brands including the Boonton 55 Series USB peak power sensor.

Interconnect technology was a focus as well. MAC Panel showcased its APEX hybrid combination contact-pin connector announced at NIWeek 2015. The company said a key to achieving maximum value from PXI-based ATE is using the same instrumentation with interchangeable mechanics to test multiple products, adding that the APEX hybrid connector with combinational contact-pin support reduces costs of test with its flexible configuration capability. The APEX hybrid delivers a modular cabled mass interconnect that handles electrical signals from DC to RF, and it is suited for high connector-reinsertion environments found in high-volume product test. In addition, MTS demonstrated its GX7016 with a MAC Panel Scout receiver.

Courtesy of Marvin Test Solutions

Virginia Panel highlighted its new i2 MX connector, which, the company said, builds upon the success of the popular i2 Micro iCon, offering a configurable connector in the same 0.8-inch footprint. Combined with its slimmer metal engagement knob and its oblong cable exit, the i2 MX provides maximum cable bundle clearance and improved stackability. And Teradyne, which highlighted its HSSub high-speed subsystem, also presented a paper on introducing PXI instrumentation into an existing VXI tester that incorporates the VPC Series 90 interface.1

Continuing innovation

Since the show, companies have continued highlighting products for MIL/aero applications. For example, Universal Switching introduced its System MS2010A— a high-performance DC to 18-GHz coaxial blocking matrix designed for high reliability and very low MTTR. It is available in configurations from 4×4 to 10×10 in a compact 2RU unit. It finds use in automated test equipment, ground stations, telecom equipment, uplink or downlink antenna feeds, communication centers, and satellite installations.

Dave Sigillo, vice president, Seica USA, described his company as a supplier of large ATE solutions for MIL/aero applications at the I-Level and D-Level, both for legacy replacement and for new, high-performance technologies. “Taking advantage of our common hardware and software architecture and of the openness of our systems, we have now scaled down these architectures to the MINI Line, keeping the same performance,” he said. The MINI Line offers functional, high-speed, in-circuit, and JTAG test capabilities on a compact architecture. MINI Line equipment can be configured as a standalone, benchtop, or portable tester, or it can be used as a building block for other special to-type test equipment designs or upgrades. The MINI Line operates either under the full suite of the company’s VIVA proprietary environment or under the NI LabVIEW/TestStand. Sigillo added, “While it supports direct conversion of legacy test languages or simulators, it can be directly programmed from an Excel spreadsheet, from the Python test language, and more.”

Courtesy of Seica

Paul Groome, vice president, Digitaltest, said his company has recently introduced products that can have an impact in the MIL/aero test environment. For example, “Digitizer 2.0 provides the tools for MIL/aero manufacturers and support organizations to extend the life of important avionics and military systems by automatically regenerating CAD data from a loaded board,” he said. The new generation of the company’s nondestructive, reverse-engineering software was developed as part of the INPIKO project for maintenance of long-life products, conducted in conjunction with Fraunhofer IPK and other companies.2 “Digitizer 2.0 can link with data from other systems [including optical and X-ray equipment] and provides new methods to determine unknown component values using new innovative metrology techniques,” Groome said.

“In addition,” he continued, “we have made some significant additions to our Condor flying probers to enhance our capabilities for MIL/aero environments. The New MTS505 Condor flying-probe system has a Z-axis enhanced conveyor, measurement systems, and fault coverage modules. Uniquely, for companies that require the highest quality of test, the new measurement system (AMU 5.0) when combined with FailSim allows users to achieve the highest most accurate fault coverage, which is quantified by FailSim, so you can be assured that all tests are finding the defects you expect them to. Our ‘Soft Landing’ features provided on the Z-axis allow you to control the pressure of the probe on the board, ensuring no marking in solder joints.”

From factory to flightline, and from DC to many gigahertz, you can expect test equipment companies to continue delivering innovations for MIL/aero applications. EE-Evaluation Engineering will have an update on the topic in conjunction with Autotestcon 2016, scheduled for Sept. 12-15 in Anaheim, CA.

References

- Paton, K., “Introducing PXI Instrumentation Into An Existing VXI Based Tester,” IEEE Autotestcon Proceedings, November 2015.

- Stark, R., et al., “Advanced Technologies in Life Cycle Engineering,” Proceedings of the 3rd International Conference in Through-life Engineering Services, Volume 22, 2014.

For more information