Display Inspection: Flexible OLED displays drive market disruption, manufacturing innovation

Consumer electronics manufacturers reside between a rock and a hard place. They must continuously innovate in order to compete in the mass market, yet they’re tightly constrained by unrelenting cost pressures. The recent emergence of flexible OLED displays is a prime example of a cutting-edge technology that electronics manufacturers must pursue to maintain market relevance—but producing these displays is expensive, and the number-one reason for this is yield.

Yield—measured in this case by how many manufactured flexible OLED displays are high integrity and therefore usable vs. how many are defective and therefore must be discarded—has to be factored into the end product design at the outset, or the product could be prohibitively expensive to produce at commercial scale.

As such, consumer electronics manufacturers are putting increased pressure on their display suppliers to make bigger investments in yield management. These investments should ultimately improve suppliers’ aggregate yield and, in turn, profits. But at the end of the day, it’s the suppliers that shoulder the risk of this investment.

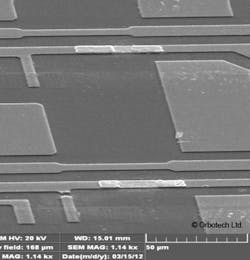

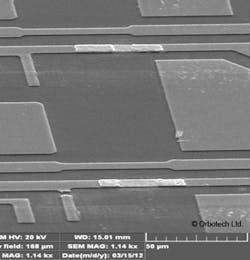

This trend is driving increased supplier interest in advanced automated optical inspection (AOI), electrical testing, and automated repair systems that can identify and repair defective manufactured devices with high precision and minimal process friction (see figure), boosting yield rates for flexible OLED displays without compromising the quality or reliability of the end product.

Nascent technology

First-generation flexible OLED display technology already has begun to find its way into the consumer marketplace, but its full potential is far from realized. Samsung Galaxy Edge smartphones and Apple Watches are among the first devices to incorporate this technology, but their curved displays are not designed to be bendable by consumers. Encapsulated in rigid, protective glass, these devices merely hint at what flexible OLED displays are capable of.

Next-generation flexible OLED displays will be foldable, rollable, and perhaps even stretchable, differentiating a new class of electronic devices, and opening a massive market opportunity for consumer electronics providers. According to research firm IHS, flexible displays are expected to make up 15% of total display market revenue in 2024, with revenue from flexible display production expected to expand at a compound annual growth rate of 44% from 2014, reaching $23 billion in 2024.

Mainstream market penetration for user-flexible OLED displays will remain elusive, however, absent the stringent manufacturing process controls required to enable sufficient yield. Here we’ll assess some of the core challenges unique to flexible OLED display production—challenges that must be overcome to ensure the cost structures required for commercial viability.

Learning curves

Manufacturers of traditional, rigid LCDs have accumulated 30+ years of experience and expertise in optimizing process efficiencies, continuously refining their process-monitoring and quality-assurance protocols to maximize yield and lower production costs. In time, these glass-based displays have become relatively easy to produce because the glass is durable and flat and acts as a protective barrier for the underlying circuitry and layers.

With flexible OLED displays, the complexity of these processes increases dramatically. These displays still leverage glass, but only as a temporary base layer upon which the flexible polyimide substrate is applied and later removed, creating the foundation for the flexible display circuitry. Intensive process monitoring is required to ensure that the polyimide is properly mixed, is administered at the right temperature, and coats the glass at the right thickness. Despite these stringent controls, the flexible polyimide substrate remains vulnerable to scratches, bubbles, dust, and other contamination.

Protecting against these defects is critical, particularly when they allow the ingress of water vapor and oxygen, which can render the OLED display unusable. Whereas a glass coating acts as a reliable barrier against moisture contamination for a rigid OLED display, seamless, flexible “thin film encapsulation” is required to effectively seal a flexible OLED display—and the encapsulating layers must be durable and yet pliant enough to enable the display to be flexed and folded. This is no easy feat.

With OLED displays, the per-pixel circuitry also is considerably denser than with LCDs. A traditional LCD may house one transistor per pixel. An OLED display, on the other hand, may house between two to seven transistors per pixel, plus one to three capacitors. And the pixels themselves are getting smaller and smaller to enable ever higher resolution displays. As the density of the pixel architecture increases, the precision of the AOI, electrical testing, and automated repair systems included in the manufacturing line also must be increased.

Rising to the challenge

Manufacturers of flexible OLED displays are grappling with a myriad of new variables—materials, design layers, and processes—all of which increase manufacturing complexity and may negatively impact yield at the outset of production. By making sound, calculated investments in advanced AOI, electrical testing, and automated repair systems, however, these manufacturers can ramp up their process efficiencies, improve yield, and drive greater profitability.

The acute challenge of detecting and identifying defects among multiple layers of transparent materials—from the polyimide substrate to the thin-film encapsulation—can be overcome by leveraging submicron-precision and multimodal inspection equipment. With the capability to illuminate materials from different angles and with different light wavelengths (dark field illumination, bright field illumination, etc.), defects can be readily identified anywhere in the layer stack. And whereas conventional AOI systems can require multiple scans to inspect materials under different optical conditions, multimodal systems can acquire all of this data in a single pass, enabling significant time savings.

Similarly high precision systems can be deployed for automated repair processes. Mechanically, the system should be extremely stable, immune to vibration, and afford ultra-accurate laser control that will allow, for example, the capability to cut a short-circuited metal line within a 3-micron gap between two 4×4-micron transistors.

In terms of optical capabilities, an ideal repair system will provide high-magnification review and the flexibility to choose between very different optical wavelengths for the laser. This, in turn, enables the laser to ablate or drill through a single layer in the stack without damaging adjacent layers. With the added capability to automatically define and modify the precise geometric shape of the projected laser beam, sophisticated “patterned” repairs can be applied.

Testing for success

Whereas advanced AOI and automated repair technologies are already well positioned for use today in manufacturing flexible OLED displays, continued innovation still is needed to perfect the requisite array-testing capabilities. Testing technologies, in time, will evolve beyond the flat-panel-display domain to encompass flexible displays, enabling the rigorous quality controls commonly employed today by LCD manufacturers.

Looking ahead, voltage imaging technology holds the promise to overcome the array-testing challenges associated with flexible OLED displays, offering the capability to provide a high-resolution voltage map of the entire display. The pixel voltage data gleaned via this process can enable a test system to determine in real time if a pixel and/or line of pixels is defective.

“Designing for testability” is a key concept that manufacturers of flexible OLED displays are encouraged to embrace at the outset of their pixel design process. By consulting with an experienced array testing technology expert early in the cycle, manufacturers can optimize pixel designs to help ensure more effective and efficient testing processes on the backend.

Investing in the future

Flexible OLED displays will literally transform future generations of smartphones, tablets, wearables, and beyond and will form the foundation for completely new categories of devices. It therefore is incumbent upon display manufacturers to invest appropriately in the advanced AOI, automated repair, and testing technologies needed to optimize yield and profitability across the ecosystem, from the display manufacturers themselves to the consumer electronics providers that depend on them.

About the authors

Shulik Leshem is the vice president of marketing for Orbotech’s Flat Panel Display (FPD) division. Leshem joined Orbotech in October 2014 where he initially served as the division’s director of strategic marketing. Previously, he worked at HP Scitex in a number of positions including worldwide marketing manager and current business manager. He has an MBA from Bar Ilan University and B.Sc. in electrical engineering from the Technion Institute of Technology.

Noam Cohen is a FPD consultant engaged with Orbotech. He previously served as the commercial platforms and segments manager at HP Indigo and before that in a variety of management roles at Orbotech including corporate director of business development and vice president of marketing of the FPD division. Cohen has an MBA from INSEAD and a B.Sc. in electrical engineering from the Technion Institute of Technology.