ECT reports ZIP spring probe wins head-to-head competition

Fontana, CA. Everett Charles Technologies (ECT) announced it has won a head-to-head evaluation using ZIP Z0-040 probes made with HyperCore material in a high-volume production environment at a large Asian OSAT. The Z0 probes reached 250k insertions, more than a 500% increase in probe life compared with a competitor’s spring probe while exceeding first-pass yield expectations.

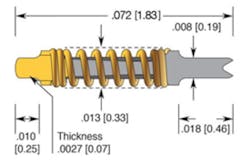

Specifically, the Z0-040RHJ went head to head in an evaluation with another industry leading probe. The application required reliable and repeatable contacting of NiPd pads, which are known to be challenging due to their hardness and abrasiveness. The primary goal of the evaluation was to increase probe life and lower cost of test. The target parameters for success were to exceed 200k insertions while maintaining consistent 1st pass yield performance.ZIP Z0 probes built from HyperCore present a new level of accuracy, scalability and performance, the company said. The proprietary non-plated, homogenous probe material possesses properties that prevent oxidation, ensuring premium performance throughout high volume production cycles. With 600 Knoop hardness, the probe is inert to common wear related to contacting hard, rough surfaces and abrasive cleaning. Additionally, ECT’s patented ZIP Z0 probes feature a number of innovative design features that provide superior contact capability. ZIP Z0 probes have a large internal contact area resulting in low contact resistance, superior bandwidth and excellent conductance.

Tony DeRosa, senior product manager, explained, “In applications like this one, our proprietary Hypercore material provides a substantial advantage due to its extraordinary hardness.” He added that the customer has begun to transfer contactor designs to Z0.

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.