Spectrum says digitizer is key to record-breaking indoor magnetic fields at University of Tokyo

Grosshansdorf, Germany. Spectrum Instrumentation reports that the International MegaGauss Science Laboratory, part of the Institute for Solid State Physics (ISSP) at the University of Tokyo, is attempting to set a new world record for the highest ever indoor magnetic field. To do this, the ISSP needed to improve the precision of capacitor-bank firing processes with subnanosecond measurements and has installed a Spectrum Instrumentation digitizer to assist. The fields are used to study the physical properties of solid-state materials as they are subjected to ultrahigh magnetic fields and to research new materials and control their phase and functionality. The laboratory’s pulse magnets can currently generate up to 87 Tesla (T) by nondestructive methods and from 100 T up to 760 T (currently the world record for the strongest field generated indoors) by a destructive process.

To optimize the magnetic fields generated by the laboratory’s MegaGauss machine, the trigger events that fire banks of large capacitors (Figure 1) have to be triggered within 10 ns of each other. To achieve this level of precision, the trigger signals for each capacitor have to be examined to determine their key characteristics and timing relationships to ensure optimal firing every time, because the physical parameters of the MegaGauss machine restrict firing to just a few shots per day.

In order to capture and analyze the trigger signals, ISSP required a fully synchronous, 10-channel digitizer system that delivers a single-shot sampling rate in excess of 1 GS/s. The high sampling rate allows the shape and frequency content of individual trigger pulses to be revealed, while fully synchronous sampling ensures interchannel timing measurements can be consistently made with sub-nanosecond precision.

A further complication is the fact that the MegaGauss machine generates dangerously high magnetic fields that are potentially unsafe and can easily interfere with the measuring instrumentation. Care needs to be taken to shield both equipment and operators. The measurement system needs to be located in the laboratory while the operator adjusts and monitors the experiments from the safety of a control room (Figure 2). As such, the digitizer system must be able to operate remotely and be controlled over the laboratory’s network.

The solution was the DN6.221-12 digitizerNETBOX system from Spectrum Instrumentation. This unit met all the necessary technical requirements, offering 12 fully synchronous channels, each sampling at 1.25 GS/s. As digitizerNETBOX units are LXI-compliant instruments, they allow full remote control and data transfer over a Gigabit Ethernet connection.

The digitizerNETBOX systems offer advantages over other digitizers as they provide a turnkey solution to multi-channel acquisition. Users can select the desired number of digitizer channels as well as fundamental specifications such as the sampling rate, resolution and on-board acquisition memory.

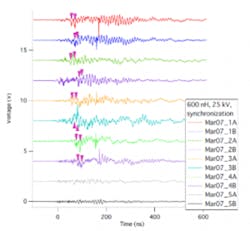

The units also come with SBench 6-Pro software that allows the user to quickly set up the system and start making measurements. SBench 6-Pro features an easy-to-use, graphical user interface that allows multi-channel waveform display, data analysis and documentation. Acquired and analyzed signals can be stored and exported to other devices, or other software programs, in a number of formats such as MATLAB, ASCII, binary, and wave (Figure 3). Signal characteristics are easily identified and critical timing measurements can be made. Data is also exported for further analysis and documentation.

The laboratory is now able to further optimize the performance of the MegaGauss machine with the expectation that they will be able to generate the world’s highest ever in-door magnetic fields later in this year.