Getting a Grip on Nanowatt to Megawatt Measurements

Whether you are powering a mobile IoT device or drawing energy from the grid, power quality will be a concern, requiring accurate measurements. Whether you are measuring the efficiency of an electric vehicle or conducting consumer-appliance compliance tests, you’ll need accurate, fast results and the ability to make use of the data you collect. Dedicated power analyzers and software can help, and some general-purpose instruments can be adapted to the task as well.

Engineers face a variety of challenges when it comes to power measurements. Those challenges relate to higher efficiencies, higher power densities, lower standby powers, lower DC consumption, and very high-frequency of operation, according to Seshank Malap, applications and marketing engineer for power at Tektronix.

Mike Craig, IntegraVision R&D project manager at Keysight Technologies, zeroed in on one particular challenge customers face: understanding the total uncertainty of the measurements they are making with their power analyzer. “A very typical use case for a PA is to measure the total efficiency of a power-conversion device,” he said. “When computing the uncertainty of an efficiency measurement, the error terms from multiple voltage and currents measurements must be considered. Be very wary of top-line or ‘banner’ specifications about basic power accuracy—it’s almost always necessary to work through the detailed product specifications to get a true picture of the aggregate measurement uncertainty for your application.”

He added that some analyzers have impressive specifications in a narrow frequency range—for example, at the AC mains frequencies of 50 Hz/60 Hz—but have only average or mediocre performance in other frequency bands or operating conditions. “For an application where different types of signals must be measured to compute total efficiency, such as a solar inverter with DC inputs and AC outputs,” he said, “the benefits of very good measurement accuracy for one type of signal may be largely mitigated by the poorer measurement accuracy associated with the other signals that are part of the efficiency calculation.”

According to Krista Tweed, applications engineer for test and measurement at HBM, “Our customers need a testing solution that provides accurate, real-time results quickly. It is very helpful to be able to reduce the time required to create an efficiency map from many hours to a few minutes. But they also want to be able to access the raw data that was used to create the calculations in the case of unexpected results”—so they can understand what happened without having to run additional tests.

Frank Healy, power-quality product marketing manager at Fluke, addressed a similar concern. “The biggest challenge for users is in understanding what the measurement data means,” he said. “How can they convert the data into information that will enable them to take actions to improve their system?” And to help customers access data, Healy said, Fluke has implemented Wi-Fi connectivity to its instruments and supports simple download directly to a USB thumb drive.

Sam Shearman, power-analyzer product manager at Yokogawa, also cited accuracy as a key issue. “As efficiency requirements improve, it becomes increasingly important that you have the accuracy to characterize small changes,” he said.

Another challenge involves traceability requirements to standards such as NIST and ISO 17025, Shearman said, adding, “Engineers must comply with these and other standards to qualify for approval markings on the products that they are designing.” Yokogawa addresses this challenge by offering NIST and ISO 17025-accredited calibration that many customers purchase with the company’s instruments. “Having the manufacturer do the calibration is a benefit because of convenience and the understanding of the instrument that only the manufacturer can provide,” he said. Shearman and a coauthor addressed accuracy, traceability, and other power-analyzer issues in an article published earlier this year.1

Craig at Keysight recounted yet another challenge: capturing and observing transient disturbances. “While many competitive analyzers display waveforms and are capable of detecting transients, the triggering and visualization capabilities are often very limited,” he said. To address the limitation, Keysight in 2016 introduced the IntegraVision PA2203A power analyzer, which targets 3-phase applications (Figure 1). “The PA2203A features an oscilloscope-like interface and waveform visualization combined with the accuracy of a traditional power analyzer to provide the fastest time-to-insight on the market,” Craig said.

Courtesy of Keysight Technologies

“By incorporating the interface and display of a traditional oscilloscope, the PA2203A makes it very easy to quickly capture and analyze a transient feature in a waveform.” He added that captured waveforms can be stored on a USB drive for post-processing and additional analysis.

Craig continued, “Since the release of the PA2203A model, Keysight added new features via firmware updates including a trend-chart capability for extended power-quality monitoring and an enhanced harmonic-analysis mode that allows the user to measure the relative phase angle of voltage, current, and power harmonics of 3-phase signals.”

As for application areas, he said, “Keysight has seen the adoption of the IntegraVision power analyzer across a range of industries, including EV/HEV component test, aerospace/defense, and white-goods compliance testing. Another area where Keysight has had success is power-quality monitoring and analysis in datacenter power-distribution applications.”

Tweed described HBM’s eDrive advanced power analyzer as easily scalable to address a range of power-analysis applications, with capabilities including the measurement of a 3-phase power source, a simple drive line (including power source/sink, inverter, and electric machine), or a complex motor-generator system where two electric machines work against each other. “A single GEN Series mainframe can measure up to 51 power channels simultaneously,” she said. “eDrive can be adapted to support complex setups such as a multilevel inverter, a hybrid drive, multimotor setups, or measurement of 5-, 6-, or even 12-phase motors.” Since eDrive calculations are cycle-based, the system is suited to providing accurate results in dynamic applications, she added.

The standard eDrive input module supports up to ±1,000 V directly, she said, and HBM has probes for input voltages up to 5 kV RMS. In addition, a fiber-optic solution can support near-infinite isolation for almost any voltage level.

HBM is continuing to expand the capabilities of its eDrive advanced power analyzer. “We now offer a mid-level configuration for those that are not testing the entire drive train, but rather only the inverter-driven machine or the power source,” said Tweed. “We also support a CAN trigger option that enables a CAN message to start, stop, or trigger the eDrive system. The most important recent improvement for our advanced users is additional flexibility in the Perception software for customizing the real-time calculations (Figure 2). With this additional flexibility, even users with complex, unusual machines can easily acquire the data in real-time to create a motor-map in minutes.”

Courtesy of HBM

She added, “The eDrive software suite is specifically designed to support power-analysis applications. Based on the application selection, eDrive automatically creates the calculations for a standard analysis, including total power, apparent power, reactive power, power factor, mechanical power, and efficiency.” Users can expand the analysis capability if they require features such as dq0 transformation or must deal with a non-typical input, such as a 5-phase inverter.

Fluke covers a range of power measurement applications, according to Healy. For precision power measurement, Fluke offers the Norma range of analyzers, which are typically used during the development and test of motors, transformers, variable-frequency drives, UPS systems, and other electrical infrastructure equipment. For measurements in the field, he added, Fluke offers a range of portable power analyzers with specific models for motor analysis and for shipboard and 400-Hz power systems. “The portable analyzers are used to discover the state of power-quality health of the system, which can be anything from the substation right through to individual electrical loads inside a facility,” he said.

The company this year introduced the Fluke 1740 Series, which primarily targets electric-power utilities and large industrial facilities. Healy described the series as power-quality loggers installed on a semipermanent basis to look at power, energy, and power quality over time. The product indicates to users if they have connected the logger incorrectly and allows automatic correction without having to access the measurement leads and probes. “Also,” added Healy, “the products are powered from the measurement circuit, which makes installation much simpler—no need to find power outlets or run extension cables for instrument power.”

The company has also recently upgraded the Fluke 438-II motor and power-quality analyzer (Figure 3). “This product enables users to discover the efficiency of their electric motors simply by taking electrical measurements,” said Healy. “The instrument takes the voltage and current values and calculates the torque, speed, mechanical power, and motor efficiency using a proprietary algorithm according the requirements for NEMA-rated motors. The new Fluke 438-II can make these measurements on both directly connected motors and inverter-driven motors.”

Courtesy of Fluke

In addition, said Healy, Fluke is continuously making improvements in its software-reporting tools to simplify the process of converting data into useful, coherent information. “One of the latest such innovations is ‘one-click’ reporting, where we take measurements over many days and summarize the data into a single standard report with just one click of the mouse,” he said.

Inverter design

Yokogawa’s power analyzers include the WT3000E, which, Shearman said, offers power accuracies of 0.01% of reading. “Inverter design is an example where engineers designing such devices are challenged to improve efficiency by just a few decimal places,” he said. “To validate small improvements in efficiency, engineers need a device capable of extremely high accuracy and precision.”

Recently, the company introduced WTViewerE software (Figure 4), which Shearman described as companion software for Yokogawa power analyzers developed to perform common operations when connecting a power analyzer to a PC. “With this software, users can control up to four WT Series power analyzers from a PC at the same time,” he said. “It enables synchronous data acquisition of multiline power parameters that a single WT unit cannot cover. For instance, when four 6-element WT1800E Series power analyzers are connected, the combined units can be considered as a single 24-element WT unit. With this configuration, users can calculate efficiency with inputs and outputs defined on any of the channels.”

Courtesy of Yokogawa

In addition, Shearman said, “The software also allows users to locate and view important sections of waveforms and measurement trends with zoom and scroll, with live updates of measurements as they do so.” He added that measurements and waveforms can be exported as Excel-compatible files or in a space-efficient binary format.

Shearman added, “Another core feature is the ability to remotely configure power analyzers, allowing users to not only save and load configuration information…but also copy configuration information from one unit to another. The software presents controls and indicators that mirror those on the power analyzer in order to set or retrieve parameters.”

Shearman also noted that customers can face challenges related to characterization of higher channel -count systems. “The WTViewerE software allows users to synchronize up to four WT Series power analyzers and enables users to do efficiency calculations across all of the inputs and outputs of their system,” he said.

Other dedicated power-analyzer products include the Hioki PW3390, which the company describes as a high-precision, broad-range power analyzer for measuring electrical power from DC to inverter frequencies. It provides four input channels to support single- and 3-phase inverter motor systems up to 4,000 A AC/DC with ±0.04% basic power accuracy and a 200-kHz measurement band.

Introduced earlier this year, the PW3390 is effective in evaluating the fuel performance of automobiles, the company says. Hioki recently posted a video2 showing the instrument, paired with Hioki current clamp sensors, being used to perform tests in accordance with the Worldwide Harmonized Light Vehicle Test Procedure (WLTP).3 The combination can achieve high-accuracy measurements even within hot engine compartments, the company says.

Another instrument for power analysis is the Vitrek PA900 precision harmonic power analyzer. The company says the instrument offers 100 full precision readings per second and measurement bandwidths sufficient to handle 5 MHZ waveforms. It can accommodate crest factors as high as 30:1. Applications include LED and HID lighting, solar-panel energy-output measurements, and efficiency testing on inverters and PWM motor-drive systems on electric vehicles.

From power analyzers to DMMs

According to Malap at Tektronix, his company offers “…a wide power-solutions portfolio that provides end-to-end solutions for power electronic designer, working on AC/DC power supplies, DC/DC converters, solar inverters, UPS systems, battery chargers, battery-management systems, and other power-conversion applications for IoT and wireless sensor nodes ranging from ultralow power (nanowatts) all the way to extremely high power (megawatts).”

Specific Tektronix instruments for power analysis include the PA1000 and PA3000 power analyzers, which come with free PWRVIEW software to help users monitor, log, and analyze their data remotely for safety and convenience, Malap said.

“The software also comes packaged with selected regulatory standard tests and application modes for testing power consumption, efficiency, standby power, inrush current, current harmonics, and input power analysis with easy PDF reporting,” he said, adding that Tektronix offers low-standby-power measuring capabilities down to 5 mW, along with high basic (V/I) accuracy of 0.04%, helping power-supply designers measure high efficiencies and ultralow standby power. Offering many features as standard, he said, Tektronix power analyzers support single- and 3-phase power-analysis applications including power supplies/converters, battery chargers, home and office appliances, LED drivers, inverters, UPS systems, and motor drives.

Tektronix’s offerings, including its Keithley line, address power analysis from power-semiconductor characterization all the way to end-product compliance and manufacturing, Malap said. That lineup includes dedicated power analyzers as well as general-purpose instruments.

Malap provided an example of one of the latter applied to power analysis. For DC power-consumption analysis on portable products such as IoT devices and medical devices, Tektronix offers the Keithley Model 7510 graphical sampling 7½-digit DMM, which can capture the battery-drain current in all the operating states (sleep mode, standby mode, and transmit mode) of the device. The DMM7510 has 1-pA sensitivity for measuring low sleep-current draw and 1-MS/s reading speed to capture short current bursts when the device is transmitting. To capture a complete current profile, the DMM7510 has 27 million storage points. Waveforms can be analyzed using the pinch and zoom capability implemented in the 5-inch touchscreen display.”

Oscilloscopes can also serve in power-analysis applications. Malap described Tektronix’s new 5 Series scope (Figure 5) as “the perfect complement” to the company’s IsoVu probes, given the scope’s eight FlexChannel inputs and 16 bits of vertical resolution. The probes themselves, he said, offer 1-GHz bandwidth, 160-dB common-mode rejection, 60-kV common-mode voltage, and a ±2,500-V differential range.

Courtesy of Tektronix

Instruments and software

RIGOL focuses on applications up to several hundred watts of DC power with instruments capable of making measurements in submillivolt and submilliamp ranges, according to Chris Armstrong, director of product marketing. The company’s offerings, he said, are suited to mobile and IoT designs that use batteries or other energy-storage components as well as to most higher-powered electronics products that employ switch-mode power supplies.

“Engineering challenges in power vary greatly, which is one reason we offer a variety of solutions,” Armstrong said. “The biggest challenges often come from difficulty verifying operation in different use cases.” RIGOL’s approach allows engineers to verify subsections independently and then together.

He elaborated, “What RIGOL does differently is that we provide tools for engineers to investigate bugs and reliability issues from a number of different perspectives,” he explained. “Engineers can start with our linear programmable power supplies as a great low-noise, precision power source for their devices up to 190 W. Understanding a device’s performance under clean power is often the most important step in understanding the root cause of performance and reliability issues.”

Separately, he said, engineers can test proposed power supplies under load using the company’s new DL3000 Series electronic loads (Figure 6). “These instruments can be programmed to evaluate any power supply, battery, or alternative-energy source that will ultimately deliver DC power to a device,” he said, adding that once both the power output and power requirements are well understood, engineers can utilize RIGOL’s suite of power-analysis tools with its oscilloscopes to analyze the efficiency of a switch-mode power supply and understand important factors including its safe operating area and harmonic components. “With our recently released DS2102E oscilloscope,” he said, engineers can now purchase a system that includes a current probe, scope, and Ultra Power Analyzer software for less than $2,400 total.”

Courtesy of RIGOL

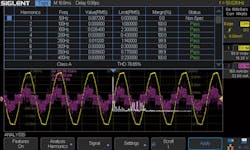

And finally, Siglent plans to release a power-analysis application for use with the its SDS2000X Series of oscilloscopes by year-end, according to Derek Song, SDS2000X product manager. “The application is currently in the final round of beta testing, and so far, we have achieved some very positive results,” he said, adding that the primary measurements include ripple, MOSFET losses, harmonics, and power factor (Figure 7).

Courtesy of Siglent

“It is designed to give engineers a tool that can help them optimize and test their power-supply designs,” Song said. “Since this is an application integrated into an oscilloscope platform, it addresses general power-supply design and test. Coupled with the proper accessories (voltage and current probes and de-skew fixturing), the scope/software system can assist designers working on small battery-powered IoT/wearable devices all the way up high-voltage/power applications like electric vehicles. It is as simple as changing out the probes.”

References

- Gatheridge, Bill, and Shearman, Sam, “Selecting the right instrument for electrical power measurement applications,” EE-Evaluation Engineering, February 2017, p. 16.

- “Using the Hioki PW3390 to Evaluate Vehicle Fuel Consumption Performance according to WLTP,” YouTube Video, Hioki E.E. Corp., Aug. 31, 2017.

- “What is WLTP and how does it work?” WLTP Facts.eu.

For more information:

About the Author

Rick Nelson

Contributing Editor

Rick is currently Contributing Technical Editor. He was Executive Editor for EE in 2011-2018. Previously he served on several publications, including EDN and Vision Systems Design, and has received awards for signed editorials from the American Society of Business Publication Editors. He began as a design engineer at General Electric and Litton Industries and earned a BSEE degree from Penn State.