Leti proposes curving technology for optical equipment

San Francisco, CA. Leti, a research institute at CEA Tech, has developed a new curving technology for optical sensors and microdisplays that improves performance, enhances field of view, and compensates for aberrations in optical applications.

The technology curves components such as CMOS imagers and charged-couple device (CCD) imagers for mobile phones, cameras, telescopes, medical-imaging tools, and industrial-control equipment. Other uses include IR sensors for astronomy, defense, and drones as well as microdisplays for automotive, augmented-reality, and virtual-reality applications.

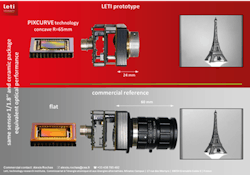

Leti’s fully functional prototype of this technology—called PIXCURVE—was presented in the paper “Curved Sensors for Compact High-Resolution Wide Field Designs: Prototype Demonstration and Optical Characterization” at SPIE Photonics West 2018 this week in collaboration with LAM (Laboratoire d’Astrophysique de Marseille).

“Curved sensor technology is a disruptive approach for imaging applications such as photography, videography, computer vision, surveillance, and many other applications,” said Bertrand Chambion, one of the paper’s coauthors. “In recent years, we have seen very strong interest in curved electronics, particularly for opto-electronics systems whose performance improves, while size, complexity and cost are reduced.”

The demonstration is based on a 1/1.8’’-format, 1.3-million-pixel CMOS image sensor. The standard sensor structure consists of a 7.74×8.12-mm silicon die glued on a ceramic package. Electrical connections are wire bonded from the die to the package surface and, then, to the interconnection board. A glass cover is placed on top for mechanical protection.

Leti’s technology uses a grinding process to get the sensor below 100 µm thick, which makes it mechanically flexible. It is then glued onto a curved substrate, which determines its final shape. A wire-bonding process developed for electrical connections is used to prevent damages on the thinned dies. The radius of curvature is 65 mm. This prototype is compared to the equivalent commercial solution with flat sensor in the figure.

This process is compatible with any sensor size and with large-scale manufacturing processes.