Punk rock oscilloscopes: A new genre of test gear for automated test environments

“Questioning anything and everything, to me, is punk rock.” — Henry Rollins, punk rock pioneer

If Henry Rollins were an engineer instead of a media icon, he’d still say it’s time to question everything. Today’s automated test environments (ATEs) need oscilloscopes. It’s undeniable.

But what kind of oscilloscope do they need? A traditional, box-with-buttons-and-a-screen oscilloscope isn’t necessarily the best option. ATEs have different requirements compared to design labs. Here’s a quick rundown of common ATE oscilloscope requirements. They must:

- Be low profile and rack mountable to save floor space

- Have remote control and display capabilities to give engineers a consolidated view of their ATE

- Streamline data analysis and acquisition sizes to reduce test time

- Perform mask testing to test pass/fail

All these requirements are unusual for oscilloscopes. They’re on the fringe of the test-and-measurement scene. That’s why scope manufacturers have spent the last decade questioning what their oscilloscopes should look like. Can you imagine using an analog oscilloscope on a manufacturing line?

Much like punk rockers defined a new music genre in the 1970s, new oscilloscopes are building their own subculture in the engineering back alleys of the ATE world.

Here’s what’s converting classic oscilloscope fans over to the new genre.

Low profile, rack-mountable design

Traditionally, ATE engineers had to make a choice.

They had to decide between a small oscilloscope with compromised performance and a larger, full-featured scope. Not an easy choice.

Today that choice is much less of an issue. Major oscilloscope manufacturers are actively designing oscilloscopes specifically for ATEs.They’re leveraging existing technologies and chipsets to bring full benchtop scope capabilities into tiny form factors.

Sometimes these are stand-alone units, but often they are modular, chassis-based oscilloscopes that can be combined with other types of test gear to create a custom ATE solution.

Waveform visualization

All oscilloscopes acquire data, process it, and plot it on a screen for troubleshooting and signal analysis.

But ATE engineers need to see their data from a physically separate location. They can’t stand next to their oscilloscopes all day checking multiple screens.

So ATEs traditionally tried to use digitizers in place of oscilloscopes. Digitizers just don’t cut the mustard in some areas, though. ATEs are extremely sensitive to how long each test takes. Since digitizers don’t do automatic interpolation and plotting, the end user must do it. This becomes a testing bottleneck.

Update rate and intensity control are commonplace on oscilloscopes for the design bench, but they are just recently making their way into the ATE world.

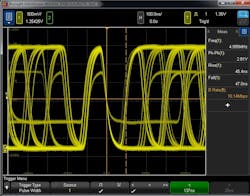

For example, look at Figure 2. This scope display shows multiple waveforms overlaid onto the screen at the same time thanks to its fast update rate. And waveform intensity controls allow the user to quickly identify errors in their signal. If you tried to see this much data at once with a digitizer, you’d be disappointed.

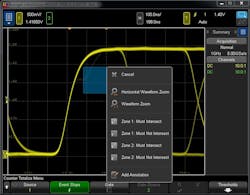

It’s also worth noting that some sort of remote connectivity is a must-have. Notice that Figures 2 and 3 are screenshots from a PC and not a screenshot from the scope itself. Ethernet or USB are preferred, but some legacy systems use GPIB and VGA for control and display.

Streamlined data acquisition

ATE test scenarios typically don’t require every bit of acquired data. Extra data means unnecessary time spent on data analysis or transfer. Much of this can be avoided using advanced oscilloscope triggers—engineers capture only the data they want to see. It can be streamlined further using oscilloscope digitization using coded commands. For example, on Keysight scopes you can use the > :DIGitize command followed by > :WAVeform:DATA? to capture and collect a smaller data size.

Sometimes engineers can even get away with zero waveform data. Simply identifying and counting trigger events is all that is needed.

Integrated tools

Advanced functionalities are also trickling down from benchtop oscilloscopes—capabilities that are unheard of in traditional ATEs. Take Figure 4, for example. This modular scope can decode and trigger on specific protocol packets and even trigger on errors.

These additional capabilities give ATE engineers unprecedented flexibility when designing and refining their test procedures.

Waveform mask testing

This one’s clear, so I’ll be brief. Like a song off a Ramones album.

Pass/fail testing is a must-have. In the past, ATE systems often required custom FPGA work to provide real-time pass/fail data. Some of today’s ATE-focused oscilloscopes, like the scope we’ve been looking at today, can run hundreds of thousands of tests per second using internal hardware. They also provide some quick troubleshooting capabilities like the ability to easily create a mask based on a previously-captured “ideal” signal and report test results as six sigma performance benchmarks.

Appropriate probing

There are two main considerations for ATE probing.

The first is signal integrity. In the past, most ATEs were only concerned with dozens or hundreds of MHz. As signal speeds increase in speed and decrease in amplitude, probing becomes more important. An off-the-shelf passive probe or cabled-in connection may not be enough for today’s test requirements. The ability to leverage higher-end probes into ATEs is crucial.

The second consideration is probe diversity. ATE oscilloscopes should work with multiple types of probes. In addition to standard passive probes, many ATEs require high temperature probes, high sensitivity current probes, high current/voltage probes, power rail probes, or extra-long cabled probes. This simply isn’t a possibility with many scopes.

Oscilloscopes for ATEs—“Question everything”

Automated test environments often place a heavy burden on the software program (and the programmer). They must perform correct analysis while characteristics are still under development or while profiling a system’s operational performance. Software processes are beyond the scope of this article, but it’s fair to say that it rides on the back of the hardware.

In the past, ATE implementers had to rely on benchtop oscilloscopes to get the job done. Times have changed. ATE scopes have come to the masses. So, throw on your black leather anti-static jacket and rock on.