On the Road to TestOps: Transforming how test & measurement data is shared

Engineering leaders know that each step in the path to development of a new electronic product is crucial—from design and simulation, to verification and manufacturing. Unfortunately, measurement results from one step in a product’s development path typically don’t seamlessly transition to the next step, and that presents a sizable challenge. Errors can occur, project development can grind to a halt, and opportunities to optimize a product’s performance can be missed. These are significant obstacles for any engineer, especially those facing budgetary constraints or short time-to-market windows. Fortunately, software engineers in the test and measurement industry are today transforming how data is shared and it’s enabling a new culture: Test Development Operations (TestOps).

Why now?

We are at a critical inflection point in business and technology. The future of cloud computing, big data, and machine learning are being incorporated into our lives at an ever-increasing rate. Yet deriving value from these modern technologies in a way that touches design, test, and manufacturing is a challenge involving not just individuals, but large teams.

At the same time, product development is not as linear as it once was. Concepts and ideas are moving faster than ever before, and there are new, more complex cycles of design, test, and prototyping. Adding to that complexity, modern engineering teams are often spread across geographically diverse regions, engineers are changing companies at an astounding rate, and more and more managers are demanding real-time updates on team progress.

Engineering managers have already leveraged the time-saving advantage that comes with the use of electronic design automation (EDA) software tools. They have also benefited from the powerful advances in design and simulation. However, that alone is not enough. The gating factor to accelerating product development now lies in bridging the gap between design and test.

Consider for a moment that the number of required tests during product development is increasing rapidly and engineers must manually program the same test multiple times. Test engineers now spend hours correlating measurements from their design teams, while software engineers write workarounds because their hardware and software don’t natively talk to one another. Finding a way to bridge this gap has never been more important.

Bridging the gap

For many, the answer is TestOps, an alternate approach to traditional testing that helps engineers accelerate test development by removing the barriers that slow it down. It is based on two key pillars:

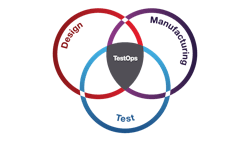

- A TestOps culture. TestOps aligns with the philosophy that teams perform better if they collaborate with each other in a shared work environment. The TestOps culture that results should pervade the whole organization, and include the design, test, and manufacturing teams (Figure 1).

- Equipment modernization. By modernizing equipment, teams can develop, deploy, analyze, and release test projects quickly and reliably. This includes both the software and hardware that automates tasks, as well as the processes between the design and test development teams.

When teams and companies adopt TestOps, the benefits are accelerated product development, higher product quality, and lower cost due to improved efficiency. The engineers themselves also benefit from a greater sense of connectedness with their colleagues and ownership of their work, the result of which is higher productivity and more creative problem-solving.

Where the rubber meets the road

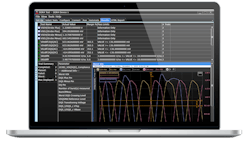

To better understand the transformative power of TestOps, consider the example of a Double Data Rate (DDR) memory design. These designs are growing more complex with each new generation, as is the complexity of the simulation and test configurations. As a result, simulation and test setup times have become significantly longer. Plus, the added complexity makes it harder to correlate simulation and test data, decreasing confidence in designs and resulting in longer troubleshooting cycles and missed delivery schedules.

Transforming industries with TestOps

The DDR memory design process is just one scenario in which software is transforming how test and measurement data is stored and analyzed. In truth, many industries are now using software to remove barriers, eliminate silos, and connect data. It’s called TestOps, and it’s transforming test and measurement.

Engineering leaders today want to increase efficiency, but many have already squeezed as much efficiency as they can out of each of their individual processes. It’s only by changing their culture and enabling collaboration across the entire design and test workflow, that they will ever make a difference in the future.