Thermal management for tomorrow’s vehicle

Download this article in .PDF format.

The automotive industry is undergoing an exciting transformation in connectivity as the need for higher speed and for more compute power is changing the game. Changes, updates and improvements are occurring nearly every day, with automakers in a race to deliver the latest safety and communication features and optimal functionality to consumers. These trends are only accelerating and the car of the (near) future will be more connected than ever before. This is creating a tremendous demand for both processing power and the ability to transmit vast amounts of high-speed data in new automotive designs.

The design challenges go well beyond simply delivering processing power and high-speed data transfer. Design engineers must also safely manage heat generated by those processes in the confines of tight vehicle packaging requirements, as well as ambient temperature fluctuations, while adhering to stringent safety and reliability standards of the automotive industry.

In considering specific design issues facing automakers and their suppliers, the challenges related to thermal management can be broken down into two basic areas of focus:

- Ensuring that the device design will generate the least amount of heat

- Designing enclosures that will help manage heat and optimize cooling in these extreme- temperature, often enclosed, harsher environments

Addressing these challenges is no simple feat, and it all begins with proper electrical and enclosure designs to achieve efficient and cost-effective thermal management.

Demand continues to increase

As early as 2025, according to estimates1, more than 85% of all new cars will be classed as “connected” and there will be more than 470 million connected vehicles on roads in Europe, the United States and China. The staggering number of connected vehicles, along with the increasing level of connectivity, is already creating a data explosion, from sensors and cameras, sonar and radar, LIDAR and GPS systems, and a host of safety, security and infotainment equipment. According to a report by Intel, one self-driving car will burn through approximately the same amount of data as 3,000 people.

Automotive connectivity components (modules, chargers, switches and gateways) will be expected to move and process that data in near real-time. That extraordinary demand for processing power requires equally extraordinary measures to manage the resulting thermal energy that’s created.

Approaches to cooling systems and design

With the advent of autonomous driving, automakers are essentially putting the equivalent of a super computer or enterprise network switch in the vehicles of the future. Minimizing heat generation and determining the best strategies for dissipating heat are both critical to the design. Ideally, a natural convection-cooling method is the most cost-effective solution to dissipate thermal energy because it does not rely on additional components, either active or passive.

Currently, the industry is widely using liquid-cooled solutions to offset the heat being generated. While effective, liquid cooled methods generate additional costs and processing (pumps, fluid—ethylene glycol or something similar to prevent freezing and a closed system to transfer the fluid.) Using liquid cooling to offset heat in an autonomous vehicle is not practical or probable in the long- term; that, along with the need to shrink the size, is creating the need for more and better thermal designs.

In addition to specifying cooling methods, R&D engineers must also address a myriad of other challenges inherent to automotive design, including:

- Mounting and other mechanical requirements

- Space constraints

- Customization and application-specific design parameters

Materials and components available today (and their ability, or inability, to handle the heat that will be generated by tomorrow’s systems). Most ICs are designed for IT computer room environments which do not meet the requirements of the automotive industry, thereby increasing the challenges for thermal cooling that is critical to end-product reliability.

Simulating and validating design innovations for thermal management

To begin, it is essential to have a full understanding of automotive products and impact of the design on thermal management, including the basics such as the solution function, location, etc., and to consider and plan for things such as:

- Vehicle space constraints

- Power level and dissipation number for each component and location

- Materials available for use—including maximum material temperatures and location of each (end user contact surfaces vs. installation contact surfaces)

- Type of airflow, if any—including in surrounding components, ducts, harnesses, etc.

- Costs

Simulation and validation tools

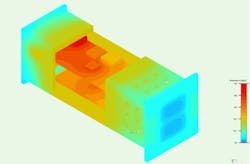

Simulation and validation of thermal design models are crucial steps in producing an accurate and credible design, and assist with anticipating and solving problems in the overall automotive design.

Accuracy is absolutely critical when designing a board and, with the advancements in technology, design requirements are becoming tighter and more stringent than ever. Detailed test and simulations are performed iteratively until simulation results correlate with empirical data. Modeling provides both security and peace of mind that the design is going to function properly before ever making it to the manufacturing floor. Steps that should be considered include:

1. Modeling

- Capturing the physics accurately

- Power levels

- Component placement

- PCB layout (copper layout)

2. Temperature plotting

3. Transient simulations, testing, and validation thermal margins vs. data sheet ratings

In addition to accurate modeling of the solution, consideration must be given as to where and how it is packaged within the vehicle, as that can also have significant impact on the effectiveness and overall cost of the design. Additional considerations include:

Module heat locations and internal heat spreading: Both how and where modules are packaged can have both advantages and disadvantages. Modules generate heat so design measures are needed to mitigate the impact. Solutions that feature embedded modules, whereby the module interface is embedded in the dashboard of the vehicle and the actual module is located elsewhere so heat can be more easily vented or dissipated, are ideal in this situation.

Inlet and laminar airflow and temperature: The ambient temperature is usually read without any airflow so, as a result, testing is performed in an enclosed environment, representing the actual condition of the vehicle and generating more accurate results. Within the vehicle, these types of components are typically packaged in areas with ducts or harnesses or other types of packing constraints.

Placement of components: The placement of various components can affect thermal design performance and consideration must be given to design decisions such as assembly direction, flow characteristics, resistance and coolant effects—to name a few.

Enclosure thermal management: Outside faceplates must have a lower temperature, as that’s where users interact with the module so it must not be too hot to the touch. This surface will act as a heat sink and steps must be taken to isolate this portion of the modules. If not done properly, these surfaces can reach temperatures of 100°C. Careful consideration of board layout, heat spreaders and other methods can ensure that these surfaces meet industry requirements.

It is important to note that any and all changes to even a single component within a vehicle can result in intended or unintended system-level changes. Making a change to the PCB layout can cause a change to the overall system (Sidebar 1).

A unique vantage point

Today, data integrity and processing power are essential to support the development of intelligent and autonomous vehicles. Improper thermal management can lead to poor performance, reliability issues, shortened product life and safety concerns. Innovative solutions meet the challenges of thermal management in the connected vehicle of the future (Sidebar 2).

Sources

1. ITSdigest, "470 Million Connected Vehicles On the Road by 2025.” February 2018.

Gary Manchester is director of new product and technology development in Molex’s Connected Mobility Solutions business unit. With 30+ years experience at Molex, He currently leads the company’s work in autonomous vehicle networks and user interface products and technology.

Don Mueller is manager of mechanical product development in Molex’s Connected Mobility Solutions business unit. He has 25 years of mechanical product development experience, and has led Molex’ mechanical product development team during the last 4 years.

Kiran Vanumati is CAE Engineer in Molex’s Connected Mobility Solutions Business Unit. He has over 14 years of experience in electronics thermal management across various industries. He is currently involved in developing thermally sound automotive infotainment and networking modules using simulation and testing.