Phase Measurements, Calibration Techniques Critical in Verifying mmWave Designs

What you’ll learn:

● The mmWave spectrum

● Accurate device characterization

● Calibration techniques

Body:

As commercial, military/aerospace, and other communications designs extend into the millimeter wave (mmWave) spectrum, engineers must adapt their testing procedures and require more from instruments such as vector network analyzers (VNAs). Shorter wavelengths associated with mmWave frequencies make phase measurements more important, while also emphasizing the need for proper calibration.

Phase measurements have even become a greater factor when verifying passive component measurements. Phase differences can be very small, depending on the material, so a VNA needs to measure even the slightest variations. It does so by comparing the incident signal leaving the analyzer with either the signal that is transmitted through the device-under-test (DUT) or the signal reflected from its input.

Influx of mmWave Designs

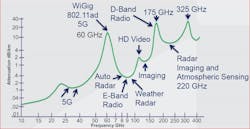

The mmWave band is defined as 30 - 300 GHz with a wavelength between 1 and 10 mm in the air. Its unique characteristics, such as penetration through fog/rain/cloud, can enable a variety of applications. The wide bandwidth of the mmWave band also makes it very attractive for ultra-high-speed wireless and satellite communications. Figure 1 shows common applications and related frequencies.

Increased frequency is only one part of the equation. Miniaturization of components/devices also adds to the importance of phase measurements in modern designs.

Waveguide Limitations

VNA calibration is important to accurately verify designs utilizing these technologies. It is particularly relevant, as mmWave measurements must be conducted over-the-air (OTA).

Accurate device characterization needs to sweep from near-DC to well beyond the harmonic frequencies to provide accurate models. Previously, engineers used different waveguides for high-frequency measurements. Waveguides are preferred for power delivery applications but there are some drawbacks for higher-frequency designs. One negative to this approach is the possibility to incorrectly mate apertures, which will adversely affect repeatability. RF leakage and slower/limited time domain analysis are concerns, as well.

Perhaps the biggest negative for high frequency designs, however, is that waveguides are band-limited. Engineers must “stitch” the measurements together when verifying their mmWave products, as a result. This is time-consuming and reduces accuracy and repeatability. A broadband VNA system can eliminate the need for waveguides by conducting sweeps of the entire range for more reliable modeling.

Calibration Technique

Testing at mmWave frequencies brings new and different measurement challenges. Minimizing measurement uncertainty is critical in the development of these new technologies.

Calibration is one way to achieve this goal.

Calibration is important because of a VNA’s internal structure, as well as external factors that include cables, fixtures, and modules. They all have behavioral characteristics, such as frequency mismatch, that must be corrected for accurate measurements. Calibration needs to be done at the DUT end of the cables for the best possible results.

Engineers must perform tedious calibration routines to remove the amplitude and phase effects of those added cables and waveguide from mmWave S-parameter measurements. For these reasons, cables should be avoided at higher frequencies because they pose challenges to calibrating. Fortunately, mmWave modules that don’t require cables (figure 2) have been developed that improve repeatability and stability by eliminating the need to calibrate the cables. They also reduce the costs associated with expensive cables.

High Frequency Calibration Options

The traditional calibration approach is to present a known standard, such as Short-Open-Load-Through (SOLT) or Short-Short-Short-Through (SSST). Standards compensate for internal losses and allow the device characteristics to be measured. Figure 3 shows the calibration algorithms, as well as their advantages and disadvantages.

With calibration techniques, there are many uncertainties that need to be addressed. These include noise floor, trace noise, and residual calibration errors. The two most important at high frequencies such as mmWave, however, are drift and repeatability.

SOLT/SOLR are often not recommended for higher frequencies due to the difficulty of fabricating a reasonable open standard beyond 65 GHz. An open waveguide flange radiates quite effectively. The result is instability and a relatively high return loss. A coaxial open circuit standard has to use an enclosed approach. At the open end of the inner conductor, a frequency-dependent fringing capacitance is formed. Even if an open standard could physically be constructed with zero length, fringing capacitance will occur. A coaxial short circuit can be constructed with almost ideal characteristics, enabling total reflection of the incident energy. Within the short circuit, there will be a small length offset. In coax, a zero-length short and a perfect shielded open exhibit 180° phase separation, while a matched load will provide 40 to 50 dB magnitude separation from the short and open.

For waveguides, the SSST/SSSR approach is recommended at higher frequencies because a load standard is not required. Accurate knowledge of the short offset lengths is also critical.

New calibration methods have been developed for mmWave designs. Up till now, engineers only had access to the cal coefficients (CCF) files. Inductance and capacitance values for the opens and shorts of the calibration kit along, with offset lengths for them, were contained in these files. It was all modeled data, so the residuals were high.

A new form of calibration kits defined popularly as a database calibration kit contains the exact S-parameter vs frequency response of each component of the calibration kit. The result is reduced residual errors in the calculations, as well as improved overall accuracy of the calibration algorithms. S-parameter vs. frequency is provided to the user instead of just the cal coefficients. This can be done from electromagnetic (EM) simulation or by transfer/real measurements done at the manufacturer’s facility. Lower ripple is also a goal, as it helps improve measurements. An example of the database calibration kit inputs is shown in figure 5.

These calibration techniques are done via high-performance coax, waveguide, or on-wafer.

Broadband Calibrations

The list of calibration algorithms is huge. Some popular on-wafer/free space broadband calibration algorithms, which are based on the characteristic’s transmission lines and the delta between two or more of the same type are discussed below. Theses algorithms rely on ideality of the transmission lines, as the various lines must have the same propagation characteristics, impedance, and connector interfaces. Here is a breakdown of each:

· Line-Reflect-Line (LRL) – Sometimes referred to as TRL, its major advantage is that it provides the highest accuracy and has minimal standard definition. It requires very good transmission lines, however, and more care is required because it has less redundancy. It is also band-limited.

· Multiline TRL (mTRL) – It is a highly accurate method with minimal standard definition, as well. One negative of mTRL is that it requires very good transmission lines. It also uses as many as 10 lines and all lines are used at each frequency in a least-square sense, with band limitations. It typically requires more lines than LRL for best performance.

Magnitude and Phase Stability

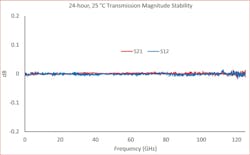

In broadband and mmWave measurements, stability is often of interest because there is the possibility of long measurement sessions or longer calibrations. A long-lasting calibration that reduces the chance of invalid measurements and overall time calibrating is preferred.

The modular BB approach helps achieves these goals by offering advantages. It places the high frequency couplers at the 1 mm (or 0.8 mm) connector to minimize raw directivity degradation. Other benefits are a small integrated package to avoid thermal gradients, and a tightly integrated control system. The result is good stability in reflection and transmission over time, as shown in figure 6.

Measurement Challenges

Once the VNA has been calibrated, measurements can be taken. For passive components, the S-parameter measurements necessary to determine phase are straightforward. One particular application in which measurement of phase/group delay is affected by higher frequencies is materials measurements. Therefore, it is important to know which material category is being tested:

· Insulators (dielectrics) – the energy gap between the valence and conduction band is extreme, so no free electrons are available

· Semiconductors – the energy band gap is smaller, so some electron movement from the valence band to the conduction band can happen

· Conductors – the conduction and valence bands overlap, so electrons can move freely between the valence and conduction bands

Some material measurement methods rely heavily on the change of phase imposed by the material under test. If the VNA is not capable of measuring phase with a higher degree of resolution, the measurement accuracies are highly degraded. Hence, the VNA for making material measurements is very important.

mmWave signals often are at lower power levels than traditional RF or microwave applications. Often, the power requirements for active devices operating at a higher frequency are extremely low, generally -25 dBm or below. Most current VNAs cannot conduct sweeps down to a level of -50/-60 dBm very accurately to +10 dBm, so this measurement is difficult based on specification. However, the Anritsu VectorStar™ VNA-based broadband mmWave system can go beyond -50 dBm with unprecedented accuracies because of the patented NLTL technology in the mmWave modules.

For accurate active device measurements, which demands extremely low input power, how the VNA applies the power to the input of the device is important. A certain level of power handling must be assured or the DUT will be damaged. Certain VNAs, such as the Anritsu VectorStar, have Automatic Level Control (ALC) to assure proper power handling. ALC allows engineers to conduct very accurate power measurements at lower levels and gradually increase it for greater design confidence. An external power meter can also be used for performing power calibrations.

It should also be noted that complete calibration standards are not always available at the end of the VNA fixtures. In these cases, advanced de-embedding and network extraction tools are necessary to achieve repeatable and stable measurements.

Conclusion

Phase has become an important measurement in verifying the new generation of designs that combine mmWave frequencies and small packaging. To ensure repeatable and stable measurements, proper calibration techniques must be instituted, thereby saving time and increasing design confidence.