An Online Tool that Revolutionizes Simulation

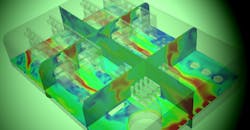

Engineering simulation, also known as CAE (computer-aided engineering), is a technology that allows engineers and designers to assess the performance of their products at any point in the design process via virtual prototyping. Being able to accurately predict the design correctness and efficiency before developing the actual product or building a physical prototype gives more control throughout the product’s lifecycle, and as such, makes the whole design process more cost- and time-efficient (Fig. 1).

1. Temperature distribution on a circuit board and its components.

SimScale is a company that provides simulation support via the internet. I talked with SimScale’s Product Marketing Manager, Milad Mafi, to find out more about the company’s simulation system and the benefits of online delivery.

How can electronics designers and engineers benefit from using simulation?

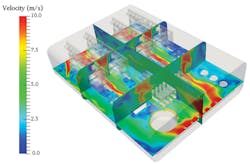

Due to the growing demand for smaller, more powerful devices with increased power densities, effective thermal management has become crucial in the development of electronics, wearables, and IoT designs. With the help of fluid flow and thermal simulation, electronics designers and engineers are able to improve the reliability and efficiency of their products, innovate new solutions, and ensure that they are complying with the necessary safety regulations.

They can achieve that by using simulation for comparing active and passive cooling strategies, finding the right type and placement for fans and heat sinks for a more efficient cooling process, comparing plastic and metal material in terms of which performs better for keeping semiconductors cool, or deciding on the best electronics enclosure dimensions based on the heat flow behavior.

What is preventing simulation from being more widely used in electronics design?

Despite the multiple benefits, until recently, engineering simulation has been inaccessible for the vast majority of SMEs and individual engineers. The reasons mainly being the high software and hardware costs of traditional on-premises CAE software, as well as the complexity of the multiphysics involved. This status quo has been challenged with the emergence of cloud-based, online simulation tools, which are rapidly turning fluid flow and thermal simulations into an industry standard for electronic design.

Milad Mafi, Product Marketing Manager, SimScale

Today, performing the necessary simulation and analyzing the relevant design parameters is no longer the costly and time-consuming task it once was. Instantly accessible via a web browser, without a large initial financial commitment, cloud-based platforms like SimScale have democratized simulation and computer-aided design (CAD).

Do you need to be an expert in order to use simulation?

In the past, simulation technology was mainly reserved for engineering experts, who were able to navigate the complex interfaces and workflows of traditional simulation tools. Many of these tools haven’t changed much in the past 20 years, and still require physics, domain, and tool-specific know-how from the user in order to be able to fully leverage the software.

However, the new generation of simulation tools, like SimScale, is breaking the know-how barrier and making thermal and fluid simulation accessible to every designer and engineer. The intuitive interface, improved solve speed through cloud-based servers, real-time sharing capabilities, and access to dedicated support, learning resources, and consulting services has allowed SimScale to narrow the expertise gap. Today, engineers who have limited prior experience with simulation software can quickly and easily integrate it into their design workflow and start extracting real value from simulation right away.

How accurate are simulation results?

The accuracy and quality of the simulation results mainly depend on the settings and modeling strategies selected by the user.

SimScale is based on cutting-edge, open-source solver technology currently being used by leading companies in a large number of industries with different requirements, such as automotive, aerospace, process technology, and power generation.

Although, in some cases a highly detailed physical prototype may provide more accurate results, in most cases simulation can provide results of an equal accuracy. This has been proven through several validation cases; for example, in one case (click here) SimScale simulation are compared with results to experimental data of heat transfer in a high-power IC package.

In addition, simulation provides a different kind of result. While in a physical test, only the quantities recorded during the test are available for evaluation; simulation provides a complete picture of the flow and temperature field. This enables engineers not only to understand what is happening, but also why it is happening.

What are the advantages and disadvantages of using online simulation vs. on-premises solutions?

The biggest advantage of online simulation is undoubtedly the fact that a technology traditionally reserved for large companies was democratized and thus became accessible to all engineers. This is accompanied by a high degree of flexibility with regard to the use of online simulation tools. The user doesn’t need any dedicated hardware; he can run the simulation on any operating system (including macOS) and doesn’t have to install or maintain any additional software.

Users of traditional, on-premises simulation tools would also appreciate other advantages that are exclusive to online-based solutions. Here, the cloud-based approach to simulation opens up new ways of collaborative work. With colleagues, customers, and suppliers becoming more distributed, collaboration is not an afterthought anymore. Particularly in challenging and complex simulation projects, being able to collaborate effectively with other project stakeholders is important.

Of course, online simulation also has its technological limitations. Although it’s in no way inferior to traditional simulation tools in terms of modeling depth, accuracy of results, and functionality, it does require an internet connection to access the application, while on-premises software can also be used offline.

What makes SimScale unique when compared to other simulation tools?

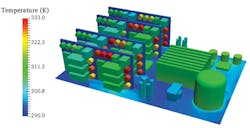

SimScale is the world’s first native cloud engineering simulation platform for CFD, FEA, and thermal simulation (Fig. 2), which is revolutionizing the way engineers and designers develop their products. The SimScale platform is accessible completely via a standard web browser, and with its cost-effective subscription model, is making simulation technology accessible to everyone. Within five years, SimScale became an integral part of the design validation process for thousands of successful companies worldwide and over 100,000 individual users.

2. Forced convection inside the cabinet of an electronic device—the colors represent the local air velocity.

What makes SimScale unique is also it’s real-time consulting support available over chat directly within the workspace, collaboration features, as well as the library of 100,000 public simulation projects that can be leveraged as ready-to-use templates for your own simulation setup.

How can a developer get started using SimScale?

The best way to learn about how SimScale can help you to improve your design workflow, is by checking out the our 30-minute webinar. During this online demo, SimScale’s CEO David Heiny will explain how CFD simulation with SimScale can help engineers better investigate the thermal response of electronic packaging.

There is no prior simulation knowledge required to to attend this webinar. As for the software needed, participants can register for the SimScale Community Plan completely for free. As a cloud-based tool, a PC or laptop and an internet connection are needed.

Milad gained his first experience in the application of engineering simulations at the age of 14. Shortly afterward, he presented his work at various conferences in Europe and the U.S. He is currently working for the German startup company SimScale, having spent five years as a consultant assisting various companies with the integration of simulation technologies.

About the Author

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.