Best of 2015: Wireless System Solves High-Volume Product Test Problems

This file type includes high-resolution graphics and schematics when applicable.

After measuring up all possible candidates for this space, the 2015 BEST communications product was deemed National Instruments’ Wireless Test System (Fig. 1). It addresses the current and growing necessity of testing thousands, even millions, of wireless devices in a fast and cost-effective manner. The system offers a more efficient, flexible, and affordable alternative to traditional automated test equipment (ATE).

As wireless devices like smartphones and embedded modules have grown in volume and complexity, there’s been a corresponding dramatic spike in production test costs. With the sales of smartphones exceeding over one billion per year, test time has become a key manufacturing issue limiting manufacturing output. The multiple wireless features of a smartphone, such as Wi-Fi, Bluetooth, NFC, GPS, and cellular LTE, in addition to 3G technologies, require manufacturers to meet rigid test specifications for each wireless standard—and that takes time. Add in the need to process thousands of devices rapidly, and production costs skyrocket.

While smartphones still present major test challenges, production engineers are now beginning to deal with test volumes that are several orders of magnitude greater, thanks to the emergence of the first Internet of Things (IoT) products. Though these new devices and modules are small and low cost, they include sensors, an embedded controller, and one of many different wireless technologies.

With projections of IoT volumes climbing to 50 billion devices by 2020, test engineers must find a way to speed up testing while lowering costs. Production test costs simply should not be the major factor in IoT product pricing. So, it’s not every day that you get to have your cake and eat it, too. But with NI’s new Wireless Test System (WTS), you get shorter test times and lower costs for any device under test (DUT).

The Genesis of WTS

The WTS derives from NI’s experience with its successful Semiconductor Test System (STS) announced several years ago. The STS is designed to test and characterize integrated circuits in a production environment. The STS is a platform-based approach to testing built with modular PXI hardware, NI’s flagship software LAbVIEW, and NI’s TestStand software. In one application with chipmaker Cirrus Logic, it produced 30% faster testing results and was cheaper than renting a traditional ATE system.

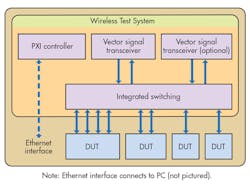

The WTS is a variation of the STS. It uses PXI modules, LabVIEW system design software, and TestStand, which is NI’s test-management and data-analysis software. The resulting system is designed for multi-standard, multi-port, multi-DUT testing for WLAN access points, cellular handsets, infotainment systems and IoT multi-standard devices, including cellular, wireless connectivity, and navigation standards (Fig. 2).

Some of the key enhancements to the WTS include a PXI Express Intel Xeon 8-core embedded controller, a PXI Express 24-GB/s chassis using PCI Express 3.0 technology, and NI’s popular vector signal transceiver.

Features and Specifications

The basic core WTS unit consists of a PXI chassis using the latest and fastest PCI Express bus and an embedded Intel multicore processor. The primary PXI plug-in module is NI’s vector signal transceiver (VST)—a combination wideband vector signal generator, vector signal analyzer, and powerful FPGA (see "PXI and the VST"). The full-duplex RF ports be configured for MIMO, multi-standard, or multi-DUT testing.

The accompanying Wireless Test Module (WTM) provides ready-to-run test sequences for devices from wireless chipset vendors such as Qualcomm and Broadcom. Also included is a Standard Commands for Programmable Instrumentation (SCPI) interface. The SCPI interface, which uses Ethernet, allows for programming of automated test sequences via the PXI-based system.

The WTS can test almost any standard wireless technology. It supports standards such as Wi-Fi 802.11a/b/g/n/ac, Bluetooth and Bluetooth Low Energy, GPS, FM, and RDS, as well as the cellular variations of LTE/LTE-A/HSPA+/WCDMA/TD-SCDMA/CDMA2000/EDGE/GSM.

Other system features include a frequency range of 65 MHz to 6 GHz, up to 200-MHz instantaneous bandwidth, multiplex or broadcast signal switching configurations, and TCXO or OCXO local oscillator options. NI also offers supporting software tools. For example, its chipset vendor tools minimize the need for new test software development.

If you’re planning on developing IoT products in the near future, the WTS could very well be the test solution that best fits the bill, without having to foot an excessive bill.

About the Author

Lou Frenzel

Technical Contributing Editor

Lou Frenzel is a Contributing Technology Editor for Electronic Design Magazine where he writes articles and the blog Communique and other online material on the wireless, networking, and communications sectors. Lou interviews executives and engineers, attends conferences, and researches multiple areas. Lou has been writing in some capacity for ED since 2000.

Lou has 25+ years experience in the electronics industry as an engineer and manager. He has held VP level positions with Heathkit, McGraw Hill, and has 9 years of college teaching experience. Lou holds a bachelor’s degree from the University of Houston and a master’s degree from the University of Maryland. He is author of 28 books on computer and electronic subjects and lives in Bulverde, TX with his wife Joan. His website is www.loufrenzel.com.