Let Software Interoperability Accelerate Your Test Workflow

Test and manufacturing engineers increasingly depend on software to perform their job responsibilities quickly and efficiently. Half of surveyed test engineers, however, specifically mentioned interface/usability as a top characteristic of modern test equipment needing improvement, according to a 2015 test and measurement study by Aspencore (formerly UBM).

Instrumentation vendors have invested in software applications with the goal of making life easier, but the net result is a vast set of disparate software tools that don’t interoperate throughout the software workflow of building, deploying, and maintaining a test system. Throughout the stages of product development, your tools must be designed with interoperability in mind, or you may risk bearing the burden of integration yourself. Time spent wrangling with interoperability issues is time wasted compared to solving actual business challenges and creating product.

To efficiently meet tight schedules, you require not only enough software abstraction to simplify common tasks and enable code reuse, but also enough low-level control at the appropriate stages to achieve detailed, test-specific customization. No single piece of software can perfectly provide both. So, to maximize your engineering design potential, adopt an interoperable platform of software that can provide both.

Over the past four decades, test and manufacturing engineers have adopted National Instruments’ (NI) open, software-centric platform, which is engineered to take advantage of modular hardware and an expansive ecosystem. By reconfiguring hardware in software, engineers have increased the flexibility of their test systems and more quickly translated their ideas into reality.

1. NI software tools interoperate throughout the entire workflow of building, deploying, and maintaining a test system.

NI’s latest version of LabVIEW NXG and recent introduction of SystemLink look to further accelerate development and create efficiencies throughout the entire test workflow (Fig. 1). Although more vendors have embraced the paradigm of software-designed instruments pioneered by the company, this has left engineers struggling to piece together a large set of disparate software tools. However, NI’s tools scale from the I/O pin on an FPGA to remote test system management, thus creating a unique workflow for building a test system.

Designing and Procuring Your Test System

In a world of tight release schedules and demanding project timelines, you must resourcefully tackle the initial design phase for a new test system in a manner that sets your team up for future success. The list of hardware decisions for a new project goes on and on—instrumentation, cables, connectors, switch topology, mass interconnects, rack layout, power budgets, thermal profiling, and so on.

After hardware decisions are finalized to ensure measurement quality, the last thing you need is for software to end up being the bottleneck to your productivity. To help simplify initial system setup, NI developed its Factory Installation Services, which install selected software environments and necessary hardware drivers onto new controllers.

Configuring and Validating Your Setup

Engineering setups often involve instruments from multiple vendors with discrete software capabilities. Paging through user manuals for information on submenu configurations and scouring the web for up-to-date versions of device drivers can get exhausting, especially if the experiences between vendors are inconsistent. Applications developed in software are tightly coupled with their hardware setups, so users need a cohesive management solution that simplifies this fundamental relationship.

2. LabVIEW NXG enables hardware management and system documentation alongside software development.

To this end, the latest version of LabVIEW NXG (Fig. 2) features a new graphical canvas for the visual configuration of physical systems called SystemDesigner. It brings hardware configuration, diagnostics, and system documentation into the LabVIEW NXG environment. The tool manages hardware alongside software development in one environment from start to finish. If an NI or third-party driver isn’t installed, SystemDesigner guides you to install the necessary driver through NI Package Manager, an interface built on industry-standard package formats.

Having conquered the initial setup, your next task is even less straightforward—validate that your product meets all its design requirements. Throughout the test development process, it’s essential to have quick access to interactive measurements like a DMM reading or oscilloscope display for initial testing and debugging of signal connections and verification of measurement accuracy.

In this regard, SystemDesigner launches soft front panels for NI modular instruments to interactively monitor and control hardware. Certain instruments also leverage the direct PC connection to load and store waveforms or device-specific configurations for more convenient debugging. However, to minimize human error, ensure consistency, and ultimately accelerate time to market, automating a significant portion of the validation process is necessary.

Automating Your Instruments

When validating initial circuit boards for a design, chances are high that certain tests will need to be run repeatedly. Performing the same test by hand several times is tedious and, even more importantly from a business standpoint, inefficient.

If an R&D group’s fundamental goal is to fully validate a design and send it to the manufacturing team quickly, the team’s time should be mainly spent focusing on requirements and engineering design tweaks rather than wasting time on logistical tasks that can be automated instead. Once this mindset is adopted, the main barrier is the tests’ creation, given that programming experience among a team of hardware and test engineers can vary widely. The key here is to apply domain expertise without feeling burdened by the semantics and programming constructs of your choice of software.

LabVIEW NXG’s graphical approach to programming lets you program how you think, connecting functional blocks to build the logic of the application. In addition, user-interface (UI) design is streamlined through a drag-and-drop approach that facilitates creation of UIs for test code. The latest version of LabVIEW NXG extends these capabilities to the web as well. No web programming experience is needed to design and deploy web-based UIs that can run test code in any modern web browser without plugins or installers. This new feature, called the LabVIEW NXG Web Module (Fig. 3), makes it possible to monitor and control tests remotely across various devices and operating systems and share information.

3. The LabVIEW NXG Web Module lets you design and deploy web-based UIs that can run test code in any modern web browser without plugins or installers.

Scaling to Production Test

When a product moves from R&D validation to final manufacturing test, it’s crucial to keep device test time low so that total unit throughput is maximized. Instrumentation reuse between design validation and production reduces measurement correlation efforts between these two phases and adds efficiency to the software scaling as well. Independently running the same tests from the device validation phase in the same manner can’t meet manufacturing expectations; the test approach must scale to meet throughput demands.

While much of the same code can and should be repurposed, an abstracted test management tool that sits at the top of the software stack is necessary to combine all relevant, customized tests into a unified test sequence. In addition, it should be able to efficiently test a device, or possibly several devices simultaneously, against its specification limits. Architecting a test executive like this from scratch is extraordinarily cumbersome, though.

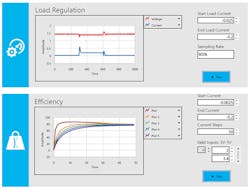

However, a commercial solution like TestStand could help save time with the development effort. TestStand is a ready-to-run test management environment and framework that simplifies the design of a production test system (Fig. 4). TestStand can call code modules written in almost any programming language, allowing the reuse of tests written in G in both LabVIEW NXG and LabVIEW 2017, as well as several others like C, C#, and Python.

4. TestStand addresses cost and efficiency concerns to improve total throughput of a test system.

The environment abstracts the development of test functions like reporting, database logging, and parallel execution, while still allowing for low-level customization when needed. Following a modular software architecture that decouples the test code modules (which are often specific to the device being tested) from the test execution system (which is common to all of the different devices being tested) results in a scalable and flexible architecture that’s less expensive to develop, support, and maintain in the long term. For instance, when characterization and production test software groups at Motorola standardized on a single modular test application based on TestStand and LabVIEW, they reduced combined annual maintenance and new product development costs by more than half.

Deploying and Maintaining Your Testers

Most large test systems aren’t architected in isolation; they represent solutions for multiple test sites or for an entire production floor. After the tests are fully developed, manually deploying the test sequences with all of their necessary dependencies can be logistically challenging. Imagine finally finishing a manual deployment installation on 20 testers, only to find out soon after that you must redeploy a new updated test sequence with one small modification to all 20 again. Now imagine that the number of testers is 1,000.

TestStand simplifies that process using its built-in deployment utility, which deploys the test sequence alongside its code modules and required run-time drivers. You can also use your favorite development environment to create custom operator interfaces (OIs) to deploy with a test sequence. By implementing user credentials, TestStand feature access extends from low-level execution details for software architects to an operator clicking a single Run button on a deployed test station’s custom OI and automatically saving pass/fail results to disk.

5. SystemLink helps manage distributed systems through a central web application.

For large, distributed systems, NI’s SystemLink helps coordinate mass software deployments, manage driver versions across targets, and monitor system diagnostics (Fig. 5). Through a networked connection, a central server node securely manages distributed endpoints and simplifies mass package distribution of both NI and third-party software to target systems, reducing the administrative burden and logistics costs associated with system-management functions.

Software Is the Key

Every company’s product development cycle will have its niche quirks. Many will repeat the product validation phase many times to reach an inflection point that warrants production, perhaps being forced to revisit design and configuration along the way. Meanwhile, some startups may never reach full-scale deployment of production testers based on product forecast alone. After all, if every company’s development cycle was identical and 100% successful every time, how would the market sustain a dynamic sense of competition?

Electronics designers and manufacturers must adopt a platform of tools that enables healthy course correction when a product suddenly adds a feature or raises a spec to stay competitive. While we all, of course, will try to be as proactive as we can early in the product development cycle, reality demands that we remain nimble. As engineers, we’ve already signed up for this challenge, and can’t let our tools become our bottleneck.

To that end, LabVIEW NXG, TestStand, and SystemLink software accompanies you throughout the entire workflow of building, deploying, and maintaining a test system. Let software interoperability accelerate your workflow—it’s the smarter approach to test.