Members can download this article in PDF format.

Just like Goldilocks, the market for advanced driver-assistance systems (ADAS) and in-vehicle infotainment (IVI products) knows when something is just right. And when it comes to getting it right, it’s hard to argue against bulk-acoustic-wave (BAW) clocks in applications requiring timing and reliable clocking circuits.

Sponsored Resources

- Beyond Quartz: How BAW Clocks Are Redefining ADAS and IVI

- Automotive, Low-Power, Fixed-Frequency LVCMOS Oscillator

- Bulk Acoustic Wave (BAW) Based, Reference-Less Clock Generator

BAW is a resonator technology that uses piezoelectric transduction to generate a gigahertz frequency and high-Q resonance that can be integrated directly into standard plastic packages. A high Q value indicates low damping and energy loss at a lower rate.

Advantages of BAW over traditional quartz and microelectromechanical resonators include streamlined manufacturability, improved flexibility, better frequency stability, and ultra-low jitter, as well as enhanced reliability under harsh environmental conditions such as vibration and shock.

Also, for ADAS and IVI systems, support for Peripheral Component Interconnect Express (PCIe) is crucial. It’s an industry standard for transferring data between CPUs and peripheral devices across motherboards. Both frequency- and time-domain specifications must be met to be compliant to PCIe.

In PCIe systems, both the transmitter and receiver devices are provided with a reference clock. To increase bandwidth and performance, automakers are implementing the PCIe 6.0 specification, which doubles the data rate to 64 GT/s and enables up to 256 GB/s for x16 configurations.

BAW Clocks: Accurate and Safe

By maintaining ±25-ppm stability over 10 years, BAW clocks provide precision over system lifetimes, reducing the risk of frequency drift that can affect sensor accuracy. In addition, a <3-ms startup time—quartz is traditionally <6 ms—improves real-time vision analysis and response times to support ADAS functions with greater distance detection, sensor fusion, and faster processing.

What’s more, zone architectures increase clock-tree complexity. BAW clocks can reduce board space by as much as 55% compared to quartz, while helping designers meet functional-safety requirements.

BAW technology also is functional-safety-capable, helping designers meet Automotive Safety Integrity Level (ASIL) D standards with a lower failure-in-time (FIT) rate compared to quartz. As a result, it provides longer-term reliability in ADAS, IVI, and radar and LiDAR systems. FIT rate measures the expected failure per billion hours of operation.

Designers can simplify their systems by reducing the number of clocks in a complex IVI platform. The integrated BAW resonator in Texas Instruments’ LMK3H0102-Q1 clock generator (with low-power high-speed current-steering logic outputs) and the LMK3C0105-Q1 low-voltage complementary metal-oxide semiconductor (CMOS) clock generator eliminate the need for an external clock.

Industry's First Automotive BAW-Based Clocks

Electronics in ADAS and IVI systems must work reliably while facing temperature fluctuations, vibrations, and electromagnetic interference. With TI's BAW technology benefits, the new CDC6C-Q1 oscillator and LMK3H0102-Q1 and LMK3C0105-Q1 clock generators increase reliability by 100X compared to traditional quartz-based clocks, with a FIT rate of 0.3. Enhanced clocking precision and resilience in harsh conditions enable safer operation, cleaner data communication, and higher-speed data processing across next-generation vehicle subsystems.

In addition, the current and next generation of automobiles demand high-performance processing for ADAS and in-vehicle infotainment systems. These trends require precise and reliable clocks to enable processing and high-speed data transfer across the vehicle. Functional-safety-capable BAW clocks target embedded processing high-performance computing (HPC) systems that combine ADAS and IVI domains, where sensor input from camera, radar, and LiDAR systems help protect drivers and passengers.

TI’s high-performance BAW clocks feature high reliability compared to quartz technology for ADAS and IVI processing timing needs. They make it possible to meet functional-safety requirements and reduce board space by as much as 55%, all backed by a reliable supply chain with second-source capability.

Key Features of the CDC6Cx-Q1 and LMK3H0102-Q1

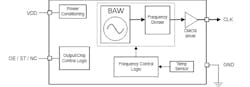

The CDC6Cx-Q1 automotive, low-power, low-ppm, low-jitter, fixed-frequency LVCMOS oscillator incorporates BAW as the resonator source (see figure). The device is factory-programmed per specific frequency and function pins. With a frequency control logic and output frequency divider, the CDC6Cx-Q1 is capable of producing any frequency within the specified range, providing a single device family for all frequency needs.

TI’s LMK3H0102-Q1 is a two-output PCIe Gen 1 to Gen 6 compliant, reference-less, clock generator with spread spectrum clocking (SSC) support. SSC generation or “dithering” (modulating the clock frequency) is the process by which the system clock is dithered in a controlled manner so as to reduce peak energy content. If you transform a clock signal to the frequency domain, there will be a high energy spike at the frequency of the clock. Spread spectrum is a way to distribute this spike over a band of frequencies to reduce the power at the frequency of the signal.

Based on TI’s proprietary BAW technology, LMK3H0102-Q1 provides ±25-ppm clock outputs without any crystal or external clock reference. These devices can offer two SSC clocks, two non-SSC clocks, or one SSC clock and one non-SSC clock simultaneously. The LMK3H0102 meets full PCIe compliance from Gen 1 to Gen 6.

TI also offers the LMK3H0102EVM evaluation module (EVM). It provides a complete clocking platform to evaluate the clock performance, pin configuration, software configuration, and features of the LMK3H0102.

In summary, while quartz has difficulty meeting long-term reliability, vibration resistance, and timing requirements, BAW clocks offer very low jitter and enhanced reliability and performance, enabling safer operation, cleaner data communications, and faster processing. And with a low FIT rate, resilience to harsh conditions, and precise clocking capability, TI’s BAW clocks provide a more reliable and efficient solution for subsystems across the vehicle.

Sponsored Resources

- Beyond Quartz: How BAW Clocks Are Redefining ADAS and IVI

- Automotive, Low-Power, Fixed-Frequency LVCMOS Oscillator

- Bulk Acoustic Wave (BAW) Based, Reference-Less Clock Generator