Members can download this article in PDF format.

The quest to develop consumer products that are more reliable, efficient, and cost competitive is never-ending. While progress is made across all design vectors, perhaps the most visible is the microcontroller (MCU). From its early beginnings with the TI 1000 to the latest generation of C2000 and F28E120SC real-time MCUs, it has certainly come into the limelight to address today’s competitive, cost-sensitive consumer markets.

Engineers have always been tasked with making the most with the least, and as economically as possible. Early designs generally focused on circuits to add features, i.e., single-task, purpose-built circuits interfaced between the MCU and motor.

While these circuits add features, they also introduce tangential (synchronization, parasitics, spurious signals) issues. These individual solutions also added extra costs. So, designers began to look at how to replace this disaggregation with integrated electronic devices, particularly the MCU.

Sponsored Resources:

- Smoother, Quieter Motor Performance with Real-time MCUs

- Achieve Seamless Motor Control with TI's Real-time MCU Portfolio

- Create Next-generation Appliances and Power Tools with TI

A Brief Look Backward

Let’s take a quick trip down memory lane to one of the first MCUs, the TI 1000. This chip integrated three basic circuits: RAM, ROM, and a clock.

Referring to Figure 1, it can be seen that external motor-control devices or circuits are interfaced to the I/O ports (K, O), and each would be a separate specific function circuit or device. Here, the MCU simply receives and sends signals to the peripheral control circuits via the ports.

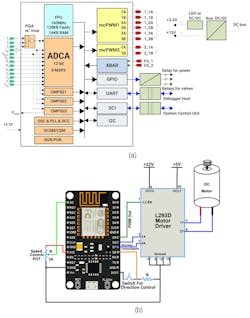

Figure 2a shows a diagram of a modern MCU capable of field-oriented control (FOC). Figure 2b is the same practical circuit with dedicated circuits for motor control.

Fast Forward to Today

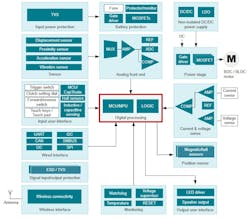

Modern MCUs have evolved into complex, multifunction devices with a slew of embedded functions, components, and circuits. They’re a unified environment controller that moves the peripheral device control from separate circuits directly to MCU (Fig. 3). Such circuits include integrated programmable gain amplifiers, high-speed analog-to-digital and back converters (ADCs/DACs), comparators, wireless radios, timers and counters, peripheral interface controllers (PICs), and more.

This creates a cohesive processing framework, eliminating much, if not all, of the interface noise and parasitics that come with individual module or circuit interconnects.

The consumer power tool market has seen many benefits from the integrated MCU approach. As mentioned earlier, this market is cost-sensitive. Thus, consolidation of control to an MCU, eliminating the cost of many peripheral components, is a primary driver. Additional benefits come from improving performance. Modern MCU-controlled tools and appliances run more reliably, are more durable, and have lower failure rates.

Field-Oriented Control: The Great Enabler

Perhaps the most beneficial development in motor control comes from field-oriented control (also called vector control). FOC of motors brings about a slew of improvements in both simplified design and operation.

For example, FOC optimizes torque by aligning the magnetic fields of the stator and rotor. This has multiple benefits. First, it minimizes the need for high current and torque with separate circuits. This results in less torque ripple and enhanced operational smoothness.

Alignment is beneficial in other ways as well:

- Better torque delivery due to stator and rotor alignment.

- Reduced vibration and noise are realized since magnetic misalignment can create torque ripple, leading to vibrations and acoustic noise.

- Lower heat generation because misaligned fields waste energy. This is dissipated as heat.

- Aligning fields improves the power factor, reducing reactive power demand from the grid.

- Reduces heating; extends insulation and bearing life.

- Alignment smooths output, making the motor quieter and more stable.

Another benefit of FOC is its ability to regulate the current in the stator windings, Field-oriented control reduces back electromotive force (EMF), a contributor to noise and vibration. It leads to a more subdued motor performance and less wear and tear. This is a particularly important benefit for consumer power tools and appliances.

Furthermore, with FOC, a technique called field weakening can be implemented. This is where the effective rotor magnetic field is reduced by controlling the current, allowing the motor to run at higher speeds without sacrificing torque. The technique is particularly beneficial in applications where noise and vibration must be minimized.

Practical Applications

The benefits of FOC are significant with large household appliances and HVAC. HVAC systems have powerful motors that are loud and vibrate, especially during the transition periods. Because these are higher-power systems, unwanted parasitics are very noticeable.

For such systems, FOC motor control is just what the doctor ordered. It regulates brushless HVAC motors via separate management of torque and magnetic flux. FOC separates these two elements of an AC motor’s stator current by converting the three-phase stationary reference frame into a two-axis rotating reference frame. This also has the benefit of enhancing torque because it aligns the stator and rotor magnetic fields, which reduces surges.

Major appliances such as washers are now complex, multifunction high-tech devices that have a slew of functions and operational modes. For example, they feature multiple speeds, multiple wash stages, and specialized care programs. These cause the motor to run in a number of states, which creates non-linear stress conditions, potentially leading to sudden load imbalances. Open-loop startup and multi-cycle operational modes require the motor to start, stop, and run according to a program, or react to error conditions.

They must also manage vibration. This can be economically accomplished with direct software-driven, sensorless motor control. The result is much smoother and quieter operation with less design complexity, and better reliability.