Improve the Sustainability of Electrified Utility Vehicles with Advanced Battery Charging

What you'll learn:

Industrial sectors are at a crossroads. Two driving market forces — rapid urbanization and government regulations — demand innovative solutions that balance the need for expansion with a commitment to sustainability.

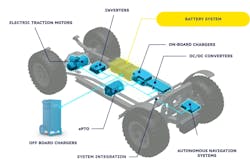

To meet these growing pressures, hybrid and battery-powered mobile elevated work platforms (MEWPs) emerge as the logical solution. Operating with zero emissions, reduced noise, and lower total cost of ownership (TCO), electric MEWPs present an attractive option for fleet owners and OEMs alike (Fig. 1).

Advanced battery charging solutions are central to the success of these electrified MEWPs. Optimized systems cut charging costs by 46.3%, while integrated, modular designs address key electrification challenges, such as range anxiety and limited charging options.

With MEWP demand surging, electrified machinery is set to fill the gap — and charging solutions have a critical role to play.

The Role of Battery Technologies in MEWPs

Lead-acid batteries paved the way for electrification in early MEWPs and continue to offer cost-effective, sustainable solutions. Thin-plate pure-lead (TPPL) batteries, for example, provide up to 99% recyclability, retaining the benefits of lead-acid technology without environmental drawbacks.

The advent of lithium batteries further revolutionized electric machinery, delivering substantial improvements over lead-acid alternatives. Some of these advantages include:

- Improved power density, supporting longer operational hours and heavier loads

- Superior longevity, reducing the frequency of replacements (and associated costs)

- 40% lower TCO, minimizing long-term operational expenses

These advances come without sacrificing sustainability. Readily available recycling options, such as Redwood Materials’ patented hydrometallurgy process, can recover over 95% of lithium from spent batteries, as well as nickel, cobalt, and other valuable materials used in their construction.

As battery technology matures, the spotlight shifts to other aspects of the drivetrain. OEMs must take a holistic view to achieve maximum value from the battery, which absorbs up to 50% of an electric MEWP’s total cost (Fig. 2).

Put simply, protecting the battery means using the right charger.

The Criticality of Advanced Battery Charging Solutions

How can OEMs identify the “right” charger for their machinery? Not all solutions are universally compatible. Modern chargers must match both battery chemistry and the machinery’s intended application.

For example, high-frequency chargers require specially programmed charge curves — a sequence of algorithms that deliver power in three phases to ensure battery safety and minimize recharge time.

>>Download the PDF of this article, and check out the TechXchange for similar articles and videos

The diversity of applications within the MEWP sector adds another layer of complexity. Power requirements vary significantly across different equipment types:

- High continuous power: Articulating boom lifts require sustained energy output to handle extended operations and demanding workloads.

- Low power: Warehouse scissor lifts or stationary vertical lifts need less intensive energy delivery for intermittent or low-intensity use cases.

- Balanced power: Rough-terrain scissors or mast lifts need a moderate power balance to manage varied terrain and medium-duty cycles.

- Voltage operating requirements: These machines have different voltage requirements, with lower-power scissors and higher-power booms typically using 24- and 48-V systems, respectively.

These varied power demands and duty cycles require chargers to be versatile enough to preserve battery health, enhance efficiency, and minimize downtime.

4 Ways Charging Solutions Enhance Efficiency and Sustainability

Far from simply supplementing the battery, charging solutions are integral to the electric MEWP ecosystem. Consider four ways chargers contribute to the machinery’s overall value.

1. Telematics and IoT integrations

Onboard chargers equipped with telematics capabilities empower OEMs and fleet managers with tools to monitor and manage MEWPs remotely. These systems offer strategic visibility into key parameters such as:

- Real-time battery health

- Vehicle usage patterns

- Charging efficiency

Such smart charging systems safeguard battery health while logging critical data, which is valuable for predictive maintenance, first-in-first-out queuing, and similar operational strategies. Duty-cycle data can also be leveraged to tailor charging strategies that meet the high demands of MEWP applications.

2. Advanced safety features

Electrified machinery innately enhances safety and operator comfort by eliminating the toxic emissions, excessive noise, and uncomfortable vibrations often associated with traditional MEWPs.

Chargers contribute by negotiating safe grid-to-machine energy transfer, immediately cutting off power in the case of abnormalities. In integrated systems that combine charging and drive electronics, this shared power infrastructure supports auxiliary functions critical to operator safety, such as:

- Collision-avoidance detectors

- Load-sensing systems

- Regenerative brakes

The charger doesn’t directly “power” these systems. Its role as a bidirectional DC-DC converter allows it to efficiently manage power flow — for auxiliary systems while the vehicle is stopped, and between the battery and motor (to support regenerative braking) while the vehicle is in motion.

3. Eliminating internal combustion

The act of “refueling” an electric MEWP is inherently more efficient and sustainable than an internal combustion engine (ICE). With electric energy available at stable (and far lower) prices than volatile fossil fuels, electrified MEWPs enjoy a lower TCO while complying with the ever-tightening regulatory standards surrounding CO2 emissions. With no need for oil changes, maintenance demands are reduced, as are the risks of environmentally hazardous oil spills.

4. Enabling faster charging

Electrified MEWPs, particularly those powered by lead-acid batteries, have long struggled with prohibitive charge times. The introduction of DC fast chargers changed this — drastically reducing recharge time from an average of 4 to 10 hours to as little as 20 to 60 minutes. As charging infrastructure expands globally, operators and OEMs can leverage these advances to maintain efficient, sustainable operations.

Best Design Practices for Electric MEWPs

The implications of the above features directly influence best design practices in electric MEWPs. Note these design considerations:

Modularity

A design principle wherein chargers can be “stacked” to enhance power delivery, modularity allows for:

- Reduced downtime

- More scalable operations

- Simplified system repairs and upgrades

This flexibility applies to both onboard and offboard charging solutions, allowing OEMs to adapt to the specific needs of their fleet or application.

48-V auxiliary power

While many electrified machines currently operate between 12 to 24 V, OEMs who opt for 48-V setups future-proof their MEWPs, aligning with the industry trend toward higher-power solutions.

Electric power takeoff (ePTO)

Hybrid machinery equipped with ePTO runs auxiliary systems directly from the battery rather than the engine. This enables auxiliary functions even when the engine is off, reducing emissions and operational noise while powering systems such as:

- Hydraulic pumps for boom and lift operations

- Lighting and climate-control systems

- Electric winches and hoists

Supporting ePTO functionality demands that the battery pack (and broader electrical infrastructure) meet specific requirements — namely, sizing. While hybrid architectures often leverage smaller batteries and electric motors, both must deliver voltages sufficient enough to power heavy auxiliary equipment, such as a hydraulic boom’s 48-V DC load.

The All-Electric Future of Access Equipment

Electrification trends also reveal promising opportunities for future MEWP applications, particularly in areas where technology and sustainability converge.

For example, AI and automation may help address labor shortages while also meeting the surging demands of e-commerce. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), including automated forklifts, are already being deployed in predictable warehouse settings, demonstrating the viability of such technologies.

Operators likewise experiment with virtual reality (VR) and augmented reality (AR), both for training and remote operation.

How will these advance, powered and sustained by electrification, affect battery design? Several needs emerge:

- Higher energy density to power propulsion and auxiliary functions without losing uptime.

- Precise energy management to balance load, thermal regulation, and ongoing battery health.

- Robust safety features to protect against thermal runaway, overcharging, and other hazards.

As industrial sectors grow increasingly autonomous, these functions will prove essential for smooth automated operations with less direct oversight.

Charging Solutions: Driving More Efficient MEWPs

Demand for electrified MEWPs will only continue to grow. However, to fully realize the value of these machines, OEMs must adopt a holistic approach to system design. Chargers are a fundamental consideration, influenced by factors such as battery chemistry, application-specific needs, and level of integration.

Electrified MEWP designs are trending toward higher power capabilities, driving the adoption of systems with increased auxiliary voltages, effective ePTO, and modular charging solutions. Embracing these enhancements and developing future-proofed architectures will undoubtedly prove a competitive distinction in the coming years.

As adjacent industries inspire and inform new MEWP designs, the innovations born from this demand may, in turn, reshape other sectors.

References

JLG, “2022 MEWP Industry Trends.”

Science Direct, “Optimization of Charging Schedule for Battery Electric Vehicles Using DC Fast Charging Stations.”

Redwood Materials, “Building the most sustainable (and scalable) battery materials process.”

Machine Design, “Moving a New Machine to Electric Drive.”

Zivan, “Charge Curves.”

OEM Off-Highway, “Leveraging Advanced Charging Technologies for Off-Highway Vehicle Electrification.”

Work Truck, “What’s an ePTO?”

IAS, “Bidirectional integrated on-board chargers for electric vehicles—a review.”

>>Download the PDF of this article, and check out the TechXchange for similar articles and videos

About the Author

Kyle Franson

OEM Account Manager, North America, Delta-Q Technologies

Kyle Franson is an OEM Account Manager, North America at Delta-Q Technologies, a ZAPI GROUP company. He’s based in Denver, Colo., and reports to the company headquarters in Vancouver, Canada. He has over eight years of technical sales experience in industries ranging from electric vehicles, robotics, and energy markets to contract manufacturing.

Kyle uses his combination of technical sales and project management experience to help global OEMs of off-highway vehicles and industrial machines develop and launch new electric-drive machines. Through established relationships and collaboration with battery manufacturers, distributors, OEMs, ancillary components suppliers, and other industry experts, he’s a thought leader on global electrification trends.