Q&A: The Latest Trends Stirring Up USB 3.0

This file type includes high-resolution graphics and schematics when applicable.

has been in play with USB since its inception, and continues in that regard as the advent of USB 3 pushes the bounds of USB support. I spoke with Chee Ee Lee, Head of Product Development for FTDI Chip, about USB 3 trends and what’s in store from the company.

Wong: What are the key benefits of using USB 3.0?

Lee: Well, the USB 3.0 SuperSpeed standard effectively enables an order of magnitude improvement on USB 2.0 data rates, but with the plug-and-play connectivity that engineers are already very familiar with from other USB generations (which made the standard appealing in the first place).

Thanks to the much higher data-transfer capacity—it affords up to 5 Gbits/s via a full duplex I/O structure—engineers will be able to tackle far more data-intensive applications than previously possible. Power delivery has been scaled up, too, allowing access to 100 W (as opposed to the 10 W of the preceding generation). Backward-compatibility with older USB incarnations means that upgrading of legacy equipment to USB 3.0 is simple and cost-effective to accomplish. Finally, the smaller form-factor connectors are highly optimized for modern space-limited designs.

Wong: The standard has been around for quite a while. So why hasn’t it made an impact on embedded-systems design until now?

Lee: Originally, other elements within the system were not able to keep pace, and these would have just resulted in bottlenecks. There is little point migrating to higher-speed interconnect technologies if the benefits cannot be seen over the system as a whole. As speeds have increased in other elements of system designs (sensors, memories, etc.), the argument for moving to USB 3.0 has become more compelling. Operating-system (OS) support also held things back to some degree.

This meant that though USB 3.0 has seen relatively strong uptake in the consumer market over the last few years, with tablet and laptop products incorporating it, there was little traction in the embedded space during this time. With the advent of a broader range of OS support (in particular from Linux and Windows 10), all of this has started to change very rapidly.

Wong: So now that the OS support issue has been resolved, is USB 3.0 set to be commonplace in embedded-system design?

Lee: Well, the potential is undoubtedly there, but other challenges still must be overcome. These are manifesting themselves both technically and financially.

Wong: What do you see as the most important applications for USB 3.0 technology in the next few years?

Lee: The use of USB 3.0 to carry out bulk transfer of data to external storage devices is clearly a very important one. Another will be the growing need, across a broad cross-section of industry sectors, to exploit high-definition video content. Among the key areas where this is certain to have value will be advanced machine-vision systems, surveillance equipment, digital signage, medical imaging, industrial data logging, and point-of-sale (PoS) units. We at FTDI Chip already see numerous examples that are garnering customer interest. These include:

• Monitoring of fluid as they flow through pipelines, with data being acquired to ensure against any leak or blockage problems.

• Video imaging in scenarios such as security/building access systems. The transfer of higher-quality video content is now being mandated here. Because USB 3.0 can support 1920- × 1080-pixel resolution video at speeds of 120 Hz, it offers more than adequate bandwidth for such purposes. HD image data can be displayed at frame rates that will permit smooth video playback without lag or distortion issues.

• Environmental sensing systems for examining potentially harmful airborne chemical compound levels, to ensure that safety thresholds are not exceeded.

• Factory production lines, given that machine vision has developed a lot in the last few years. Demand is increasing for more detailed images to be captured and, as a result, higher-resolution sensors are being procured. These subsequently need higher-speed data interfaces to accompany them. Through these more sophisticated systems, it’s possible to meet quality control targets and heighten throughput levels.

• 3D imaging, with banks of cameras simultaneously taking pictures from multiple angles. The acquired data can be used in immersive gaming or, alternatively, for body imaging to facilitate the fitting of prosthetic limbs.

• Traffic-monitoring systems. Here, the greater image clarity that can be brought about by high-resolution image sensors, complemented by USB 3.0 interfacing, will go into cameras positioned on road junctions, etc. These imaging systems will then be able to pick up on traffic violations and identify the vehicle number plates so that those responsible can be fined/prosecuted.

Wong: Which interface standards are going to be its rivals in these types of applications, and what would you say will give it the edge over them?

Lee: For many of the applications just discussed, the main competition for USB 3.0 will be FireWire, HDMI, Ethernet, and CameraLink. From a speed perspective, it can outperform Ethernet, FireWire, and CameraLink, while having much greater versatility than HDMI. The fact that data and power can be supplied through just one cable is another important advantage that must be considered. This means that USB 3.0 camera-system deployments, for instance, are simpler and less expensive, and take up less space.

Wong: What are the challenges you see with implementation of USB 3.0 technology in the short/medium term?

Lee: Though, as already discussed, there are great prospects for USB 3.0 deployment, the semiconductor industry needs to be able to offer IC solutions that fully recognize the pressures that engineers are under. Currently, a large proportion of the ICs available are unable to do that, because the majority of USB 3.0 ICs serving the embedded sector are based on microcontroller architectures.

This has a number of major implications, leading to higher system costs and greater use of available engineering resources. With the microcontroller approach, it is necessary to create, compile, and debug substantial quantities of code. This takes both time and considerable expertise to do. Furthermore, the microcontroller cores on which these ICs rely push up the unit costs, as well as take up valuable board real estate and increase the overall power budget.

Wong: So what is the alternative to a microcontroller approach?

Lee: Many people now have the opinion that hardwired solutions, rather than microcontroller solutions, are going to be the most attractive way to accomplish USB 3.0 deployment in a fully effective manner.

At FTDI Chip, we certainly uphold this view. It is clear that employing a microcontroller-based architecture for USB 3.0 is simply not efficient. The programmability aspect is something that in most cases is not actually required and it just adds to the overhead, leading to unnecessarily wasted development time, increased power consumption, occupied PCB space, etc.

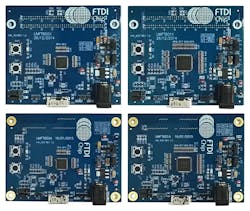

Instead, engineers need a way of adding USB 3.0 technology to their systems to take care of budgetary, power, and space constraints. The ICs in our recently introduced FT60X series of USB 3.0 interface devices each feature a proprietary, hardwired, 32-bit processing core (running at 100 MHz). This is much more streamlined than the microcontroller solutions just discussed. In the end, it avoids having to create and debug masses of code, keeps development times brief, and brings bill-of-materials costs down to more acceptable levels.

About the Author

Chee Ee Lee

Head of Product Development

Chee Ee Lee is Head of Product Development for FTDI Chip. Based in Singapore, he oversees all of the company’s projects to create new ICs, as well as the supporting hardware and software that will accompany them. He has worked for the company for five years, and has over two decades’ worth of industry experience behind him. Prior to joining FTDI Chip, he worked for ST-Ericsson, ST-NXP, and Philips Semiconductors.

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.