This file type includes high resolution graphics and schematics.

Consumers don’t have to look beyond their Amazon Kindle or Barnes & Noble nook to find examples of electronic paper. But electrophoretic displays are appearing in more and more applications beyond these popular e-readers. They’re being used in hundreds of applications because the technology lets designers create low-power, flexible displays in unique shapes and sizes using durable plastic substrates instead of glass.

Related Articles

Electrophoretic technology gives designers the freedom to put displays into applications they never before thought possible. This versatile technology is also eco-friendly, boasting low power consumption. It offers a thin and lightweight design, a low electromagnetic interference (EMI) profile, and a wide viewing angle as well. It’s one of the most reliable display technologies on the market, and embedded system designers are adding several million of them to the tens of millions already available in new applications each year.

How It Works

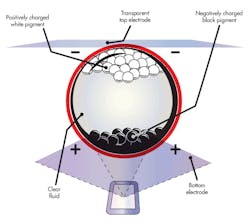

Electrophoretic displays are based on the principle of electrophoresis, which explains the motion of charged particles in a fluid under the influence of an electric field. The principal component is the microcapsule (or microcup), and there are millions of them in each display. Each microcapsule contains a mixture of positively charged black particles and negatively charged white particles suspended in oil. When a positive or negative electric field is applied, corresponding particles move to the top of the microcapsule, where they become visible to the user. The surface then appears white or black at that spot.

To produce a flexible electrophoretic imaging film, the capsules are suspended in a fluid and coated onto a flexible plastic substrate in an efficient roll-to-roll process (Fig. 1). Averaging less than 50 µm in diameter, the capsules are packed together tightly on the finished film, lending it the appearance of paper.

Creative Flexibility

Consumer electronics companies spend millions on branding, product design, and packaging, yet most consumer electronics end up with the same, traditional rectangular display. In an age when the user interface is an increasingly important differentiating factor when consumers are deciding between a sea of products that offer the same capabilities, a unique display can dramatically increase consumer appeal. Just think about the current smart-phone offerings where the only differentiators are style and design, i.e., the user interface.

With the versatility that electrophoretic displays provide, you can design a display around the product, rather than create a product around the display. These displays can be round, triangular, or mounted on a curved surface, or they can even resemble a logo. The possibilities are only limited by the designer’s imagination. For example, Central Standard Timing’s CST-01 watch uses a flexible display (Fig. 2). And with no need for a glass backplane, the display surface itself doesn’t even need to be flat. Electrophoretic displays can enhance the design and functionality of many handheld devices, including automotive key fobs, wristwatches, and remote controls.

Appearance

Anyone who has ever tried to work on a laptop while at an outdoor café, read with a backlit tablet on the beach, or use a digital camera on a sunny afternoon understands the inherent obstacles of traditional backlight displays. These displays perform optimally indoors with appropriate lighting, but that isn’t always the usage reality for consumers. That’s why backlit displays, like LCDs, are often associated with eyestrain.

Electrophoretic displays allow users to read for hours without suffering from the same level of fatigue experienced with LCD technology. Plus, electrophoretic displays function just as well indoors and outside, offering a paper-like appearance that is easy to read in the noonday sun while remaining well lit in the shade.

Bendable, Rugged, And Low Power

Due to their high levels of durability and flexibility, electrophoretic displays will allow any object to become “smart.” Just imagine a future where displays are built right into your clothing or handbags. These displays are ideal for new and upcoming technologies like smart cards, which need to hold up to being jammed into tight wallets, sat on, tossed on the counter, or even dropped.

With a long life span, electrophoretic displays are ultra-thin, won’t shatter, and will keep functioning as long as the device itself. For example, an e-paper display could show the controls and power settings of a power drill (Fig. 3). With more than 20 million flexible displays performing successfully in the market today, it is clear that electrophoretic displays are the right technology for applications where wear and tear is a factor since the technology has the inherent flexibility and ruggedness of paper.

Battery life and power consumption factor considerably into consumer purchasing decisions. A 2012 Qualcomm study found that battery life ranked second behind price in smart-phone purchases—and that’s just one application. Electrophoretic displays are highly reflective and therefore consume a fraction of the power that traditional backlight displays use. This property extends the battery life of devices using electrophoretic display technology, including smart phones, smart cards, and electronic shelf labels, sometimes up to 30 times longer than a device using the same battery with a traditional backlight display.

Lightweight

Electrophoretic displays are roughly as thick as six sheets of traditional paper (650 µm), which, when combined with their low power consumption, can reduce the size and weight of a device as well as its batteries. Ideal for applications where the weight and thickness of the display and its components are critical, an electrophoretic display’s lightweight properties make it ideal for portable electronics.

In addition to the space-saving benefits, these lightweight displays also enable new technologies, such as large secondary displays that blend into a design, similar to those that can make the keypad in mobile phones and laptops changeable. These changeable keypads can be used to automatically change letters to numbers or symbols depending on how the phone is being used at any particular moment, a process that consumers are beginning to expect from their mobile devices (Fig. 4).

What’s Next

Flexible electrophoretic displays have been in mass production for the past several years and have been designed into many devices. However, only a few designers have taken advantage of all the features of this display technology, in particular the ability to shape the display around the device. Moving forward, with the increased consumer demand for smart, lightweight technologies, we expect the use of microcapsule-based electrophoretic displays to grow exponentially.

Sriram Peruvemba is an executive advisor at E Ink Holdings, CMO of Cambrios Technologies, and executive advisor to YFYJupiter. Previously, he held senior positions at Sharp Corp., TFS Inc., Planar Systems, and Suntronic Technology.

This file type includes high resolution graphics and schematics.

About the Author

Sri Peruvemba

CEO, Marketer International Inc.

Peruvemba, the CEO of Marketer International, has served on the Executive Board and was former Chair of Marketing for many years for the Society for Information Display (SID). With over 30 years of experience in the technology industry, Peruvemba has been an influential advocate in the advancement of electronic hardware technologies. He’s an acknowledged expert on sensors, electronic displays, haptics, touchscreens, electronic materials, and related technologies; and consults, writes, and presents on those subjects globally.