Interview: The Iron Man of Maine at Maker Faire NY 2013

Elon Musk might be considered by some to be the real-life Tony Stark, but Thomas Lemieux is giving him a run for his money as the real-life Iron Man. Lemieux took his interest in electronics and made his own replica Iron Man suit, complete with working components. Although it may not be able to fly, attendees of the 2013 Maker Faire in New York couldn’t help but be impressed by what the Iron Man of Maine had accomplished in his basement. I got to ask the man behind the mask a few questions.

Sokol: What inspired you to make the suit?

Lemieux: I've always been inspired by robotics, electronics, art, and superheroes. I'm a fine art and graphic design major and wanted to combine all of my talents together.

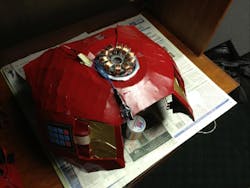

Made primarily of foam and plastic that is spray-painted to look like the suit in the latest Avengers movie, the electronic components are housed in Altoids tins placed in the shoulders and chest of the suit.

Sokol: How did you design the “arc reactor” for the chest piece?

Lemieux: The whole project started with the arc reactor. I wanted one to sit on my desk at home and thought it would be cool to build one myself. So I walked the aisles at Home Depot and found any part that would seem to work. The fins are cut from a solid sheet of metal and I used copper coils to bend around them. I used a sink tap as the center piece. And the rest is washers, rubber tubing and erector set pieces all J-B welded together. I got all of the electronics and LEDs from Radio Shack.

The suit contains bionic repulsors in the hands, and although they can’t actually blast enemies away, all Lemieux has to do is flex for the LEDs to light up and for the sound effects to start up.

Sokol: Can you tell us about the biometric circuit you designed for the hand piece?

Lemieux: The bionic repulsors use a muscle sensor chip that I purchased from Advancer Technologies. They have a whole tutorial on how to make the circuit using EKG sensors.

Sokol: How did you build the sound components for the suit?

Lemieux: The sound components for each repulsor and the sound board are wave shields from Adafruit. The SD cards with all of the sound files are located there.

Sokol: How is the suit powered?

Lemieux: Everything is Arduino powered. There are four Arduino UNOs in the suit; one for each bionic replusor, one for the sound board, and one for the arc reactor. All of the components are powered by ten 2600 mAh batteries that had to be ordered from Hong Kong.

Sokol: What was the biggest design challenge you faced while building?

Lemieux: The biggest challenge was getting all the electronics to fit in the suit and to make the suit fit on me just right. It was very much trial and error.

Sokol: How long did it take you to complete building the suit?

Lemieux: I started building on May 2nd, spending about four hours a day plus many all-nighters.

Sokol: What was your favorite part of being at the Maker Faire?

Lemieux: My favorite part was all of the 3D printing and robotics, I just wish I could have taken the time to see more of it.

Sokol: Any ideas for your next project?

Lemieux: Next project is another suit that's easier to assemble, to put on, and that's even more stream lined. I also want to make Ultron. I have some great ideas on lighting his face up.

You can check out the entire process on his website, Ironmanofmaine.weebly.com.

About the Author

Iliza Sokol

Associate Content Producer

Iliza joined the Penton Media group in 2013 after graduating from the Fashion Institute of Technology with a BS in Advertising and Marketing Communications. Prior to joining the staff, she worked at NYLON Magazine and a ghostwriting firm based in New York.