Mentor Graphics' David Wiens Discusses the New PADS Family

Mentor Graphics just announced three new PADS family products for PCB design that, according to the company, start at unprecedented pricing for the independent hardware engineer, delivering affordable dynamic technology solutions to effectively manage today’s complex systems designs.

Wong: There are a lot of PCB design tools out there—how would you categorize the landscape?

Wiens: You can break it down into three areas, largely dependent on the organizational and design complexity being addressed:

1) Enterprise engineering. Most teams within an enterprise are large, distributed (nationally or globally) and specialized. This organizational structure requires tools that facilitate team collaboration, such as IP management (data, process) and process concurrency. Design complexity is also typically high, requiring deep technology for the team specialists to design, validate, and manufacture their product. Tool-selection/purchase decisions are typically made by centralized CAD management and corporate purchasing teams. Tools in this space include Mentor Graphics’ Xpedition Enterprise, Cadence’s Allegro, and Zuken’s CR-5000/8000.

This file type includes high resolution graphics and schematics when applicable.

2) Independent engineering. An independent engineer can reside in a small organization (single-person shop or small workgroup/team creating production designs), or someone in an enterprise who is operating independently of the larger organization (e.g., prototype/concept validation, reference designs, device test, manufacturability assessments). These engineers do the majority of design work themselves, so they must leverage a variety of tools—you could categorize them as design specialists, but tool generalists. They don’t have the same organizational requirements as enterprise teams. Their IP management needs are simpler, and their tool purchase decisions are made at the individual or department level. Product complexity can be as high as those at the enterprise level. Tools in this space include Mentor Graphics’ PADS, Altium Designer, Cadence’s OrCAD, and Zuken’s CADstar.

3) Self-driven engineering: This category has also been referred to as hobbyists and makers. They’re often involved in low-complexity prototypes and one-off designs. These engineers typically operate on their own (not within any corporate structure). Tools in this space include CadSoft Eagle, Pulsonix, and National Instrument’s Electronic Workbench, which tend to be highly commoditized and disposable.

Wong: What are the special requirements of this independent engineer who requires specialized software solutions?

Wiens: The design complexities can be the same for engineers whether they’re working independently or within an enterprise. But where enterprises deploy large teams of specialists on a project, independent engineers have to take on the majority of tasks themselves. So, they become tool generalists, capable of leveraging tools across the flow to design and make tradeoff decisions. This requires a tool flow that is easy to learn and use, and tightly integrated, while also addressing the entire range of complexity within the design and analysis tool suite. Current lower-priced product offerings for independent engineers run out of steam on high-complexity designs, requiring the engineer to improvise time-wasting workarounds just to get the project complete (if at all).

Wong: What’s new with PADS?

Wiens: PADS has built a strong legacy providing solutions to this market—production-proven on millions of designs by hundreds of thousands of engineers—with a reputation for ease of use and affordability. What we’re announcing today is a new set of configurations that provide engineers with even more affordable access to advanced technology never before seen outside the enterprise-level product offerings. They will enable higher design productivity, enhance product quality, and reduce development costs and cycle times.

Wong: Why are there three versions of the PADS products—what makes each one distinctive?

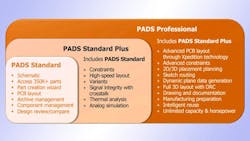

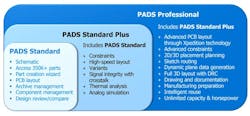

Wiens: All three configurations address the same independent engineer. What’s different is the design complexity the engineer is dealing with. PADS Standard enables core PCB schematic design and layout. PADS Standard Plus builds on PADS Standard with constraint management and simulation tools necessary for today’s high-speed design challenges. PADS Professional builds on PADS Standard Plus with industry-leading technology that has the horsepower and capacity to address the most complex designs with minimal iterations done by outside teams (e.g. mechanical, manufacturing) and shorter design cycles. PADS Professional leverages technology from Mentor Graphics’ Xpedition platform.

Wong: Can you share price points with these configurations?

Wiens: We believe these solutions deliver unprecedented price-performance. PADS Standard is $5K, PADS Standard Plus is $10K, and PADS Professional is $18K. All include first-year support.

Wong: How will PADS be differentiated from its competition?

Wiens: PADS offers unmatched technology in these key areas:

• Correct-by-construction methodology. It’s a constraint-driven environment that delivers products right the first time.

• Integrated, accurate, easy-to-use analysis and verification technology. This will minimize expensive, time-consuming physical prototype cycles with signal/power/thermal/EMI validation technology powered by Mentor’s HyperLynx technology.

• The highest-performing, highest-capacity layout environment. This technology is powered by Mentor’s Xpedition PCB layout product to enable engineers to quickly and efficiently tackle the most complex layouts.

• Part library access. Engineers can access a growing library of 360K+ parts with associated symbols and footprints, reducing manual errors and saving time and cost.

• Price/performance at all levels. Most notably, PADS Standard at $5K, a price point abandoned by competitors like Altium, leaving their customers without a viable solution.

• Scalability. The PADS products enable users to address challenges from simple to complex. As their needs increase, users can scale to advanced configurations, or all the way to the Xpedition Enterprise flow. Today’s independent designs can be tomorrow’s global product initiative.

Wong: You mention affordable access. Why is that important to this audience?

Wiens: Every engineering team is cost-conscious. What’s different about the independent engineer is the ability to leverage financial assets. They work with separate, smaller budgets within an enterprise, and if they’re on their own, they’re working with a personal budget.

Wong: What types of complex designs and applications does the PADS family serve versus a more powerful enterprise software technology like Mentor’s Xpedition platform?

Wiens: The high end of the PADS family, PADS Professional, can address the same design complexities as Mentor’s flagship Xpedition Enterprise flow. The difference is in the organization complexity in a large, global enterprise team. The enterprise team can afford to specialize (signal integrity engineer, layout designer, design engineer, systems designer, manufacturing engineer, etc). But enterprise teams require more infrastructure to leverage IP, such as libraries, designs, reuse blocks, process models, and training. For optimum efficiency, these teams should be enabled to concurrently collaborate during the design process.

Wong: How difficult is the PADS product to use? Since Mentor is offering some sophisticated technologies like analog or thermal simulation and advanced design rule checking (DRC), how long is the learning curve?

Wiens: The focus of this PADS release was to increase ease of use across the flow with tighter integration and a streamlined user interface. Self-paced training is also included to increase time to productivity. The expectation is that engineers can get the product “out of the box” and install/license/train within one to two weeks.

Wong: Can a PCB designer create a custom PADS suite where one could pick and choose specific tools versus using a pre-packaged version of the new PADS product? Or is it more cost-effective to use a current PADS bundle?

Wiens: We have structured the products for the streamlined, transactional sales and acquisition process used by independent engineers, For instance, they don’t employ an isolated CAD management team to benchmark and analyze tools and their impact on the enterprise environment over 18-24 months—they want to make smart decisions quickly and deploy immediately. To support this model, we created three configurations that are self-contained—you can design, layout and manufacture with the tools in the box. The configurations deliver price/performance unparalleled in the industry.

Wong: How can I purchase a PADS product? With the $5K entry point, can I order this online directly and download the software now?

Wiens: PADS is sold through our distribution channel to expedite the sales process and provide local support as you deploy the product. To assist with tool evaluation, we’ve provided an extensive set of product videos, as well as downloadable product evaluations and online virtual labs at http://www.pads.com/.

Wong: How will these new PADS products impact Mentor’s leading enterprise product, Xpedition?

Wiens: There is no impact on the Xpedition Enterprise flow—it is still Mentor’s flagship flow. We are merely continuing the practice of leveraging technology across multiple flows to optimize our R&D investment while addressing the needs of a larger user base. Mentor addresses both technology and organizational needs as the leader in PCB systems design. We have great ability to address every business and technology use-case in the industry while leveraging our extensive portfolio of leading technologies.

Wong: What are users saying about PADS?

Wiens: One customer, Obzerv Technologies, noted that PADS would not only enable them to get their designs done quicker and cheaper, it would afford them time to optimize product performance.

“The biggest pressure that we face is being able to produce a design that is good on the first run,” said Louis Demers, CTO of Obzerv Technologies. “The PADS tool suite is a very cost-effective design solution that tackles our most complex design challenges, as well as providing a growth path for our future needs. The advantage of going with PADS is that we will be able to converge toward a workable design much quicker and with reduced iterations, fewer expenses, and faster delivery to market. We will also have more time to be bold in our design, driving for maximum performance and functionality.”

Astek Corp., another customer, noted that PADS would enable their multi-disciplinary engineers to efficiently optimize products with a high-power, easy-to-use, integrated flow.

This file type includes high resolution graphics and schematics when applicable.

“To achieve maximum engineering efficiency and to optimize our products, our engineers work on board projects from concept through simulation and layout, all the way into manufacturing,” said John Sherman, vice president of Astek. “They need to use a broad set of tools, which means tools must be easy to pick up after a period of non-use. They also push the edge on product complexity, with high-frequency, high-density designs. We believe the PADS technology will enable us to easily tackle our complexity challenges, optimizing the productivity of our multi-disciplinary engineers.”

About the Author

David Wiens

Buisness Development Manager

David Wiens joined Mentor Graphics in 1999 through the acquisition of VeriBest. Over the past 25 years, he has held various engineering, marketing and management positions within the EDA industry. His focus areas have included advanced packaging, high-speed design, routing technology and integrated systems design. He holds a B.S. in computer science from the University of Kansas.

William G. Wong

Senior Content Director - Electronic Design and Microwaves & RF

I am Editor of Electronic Design focusing on embedded, software, and systems. As Senior Content Director, I also manage Microwaves & RF and I work with a great team of editors to provide engineers, programmers, developers and technical managers with interesting and useful articles and videos on a regular basis. Check out our free newsletters to see the latest content.

You can send press releases for new products for possible coverage on the website. I am also interested in receiving contributed articles for publishing on our website. Use our template and send to me along with a signed release form.

Check out my blog, AltEmbedded on Electronic Design, as well as his latest articles on this site that are listed below.

You can visit my social media via these links:

- AltEmbedded on Electronic Design

- Bill Wong on Facebook

- @AltEmbedded on Twitter

- Bill Wong on LinkedIn

I earned a Bachelor of Electrical Engineering at the Georgia Institute of Technology and a Masters in Computer Science from Rutgers University. I still do a bit of programming using everything from C and C++ to Rust and Ada/SPARK. I do a bit of PHP programming for Drupal websites. I have posted a few Drupal modules.

I still get a hand on software and electronic hardware. Some of this can be found on our Kit Close-Up video series. You can also see me on many of our TechXchange Talk videos. I am interested in a range of projects from robotics to artificial intelligence.