Chirp Microsystems Sticks Sonar in Chips That Detect the World Around Them

To detect the size, shape and location of potential prey, bats send out quips of ultrasonic waves and then listen for the echoes to make precise range measurements.

Now a small start-up called Chirp Microsystems is trying to give some of the power of sonar to smartphones and other devices so they can grasp their surroundings in three dimensions.

The company has started sampling its first line of ultrasonic time-of-flight sensors, which consume so little power that they can stay be embedded in consumer electronics like smartphones. The sensors are based on miniature mechanical devices called microelectromechanical systems, or MEMS, which are fabricated the same way as traditional chips.

“Ultrasound is cheap because there is virtually no computation required,” said David Horsley, Chirp’s chief technology officer and co-founder, in an interview. “Because you know the speed of sound, you know the exact range to something.” He added: “We think that ultrasonic sensors allow you to interact with devices in ways that you cannot do today.”

Founded in 2013, Chirp underscores the groundswell of creativity in the sensor industry. The company is part of the booming business of 3-D sensors that can measure the distance to objects so precisely that devices can read hand gestures, follow people around a room, and track eye movements better than cameras using computer vision algorithms.

The market for 3-D sensors is expected to expand four-fold to more than $9 billion by 2022, according to research firm Yole Developpement. They could be installed not only in consumer electronics but also in autonomous cars and warehouse robots that monitor their surroundings to fetch products from storage.

Horsley, on leave from his position as a mechanical engineering and aerospace professor at the University of California, Berkeley, said Chirp’s devices can be packed into laptops that power on when you walk into an office or motion controllers for virtual reality, which would otherwise need complex infrared systems.

Typically, ultrasonic sensors have been too bulky for consumer devices. Their size confined them to applications like back-up sensors in cars and autonomous robot vacuums. They are usually fabricated with ceramic parts shaped like thimbles bonded to a circuit board. It acts like a transducer that sends out ultrasonic pulses.

Chirp replace the ceramic transducer with a MEMS device coated in thin films of piezoelectric material. The company pairs its transducer with a custom system-on-chip, which nulls human speech and other ambient noises that can interfere with the sensor’s measurements. The sensor captures up to 100 samples per second.

“Everything in that giant package is now inside our chip, which has the same range finding performance of a conventional ultrasonic sensor,” said Horsley, one of the directors of U.C. Berkeley’s Sensors and Actuators Center. That was where Horsley started sowing the seeds of Chirp’s technology in 2008. Chirp also licenses its fundamental patents from the lab.

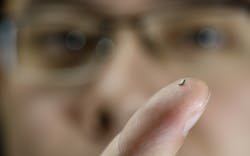

Chirp’s sensors are only millimeters in size and have millimeter-level accuracy. The company’s first product, CH-101, can detect objects from around three feet away, while its CH-201 sensor has a range of more than 16 feet. Both products have the same pin layout and software interface, so that they can be swapped out for each other.

Both sensors operate on a 1.8 volt supply, and have a standard I2C interface. Total current consumption is just 8 µA when measuring 1 sample per second, but the sensors eat through more power as the sampling rate rises. The total power consumption of the sensors can be as low as 15 microwatts, said Horsley.

The startup could walk into a bramble patch of competition. Sony is trying to perfect time-of-flight image sensors that pump out pulses of infrared light to measure distance. In addition, STMicroelectronics sells infrared sensors integrated with vertical cavity surface emitting lasers or VCSELs, which are widely used in smartphones to focus cameras.

The company could also rub against Infineon, which has been trying to shrink automotive radar to fit inside smart speakers that can pinpoint the location of people around a room. Infineon has also consorted with Google to build the experimental Soli radar, which lets people control wearables and laptops with simple hand gestures.

Horsley argues that infrared sensors fumble with direct sunlight and transparent objects, while ultrasonic sensors are unaffected. He added that ultrasonic sensors cannot be fooled as easily as computer vision cameras and they consume far less power than radar chips, which can also suffer from interference from wireless networks.

But the start-up is fighting against the financial firepower of rivals. Earlier this month, Apple awarded Finisar $390 million to boost production of infrared lasers used in the iPhone X. They are a critical component of Apple’s TrueDepth camera, which projects infrared light onto a person’s face to digitally map its minute contours and features. That allows a user to unlock their smartphone or authorize mobile payments by looking at it.

Chirp is also targeting smartphones. Both sensors have 180-degree fields of view, and that means they can be mounted on the top and bottom sides of the smartphones. "Since this is the location of the microphone and speakers, it’s easy for designers to add another acoustic sensor," said Michelle Kiang, Chirp's chief executive, in a statement.

Horsley declined to disclose Chirp’s total funding. But the company has raised several million dollars in government grants to fuel development and purchase the thin-film deposition equipment in U.C. Berkeley's Sensor and Actuator Center, where the first prototypes were fabricated. He added that Chirp plans to double its staff to 30 employees over the next year.

About the Author

James Morra

Senior Editor

James Morra is the senior editor for Electronic Design, covering the semiconductor industry and new technology trends, with a focus on power electronics and power management. He also reports on the business behind electrical engineering, including the electronics supply chain. He joined Electronic Design in 2015 and is based in Chicago, Illinois.