2020 Vision: Industrial Solid-State Storage

As we enter the new decade, a confluence of applications is migrating to the edges of networks that will extend the need for industrial-grade solid-state storage and memory. In addition to traditional industrial usage, seven critical “smart cities” applications will accelerate adoption (Fig. 1):

- 5G mobile and broadband telecommunications

- Renewable energy infrastructure

- Green buildings, parks, and public spaces

- Public transportation and mobility

- Public safety (security and surveillance)

- Health and human services (medical)

- Secure payments and financial transactions

Most, if not all, of these new applications require some type of artificial-intelligence (AI) algorithms running on new processors with increased storage capabilities and performance levels similar in speeds to enterprise-grade solutions. In response to all of this, the standards bodies have been busy finalizing higher-speed data transport layers such as SATA 3.3 (16 Gb/s) and PCIe Gen 4 (2 Gb/s/lane for up to 16 lanes) using NVMe protocol, as well as new embedded storage specifications like USB 4, SD Express, eMMC5.1, and UFS3.0

Besides impacting interface speeds, the type of NAND used also affects performance as writing or reading to/from more bits takes more time. Single-level cell/1-bit (SLC) NAND is fastest, multi-level cell/2-bit (MLC) is the next fastest, triple-level cell/3-bit (TLC) is slower, and quad-level cell/4-bit (QLC) is slowest.

And while these standards get ratified, 2020 will see security being front and center for all types of industrial Internet of Things (IIoT) deployments. Data can be made highly secure with Advanced Encryption Standard (AES) algorithms, which are transparent to the user as encryption is handled by a dedicated crypto processor on the solid-state drive (SSD). Such a processor, a standard building block for NAND flash controllers, is usually complemented by a secure-erase mechanism that can completely wipe clean all data found on an SSD to provide the maximum level of security for sensitive data that must be erased.

Finally, ruggedization, extended temperature operation, and high endurance will continue to be key requirements in 2020 as these systems deploy in various industrial environments that expose them to harsh weather, heavy workloads, and other challenging conditions.

The Storage Trifecta

Based on all these dynamics, Virtium forecasts the industrial-grade storage market will split into three main categories:

- High-performance, high-density drives (up to 64 TB) in M.2 form factors using two, four, or eight lanes of PCIe along with the NVMe protocol. Performance—sustained throughput of 3 GB/s—comes at the expense of slightly higher power consumption. Due to the higher density requirements, most of these drives will use 3D TLC NAND and some will use QLC.

- Medium-performance but lower-power drives using the AHCI protocol in various SATA form factors such as mSATA, SlimSATA, 2.5-in., and M.2. Many applications will do just fine with a SATA SSD sustained throughput of 550 MB/s. Based on endurance requirements, the NAND options here can be 3D TLC, MLC, and even SLC in some cases. There’s always an option to do pseudo SLC (pSLC) by over-provisioning 3D TLC or MLC configurations. Each NAND technology also has its own availability curve, ranging from a low of two to three years to a high of five to seven years, for deployments where servicing or requalification is particularly challenging.

- Embedded SSDs with the PCIe interface also in multiple form factors such as microSD, eUSB, CFast, eMMC, BGA, and eUFS. Multiple NAND options are available for such drives, too.

The total available market (TAM) for these applications is expected to reach over $5B in 2023, based on our market analysis and supported by various research reports.

An emerging category of SSDs involves highly ruggedized drives that go into systems designed for the harshest of environments, where shock, vibration, extreme temperatures and other factors affect reliability. Compelling needs like that directed Virtium to develop the StorFly-XR line of SSDs and DIMM memory modules, whose specialized connectors, conformal coating, I-Temp support (−40 to 85ºC) and power-fail protection combine to combat the impact of those harsh environments.

As designers ponder what type of SSDs to use, they need to keep in mind endurance requirements for their specific application. Microsoft published an insightful article on understanding SSD endurance. To help them account for all parameters, Virtium recommends designers review a selector guide and total cost of ownership (TCO) calculation sheet (contact the company to request one). In addition, we highly recommend using software tools such as StorKit to monitor the health of the drive and flag down any potential outages ahead of their occurrence.

There’s a wide range of densities and form factors from DIMM module suppliers (Fig. 2). They include densities ranging from 16 to 64 GB and various form factors such as SODIMM, UDIMM, ULP UDIMM, RDIMM, ULP MINI-UDIMM, MINI-RDIMM, and more.

This year promises to be another exciting year for industrial storage and memory as 3D-TLC NAND matures, QLC ramps into production, and a slew of new products come to market to support rugged new applications.

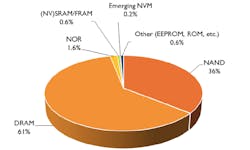

As NAND continues to rule the non-volatile memory segment, DRAM continues its dominance of the volatile memory space. 2020 will bring the ratification of the DDR5 module JEDEC specification, but DDR4 form factors will remain the mainstream module of choice in the foreseeable future.

Jacques Issa is Senior Vice President at Virtium Solid State Storage and Memory.