Near-Infrared Sensor Technology Shines in Low/No-Light Conditions

In the second generation of its near-infrared (NIR) technology for image sensors that operate in low to no ambient light conditions, OmniVision Technologies offers silicon semiconductor architectures and processes that have hit new heights in quantum efficiency. The Nyxel 2 technology provides a 25% improvement over the preceding generation in the invisible 940-nm NIR light spectrum and a 17% bump at the barely visible 850-nm NIR wavelength.

These sensitivity improvements enable image sensors to see even better and farther under the same amount of light, further extending the image detection range. Nyxel 2-based camera systems also require fewer LED lights, thus reducing overall power consumption and extending battery life. These added benefits make Nyxel 2 a good candidate technology for surveillance systems, automotive in-cabin driving monitoring systems, and the burgeoning under-display sensors in mobile devices.

Machine- and night-vision camera applications rely on NIR technology because NIR light illuminates objects with wavelengths outside the visible spectrum, avoiding any interference with the surrounding environment. Additionally, because the night sky contains more NIR photons than visible photons, greater NIR sensitivity allows for higher-resolution image capture with fewer power-hungry LEDs, which is highly desirable for battery-powered and night vision security camera applications. Earlier NIR detection approaches fell short of the performance requirements for next-generation mobile and AR/VR products with embedded machine vision applications, as well as automotive and security cameras that require higher NIR sensitivity.

Competing CMOS approaches for NIR image sensing continue to rely solely on thick silicon to improve NIR sensitivity. However, this results in crosstalk and reduces the modulation transfer function (MTF). Attempts to overcome this by introducing deep-trench isolation (DTI) often lead to defects that corrupt the dark area of the image. With Nyxel 2, OmniVision has refined its approach to NIR imaging that combines thick-silicon pixel architectures with careful management of wafer surface texture to improve quantum efficiency (QE), along with extended DTI to retain the MTF levels of the first generation without affecting the sensor’s dark current.

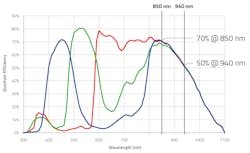

With these refinements, OmniVision’s Nyxel 2 achieve 50% QE at 940 nm—a 25% improvement over the first generation, as measured using data from a 2.9-micron pixel. At the 850-nm NIR wavelength, Nyxel 2 can provide 70% QE, which is not only a 17% improvement over the first generation, but it is now on par with the QE levels of top RGB sensors that operate with visible light. The results of these Nyxel 2 technology improvements are even higher image quality, greater image detection range, and further reduction in light source requirements for even lower power consumption and extended battery life.

Nyxel 2’s performance improvements provide a range of new possibilities to designers. For surveillance systems, the number of IR LEDs around security camera lenses can be further reduced to save on both cost and power consumption, or the same number can be used to increase the brightness of captures taken in total darkness. For automotive driver-monitoring systems, accuracy can be increased while placing fewer LEDs in harder-to-see places within the cabin. For smartphones, the LEDs can be reduced to aid in the never-ending quest for extended battery life, while squeezing more components into compact form factors that both enable design innovation and reduce BOM costs.

OmniVision’s first image sensors with Nyxel 2 technology are expected to be available during the second half of 2020.

OmniVision Technologies, www.ovt.com