Take a System-Engineering Approach to Complex Designs

What you’ll learn:

- A system-engineering approach is essential for an efficient design in a complex system.

- Comprehension of conflicting requirements of participating subsystems and integrated designs are key elements for the success of large systems.

- Systematic follow-up of a lifecycle process in a system like a launch vehicle helps in achieving high-quality outcomes, on-time schedules, and no cost overruns.

Complex systems invariably comprise several subsystems and components, and often these elements belong to different engineering disciplines. The design of such complex systems can’t be carried out without having the clear understanding of all participating subsystems and the role played by each of them. Efficient design of these systems can be done by utilizing the systems engineering approach right from the concept stage.

System engineering is a well-structured, end-to-end process. It focuses on capturing the customer requirements very early during the development cycle, documenting the same, carrying out the design in detail considering all aspects, proceeding with the development, and then validating the design by closely monitoring the entire development process.

The system engineering process must follow strict, well-defined steps, including requirements analysis, strategies to meet the requirements, formulation of strategies that are iterative, the design synthesis, and finally verification and validation of the design. A holistic approach must be implemented to mitigate risks all through the development cycle.

System engineering should consistently monitor the technical performance, quality, schedule, cost, and interfacing requirements. Verification and validation are important processes to ensure that the design outputs satisfy the projected requirements. Therefore, application of system engineering in complex systems becomes essential to realize a system with high quality meet the projected schedules and avoid cost escalation.

Pinpointing Conflicting Situations

The design process in complex systems can’t progress smoothly without having a clear knowledge of conflicting requirements of all participating subsystems. This can be achieved through the design iterations to sort out conflicting situations. In addition, good clarity on the interfaces among disciplines is quite essential. Visualizing the interaction between disciplines is another important ingredient.

The design of a complex system must address all of those factors and try to achieve a good balance between the conflicting requirements and possible interactions. The design efforts also need an integrated approach with the active involvement of different specialists from each of these disciplines and address issues related to conflicting requirements, interfaces, and interdependencies.

The design needs in such complex systems are essentially:

- Understanding the overall functional requirements of the system.

- Generating the unambiguous system definition from the overall system requirements.

- Identifying different subsystems and components that form the system.

- Choosing a suitable subsystem after detailed tradeoff analysis for each subsystem.

- Spelling out broader specifications for each of the subsystems so that their design tasks can be carried out independently.

The subsystem designed has to meet not only the functional requirements, but also satisfy the defined constraints imposed by other participating subsystems and elements.

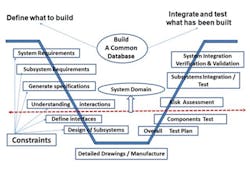

The V-diagram (Fig.1) illustrates a typical system-engineering process, to be followed meticulously in building complex systems. While the left leg elaborates the design process, the right leg deals with the system integration along with the verification and validation process of the design. The bottom horizontal zone represents the entire manufacturing and realization of the system. The dotted line in between separates the system and component domains. Building a common database for the entire system and updating the same periodically whenever change occurs helps avoid design errors. All subsystem developers must utilize the common database to eliminate mistakes.

An Example of System Engineering: A Closer Look at a Launch Vehicle

Let’s consider an example of designing a complex system like a launch vehicle, whose main task is to transport a spacecraft to a well-defined orbit. This system will have several major participating subsystems, such as propulsion, vehicle structures, aerodynamics, flight mechanics, navigation, guidance and control (NGC) systems, avionics, stage auxiliary systems, thermal systems, and the like.

The optimum design of a launch vehicle involves various steps, including mission definition, requirements analyses, subsystems definition, concept analyses and definition, and design. Avoiding adverse interactions among subsystems and defining proper interfaces between disciplines are important in order to arrive at robust design. The final functional performance of the vehicle depends on the operating environment faced by the subsystem(s).

In launch systems, many of the subsystems are subjected to hostile environments like temperature, vibration, and shock during flight. In addition, we can expect dispersions on the specified environmental parameters. Prediction of uncertainty bounds on the environmental parameters must be made carefully, and suitable margins have to be built into the design to take care of such uncertainties.

An efficient design demands a structured multidisciplinary design process to avoid the conflicts between subsystems and have an effective integration of various subsystems. In space missions, quality and cost are two important factors that need serious consideration. Space systems aren’t tolerant—even for a minor quality lapse—and, hence, the quality and reliability should be consistently watched during the design and development phases.

The interfaces between subsystems should be finalized whereby the system complexity and interaction between subsystems are minimized. During realization of the system, the ease of manufacturing and testability are to be appropriately factored.

One of the essential steps in system engineering is assessing the risk involved and its evaluation through a systematic failure analysis during the design phase itself. Strict configuration control of all elements and subsystems is a major activity that enables full traceability during the entire lifecycle of the system realization from concept to operationalization.

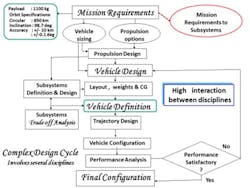

The mission requirements in terms of the spacecraft mass and its orbital parameters are the basic inputs for the design.1 Selection of the propulsive stages and structures that accommodate various subsystems decide the overall vehicle size. When selecting these elements, it must be based on the state-of-the art technology available. The realization time, cost, and reliability requirement dictate the selection process. Once the vehicle size in terms of number and type of stages are decided, the overall layout, configuration, propellant, and inert masses along with inertial properties are worked out.

The aerodynamic characterization of the vehicle is the next step. Suitable trajectory design is another major milestone. The system demands generation of a few trajectories. A suitable trajectory is selected based on simulation results that meet the defined requirements of the dynamic pressure, the load on structure, the thermal load, etc., during flight even under the varying environmental conditions.

Once the trajectory design is completed, the design of other subsystems like thermal; navigation, guidance and control (NGC); stage mechanisms; etc., are carried out, utilizing the trajectory finalized. The systematic approach for the design of a typical launch vehicle system is shown in Figure 2.

Specific System-Engineering Aspects

Certain system-engineering aspects to be considered while finalizing the systems requirements, system configuration, identification of subsystems, and their specifications are the detailed tradeoff studies, analysis to eliminate the interactions between the subsystems, risk analysis, and its management.

Tasks of the System Engineer

In complex systems, proper selection of suitable subsystems meeting the overall requirement is vital. This can be achieved only by considering a number of alternate concepts during the design phase and critically evaluating each of the options, considering the performance requirements, realization feasibility, the elements involved, the timelines for realization, and overall cost. One needs to address the cost-effective design, which has to factor in the cost involved in manufacturing, testing, and validation. Based on the detailed analysis, the most suitable concept must be chosen, and it should meet the specified goals, stipulated conditions, and constraints.

Let’s examine the integrated design approach in a multidisciplinary launch vehicle consisting of subsystems like propulsion, structures, aerodynamics, navigation, NGC, thermal system, and vehicle auxiliary system. We need to adhere to all system engineering principles. The subsystems of a launch vehicle are closely linked with each other and have their own interdependencies and interactions.

The selection of propulsion systems depends on number of stages chosen, which again depends on the state-of-the-art technologies available. The propulsion design is greatly influenced by the type of structures chosen, various loads experienced during flight, the control systems employed, and thermal environment experienced during the flight.

Propulsion system parameters that need serious attention are thrust time profile, propellant consumption history, transients due to ignition and shut-off, and liquid slosh and its impact. The control in launch vehicles is mostly derived utilizing the deflection of the propulsion engine/nozzle and, hence, the maximum deflection angle needed. In addition, its influence on the overall thrust delivered by the stage must be assessed. The number of propulsive stages and inter-stage structures contribute to the vehicle structure. The requirement is to have lightweight structures that will survive the maximum vehicle loads experienced during flight.

The control structure interaction is another dimension in the design. This problem can be handled by keeping enough separation between the structural and control frequencies of the vehicle. In liquid stages, the slosh effect, which is essentially the oscillation of the fluid in the tank, has to be managed by introducing required damping through baffles in the tanks.

While estimating the vehicle loads, aerodynamics plays a dominant role. Choosing the right vehicle configuration is essential, as the aero load is decided based on the configuration, vehicle protrusions, and elastic properties of the vehicle. Aerodynamic heating during the atmospheric phase is another vital factor. The aerodynamic load distribution along the vehicle must be assessed by the measurement of the pressure distribution using the experimental tests in a wind tunnel. The estimation of bounds for dispersions for various aerodynamic parameters is a very difficult task and requires lots of analysis and experimentation.

The vehicle trajectory design and sequencing the flight events have close links with all subsystems of the vehicle. The requirements of trajectory design include:

- Limiting the dynamic pressure during the atmospheric flight, within the specified value.

- Minimizing the load experienced by the vehicle due to aerodynamics in the atmospheric phase.

- Minimizing the thermal heating of the vehicle subsystems.

All of these requirements demand a number of design iterations, and the trajectory has to be verified for all performance parametric variations specified for the subsystems.

The sequencing design during the transition region between the two stages must utilize suitable robust techniques to ensure smooth separation without collision. Invariably during the transition, several subsystems participate and, hence, their designs have to account for adequate robustness to achieve the mission success.

Navigation guidance and control (NGC) is another major subsystem. The spacecraft injection’s accuracy depends largely on the accuracy of sensors (gyros and accelerometers) in the navigation system. Any deformations at the location of the sensor mounting also contribute to the errors.

The major function of the guidance and control system is to inject the spacecraft into the specified orbit within the prescribed errors. Its performance is influenced by other subsystems like propulsion, aerodynamics, separation system, actuators, sensors, and the like, as their dispersions may cause errors. The control system must ensure the stability of the system all through the flight. The control system gets its input from the guidance, which computes the guidance commands on board to direct the vehicle to follow the predefined trajectory path.

The system engineer should have a good working knowledge of all subsystems and needs to keep continuous watch on their performance. This is essential to keep track of the entire configuration and its changes, because a change in any of the subsystems may have serious implications on the performance of other subsystems. Therefore, these factors should be carefully analyzed before the change is accepted.

Risk Assessment in System Engineering

In complex systems, risk assessment is one of the most important steps. It must address specifically the kind of failures, their possibilities, and their consequences. A number of well-established procedures and analysis tools are available to help with this. These tools assess the failure possibilities and the risks involved in such failures. The analysis must classify the risks as acceptable or otherwise, depending on the consequences. Such analysis results demand incorporation of the design improvements wherever necessary.

System Testing and Validation

During the realization phase of the components, subsystems, and systems, devising judicious test methodologies is crucial to their performance evaluation. As explained in the right leg of the V-diagram (Fig. 1, again), a suitable matrix for tests must be generated to evaluate the performance of all elements in a progressive manner. Not only do they need to address performance evaluation, but also environmental tests depending on the kind of environment experienced by each of the subsystems. Validation of system performance under the operating environment of each subsystem (thermal, vibration, electromagnetic interference, shock, acoustics, etc.,) is essential.

In a typical launch vehicle system, certain performance tests at an integrated level can’t be carried out. When facing such situations, one has to resort to proper mathematical modeling and detailed simulation. This demands development of suitable simulation test beds. It’s also possible to integrate the hardware with simulation test beds—this must be planned during the development phase.

In all subsystems, suitable tests should be defined both at component and subsystem levels. These tests should enable the evaluation of interfaces, system performance, and design margins. All aspects of integrated system performance can’t be evaluated in a single test bed. Rather, different simulation test beds with specified objectives for evaluating different aspects of the integrated system performance are needed.

Furthermore, we need to carry out simulations by integrating the flight hardware in a progressive manner to evaluate the performance of hardware in the software environment. The integrated simulation tests help establish the system robustness under all combinations of flight environment, parametric dispersions of subsystems, and even various failure modes. To evaluate the comprehensive performance of the system under all operating conditions and possible performance deviations of the participating subsystems, the test cases should be chosen judiciously to ensure that all possible conditions are considered.

Conclusion

Complex systems are essentially multidisciplinary, and today almost all systems starting from simple toys to space travel are highly multidisciplinary with serious interrelationships. Therefore, the realization of such systems meeting the quality requirements, adhering to the projected schedule, and staying within the envisioned costs can’t be done without the application of system engineering. It also helps to minimize risk, helping achieve a greater success rate.

The entire process was explained by considering a multidisciplinary and multidimensional system like a launch vehicle that has several subsystems. The interactions and interdependencies between the participating subsystems are very intense, and interface definition is also quite cumbersome. A typical launch vehicle utilizing system engineering is an excellent example of the integrated design and development process.

Dr. B.N. Suresh is Chancellor of the Indian Institute of Space Science and Technology (IIST).

References

1. Suresh, B.N. and Sivan, K., “Integrated Design for Space Transportation System,” Springer India, 2015.

2. Gupta, S.C., Suresh, B.N., and Sivan, K., “Evolution of Indian Launch Vehicle Technologies,” special edition of Current Science, Vol. 93, No. 12, Dec. 2007.

3. Suresh, B.N., “Space transportation systems in India, present scenario and future perspectives,” Journal of Aerospace Sciences and Technologies, Vol. 61, No. 1, February 2009.

4. Gupta, S.C. and Suresh, B.N., “Development of navigation guidance and control technology for Indian Launch Vehicles,” Sadhana, Vol. 12, Part 3, March 1988.

About the Author

Dr. B.N. Suresh

Chancellor, Indian Institute of Space Science and Technology (IIST)

Dr. B.N. Suresh’s space systems engineering expertise and leadership has been instrumental in the Indian Space Research Organization (ISRO) becoming one of the world’s top space agencies known for launching successful missions at lost cost.

Suresh led the development of their navigation, guidance, and control (NGC) systems for all launch vehicles of India, including the ISRO’s workhorse Polar Satellite Launch vehicle, PSLV. He led the design and development of the electrohydraulic and electromechanical control systems, which are flying in all launch vehicles. His work also eliminated the high cost of importing components for actuation systems.

His contributions have enabled ISRO to achieve success in several complex missions, including the space recovery experiment (SRE) in 2007, which was successful in recovering the module in precise location in its first attempt. Dr. Suresh is presently Chancellor, Indian Institute of Space Science and Technology (IIST), Thiruvananthapuram and Honorary Distinguished Professor at ISRO HQ, Bangalore. He’s the recipient of over a dozen research and technical achievement awards, including his most recent in 2020 from IEEE, where he was co-recipient of the IEEE Simon Ramo Medal for his outstanding leadership in developing a national space program and pioneering space technology.