Why a Decentralized Architecture in Robotics is the Logical Choice

What you’ll learn:

- What features a cobot must include to achieve collaborative operation.

- How centralized and decentralized systems differ.

- Functional safety needs and considerations.

With the need for more collaboration between robots and humans, the definition of vertically articulated robots has shifted from working in a collaborative workspace to collaborative operation. In a collaborative workspace, there’s no direct cooperation between robot and human, whereas collaborative operation entails direct cooperation between the two.

In collaborative operation, a collaborative robot (cobot) supports human workers by performing repetitive tasks and ensuring high product quality in often space-constrained environments. Leaving the more repetitive work to the robot allows workers to focus on other, more important tasks on the production line, such as making fine adjustments and performing optical inspections of subsystems.

It’s important that a cobot is cost-optimized, and that it has a size and safety assessment capability when set up on a factory floor, with features to help ensure employee safety.

When upgrading a compact factory floor with robots, it’s sometimes not possible to create a safety fence or area around each robot and still maintain production efficiency. Collaborative robots with built-in safety no longer require this additional safety area, which makes it easier to integrate the cobot into the existing workflow and increase quality and output (Fig. 1).

To achieve collaborative operation, a cobot must include these features:

- Safety-rated stop monitoring

- Speed and separation monitoring

- Power and force limiting

It’s possible to implement safety-related features by complying with International Organization for Standardization (ISO) 10218-1:2011, with technical amendment ISO/TS 15066 and American National Standards Institute/Robotic Industries Association R15.06 2012 standards.

Cobots are typically built to move weights (payload) of between 15 kg to 30 kg. This weight is typically the force that a cobot needs to conduct its working task. Such a change of payload also leads to rethinking the full architecture of how the robot is working, which also affects its size and weight. Change of architecture typically leads to changing the hardware from a centralized architecture to a decentralized architecture.

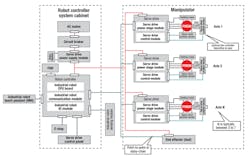

Centralized systems locate the main functions (logic control, motion control and coordination, motor control, sense processing) together, typically in large cabinets some distance from the manipulator. An extensive network of wires handles power, feedback and control of motors and sensors.

In a decentralized system, some of these functions move to the robot cabinet, into the arms and joints, and even embedded with the motors themselves. Figure 2 shows a simplified example of a decentralized system.

Getting Decentralized

When decentralizing electronic content, remember that the environments where the electronics are used differ from the environments of a centralized system. This disparity necessitates respecifying the electronics and perhaps even redeveloping part of the system.

Defining some subsystems early in the redevelopment process ensures a smooth development cycle, these subsystems could include:

- Low-latency real-time motor control and sensor feedback to achieve smooth, precise, and efficient motion of the manipulator.

- A communication bridge between internal and external interfaces of the cobot.

- Any required functional safety and security needs to help ensure user safety and product certification.

The Texas Instruments (TI) C2000 microcontroller can achieve low-latency real-time control and sensor feedback while still having smooth, precise, and efficient motion by using hardware accelerators and highly flexible and integrated peripherals. The processor is the heart of the cobot, but without analog circuits around the processor, it’s not possible to make the cobot system move with the necessary performance and functions.

Optimized mixed-signal semiconductors have the flexibility to interface to various rotary sensors, different methods of sensing analog currents and voltages (or interfacing with sensors), processing feedback and calculating a control response in the shortest time possible, and generating a series of precise outputs to properly control motor-inverter power electronics.

Part of the design effort involves ensuring that the analog components can provide the necessary precision and low-latency and efficiency needs for the cobot. Considering different interface and sensing technologies will preserve system performance, even in a noisy factory-floor environment. Those architecture considerations will also affect the power architecture of the cobot, which must provide noise-free point-of-load rails to supply the high-precision analog and processor components.

A communications bridge in a cobot needs to address low-latency, low-jitter sharing of information from the sensors, distributed controllers, system controller, end effector (tool), as well as any higher-level coordinated automation. For example, TI’s Sitara processor can achieve these requirements using multiple coprocessors that enables deterministic, low-latency, low-jitter communication interfaces in a flexible way. The interfaces can support both proprietary and standard real-time protocols using the same pins on the processor. There are many interface options, with tradeoffs in speed, reliable communication distance, robustness, system safety capability, and overall cost.

Standard Fare

Of course, it’s pointless to discuss system functions without also considering both worldwide and local functional safety and security standards. Several organizations offer consulting services to help you understand the hardware implications of designing a safe system according to safety standards, including Technischer Überwachungsverein (TÜV) Rheinland, TÜV SÜD, and TÜV NORD.

To support you in this effort to speed up certification processes, semiconductor companies provide documentation and resources such as the functional safety failure-in-time rate; failure modes, effects, and diagnostic analysis; safety certificates; and software diagnostics libraries. These resources can accelerate the development of a safe cobot system architecture.

Conclusion

A cobot is a very complex system with many design challenges within mechatronics, safety, and functionality, as well as electrical considerations. You’ll need to solve these challenges and make some feature decisions before a working system is possible.

With all of the different technical aspects of a robotic system, embedded technologies offer many different products and designs that can help solve robot-related issues and enable the development of intelligent, autonomous, and collaborative cobots.

About the Author

Kristen Mogensen

System Design Engineer, Texas Instruments

Kristen Mogensen is a system engineer for industrial factory automation and control at Texas Instruments with a focus on robotics. He has broad experience in analog and both processor and MCU technologies with a strong focus on motor control and communication systems used in robotics systems.

Mogensen received his Master of Science in Electrical Engineering at the Technical University of Denmark (DTU).