Skip the Implantables—This Tiny Sensor/Telemetry “Mote” is Syringe-Injectable

What you’ll learn:

- How an ultra-tiny, injectable energy-harvesting, temperature-sensing, and data-link system was developed.

- The use of ultrasound energy to provide both a wireless power source and data link.

- How a piezoelectric sensor and oscillator circuit can be used to sense and report on temperature.

- The impressive accuracy results and depth range achieved with this microchip system.

There’s been considerable interest, research, and yes, even grant money devoted to developing self-powered sensors that can be used within the body to measure and report on parameters such as temperature. Adding to this effort, a team at Columbia University has developed a standalone probe for real-time body-temperature sensing that uses a conventional ultrasound imager to provide wireless power and data communication.

The sub-0.1-mm3, sub-1-nW device, which they refer to as a “mote,” achieves its impressive miniaturization through monolithic integration of a custom low-power temperature sensor chip with a piezoelectric transducer fabricated on the top. The tiny volume of these motes—they are visible only under a microscope—allows them to be implanted or even injected into the body with a hypodermic needle.

The single-chip mote has no internal wiring and requires no additional packaging. It was fabricated at the Taiwan Semiconductor Manufacturing Company (TSMC) with additional process modifications performed in the Columbia Nano Initiative clean room and the City University of New York Advanced Science Research Center (ASRC) Nanofabrication Facility.

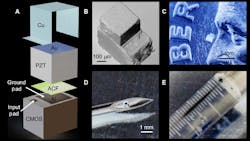

The mote consists of a temperature-sensor IC manufactured using 0.18-µm bulk CMOS technology with a monolithically integrated, microscale piezoelectric transducer made of lead zirconate titanate (PZT). As it needs no bonding wires, solder joints, and circuit boards, the 0.3-mg mote measures only 380 × 300 × 570 µm (0.065 mm3) with direct mechanical and electrical connections between the PZT transducer (300 × 300 × 267 µm) and the IC (Fig. 1).

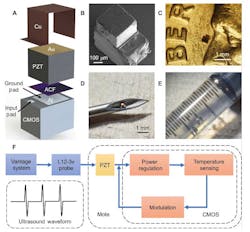

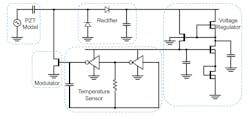

A customized and pulsed ultrasound signal is generated using the imaging probe of a commercial ultrasound system. In addition to providing power, the imager communicates to the mote with acoustic backscattering through modulation of the on-chip PZT transducer electrical load. The IC operates most of its transistors in the subthreshold regime with a gate-source voltage of around 0 V, thus reducing power consumption to ∼0.8 nW at physiological temperature (37°C) (Fig. 2). The power-regulating block at the front end, which converts and regulates the harvested energy from the PZT transducer, has a conversion efficiency of better than 71%.

The oscillator frequency is designed to vary with temperature by exploiting the temperature dependence of the leakage current flowing through a subthreshold-biased transistor. The oscillator controls a modulator that places either a high or a low impedance across the transducer periodically, resulting in modulation of the power of the backscattered ultrasound. This modulation causes the amplitude of the reflected ultrasound echo to vary with the same frequency as the oscillator. At the ultrasound imager, measurement of this oscillation frequency indicates sensed temperature.

The ultrasound pulses are separated by 1 ms and configured with a graphical user interface (GUI) that has a pulse repetition rate of 1 kHz (Fig. 3). Each pulse consists of four cycles at the 8.3-MHz ultrasound carrier frequency. At this frequency, the lateral resolution of the imager is ∼280 µm and the focal spot size is ∼350 µm, both of which are smaller than the physical device size of the motes. (The team notes that in their in vitro test-bench trials, they have been able to locate and interface with two motes spaced less than 10 µm apart.)

Extensive in vitro and actual-tissue (in vivo) tests were done to determine both reading accuracy and depth at which the mote could be read (Fig. 4). Accuracy was better than ±0.05°C over the admittedly limited span needed for body-temperature measurement, while the ultra-low power minimized self-heating that would corrupt the reading validity. Viable sensing depths were on the order of 5 mm to several centimeters.

This work was supported in part by a grant from the W. M. Keck Foundation and by the Defense Advanced Research Projects Agency. Full details of the project, including technical background, context, design, fabrication, test fixturing, and test (including in vivo with close-up photos), along with performance data and subsequent analysis are in their readable paper “Application of a sub–0.1-mm3 implantable mote for in vivo real-time wireless temperature sensing” published in Science Advances (AAAS), and accompanied by their posted “Supplementary Materials.”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.