Go “Beyond the Shelf” to Find the Right Connector for Your Custom Design

There are countless combinations when it comes to choosing a perfect connector for one’s engineering project. A connector is a base component of any electronic product, since it connects the entire electronic system together. And it plays an important role in achieving success for an embedded-system design. Below are some custom connector solutions that might overcome those design obstacles.

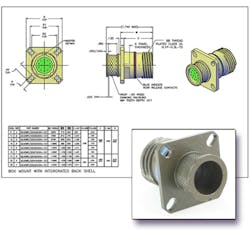

Connectors with Integrated Backshells

For connector applications where weight reduction and increased shell-to-shell conductivity are paramount, connectors with integrated cable-management features are often the best fit. Cable clamps, banding porches, shrink boot adaptors, and other widely used backshell configurations are integrated directly into the connector in lieu of accessory threads and user-installed accessories.

Common styles are machined from a single piece of aluminum or stainless steel, and plated in accordance with mil-spec requirements. The result is a connector with exceptional electrical conductivity, a low-profile rear end, and fewer components—and often at a lower total system cost compared to a traditional connector and backshell. Shown above is a box mount with integrated backshell.

Cylindrical Connectors with PC Tail Contacts

For applications where size, weight, and electrical performance are of critical, connectors designed to mount directly to printed-circuit boards (PCBs) offer clear advantages over traditional “crimp and poke” contact terminations.

PC tail connectors are most often based around common mil-spec connectors—including D38999, M28840, M83723, and M24308—and are intermateable with off-the-shelf plug connectors. However, they differ in their ability to mount directly onto a rigid, semi-rigid, or flexible PCB by means of special PC tail contacts. Contacts come in a variety of diameters, lengths, materials, and plating configurations to ensure a perfect fit with board-level hardware.

Connector bodies are available in configurations optimized for use on electronics boxes. Styles include low-profile box mount and jam nut receptacles, integrated PCB standoff feet, and traditional accessory threads—all of which feature aluminum, stainless-steel, and/or composite bodies.

Double-Flange Connectors

Double-flange D38999 connectors enable users to securely install wall-mount or jam nut connectors directly onto PCBs without the use of flimsy standoffs or aftermarket adapters. For example, Air Electro has developed double-flange connectors that meet all applicable requirements of D38999 to ensure intermateability with qualified mil-spec plugs. They have a rugged one-piece machined shell that incorporates PCB standoff feet and mounting hardware.

Connectors can vary between standard and customized configurations, in a full range of mil-spec approved plating finishes. In addition, they can be supplied with a wide selection of PC tail contacts already installed.

Filtered Connectors

Filtered mil-spec circular and rectangular connectors—including D38999, M24308 D-subminiature, M83723, and others—are designed to protect sensitive electrical equipment from unwanted electromagnetic interference (EMI), radio-frequency interference (RFI), and transient voltage spikes.

Filtering can be accomplished by integrating capacitors, diodes, ceramic planar arrays—or any combination thereof—into a connector’s contacts to achieve the desired attenuation levels. Planar arrays are most commonly used, and provide a lightweight, low-profile, and effective means of removing unwanted high-frequency noise from an electrical system. Diodes allow a connector to shunt spikes in voltage to the ground in the event of a surge, such as lightning strike.

Common filtering types include C, L-C, C-L, and Pi, selected based on the capacitance value desired. All types can be packaged inside inline, piggy-back, dual-flange, or custom-designed shell configurations to meet the space requirements of every application.

Sealed Connectors

Sealed connectors are ideal for mission-critical applications that call for lightweight, highly environmental-resistant I/O connections. Epoxy-sealed connectors offer outstanding moisture and gas ingress protection, and are an excellent alternative to glass-to-metal sealed hermetics, whose weight, expense, and long lead times often make them unsuitable for certain applications.

A broad range of standard connector families are used in these types of applications, including D38999, M24308, M26500, M83723, and others. These can be tailored to each application’s temperature, sealing, and electrical requirements. Available shell options typically include integrated PCB standoffs, low-profile, standard accessory mounts, and integrated backshells. Connectors can be supplied pre-wired (pigtails) or with PC tails, and come with standard M39029-type signal contacts as well as high-frequency, matched-impedance coax, twinax, and quadrax contacts.

For more details about these connectors, check out Air Electro’s site.