Three-Axis MEMS Accelerometers Transform IoT Machine Monitoring (.PDF Download)

Quantifying the vibration of industrial machinery and using that information for condition monitoring (CM) has long been an ambitious goal, but also one with significant technical and implementation challenges. It’s usually done using accelerometers that sense motion and provide a corresponding signal for further analysis.

While that approach seems straightforward, the reality has been more much difficult until recently. Now, however, the availability of high-performance, multiaxis accelerometers based on MEMS technology has radically transformed and improved the situation in many ways.

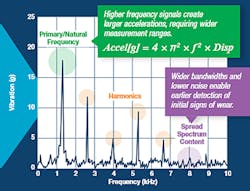

Why vibration? In a perfect world, there would be no vibrations from bearings, shafts, and other components of rotating machinery. These vibrations are due to unavoidable imperfections, balance issues, and slightly bent shafts and rotors, and aggravated by ongoing wear and use. Since the real world is certainly not perfect, different types and aspects vibration will reveal a great deal about present conditions, as well provide insight into worrisome trends and even impending failures of bearing, shafts, and machine tools (Fig. 1):

- For bearings, the initial signs of wear typically create high-frequency noise that requires wide-bandwidth, low-noise sensors for early detection of initial bearing wear, which is often due to the impacts created by small fragments of metal.

- For shafts and motor frames, subtle changes in alignment and balance that can adversely affect motor performance demand low-noise, extremely stable accelerometers.

- Finally, the increased vibration levels of machine tools during high-speed operations, such as milling or cutting, can damage critical materials and reduce precision. Such cases require wide-bandwidth, low-noise sensors that can provide real-time data for feedback and enhanced machine control.

1. Frequency-domain analysis of a vibration-sensor output provides insight into mechanical conditions as well as accelerometer bandwidth and noise requirements.