Coiled Conductive-Thread Actuators Eerily Emulate Muscle Motion

The quest to replicate the flexibility, controllability, and dexterity of human muscles and associated limbs has inspired some truly “non-obvious” but highly workable actuator concepts. For example, actuators comprised of twisted threads that have been tightly wound around a mandrel can “pull-in” along their axis as the thread is heated—either by an tiny internal heater or by using conductive threads and self-heating—and then lengthens.

Called twisted-coil actuators (TCAs), these devices can be fabricated in various ways to provide types of motion that remarkably resemble a human muscle in action or even an octopus tentacle. And the amount of force they can develop is surprisingly high. However, existing TCA-actuated soft robots can only generate simple motion, since TCAs fabricated with conventional methods must be preloaded to generate a large contraction and thus can’t actuate soft robots properly.

Now, research, fabrications, and demonstrations at the Colorado State University by a team headed by graduate student Jiefeng Sun, working under Prof. Jianguo Zhao of the Mechanical Engineering Department, has led to an enhancement to TCA fabrication that can deliver 48% “free strokes” (contraction without preloading). By using a process that creates uniform gaps between neighboring coils, the TCA “muscle” has the ability to contract without being preloaded (Fig. 1).

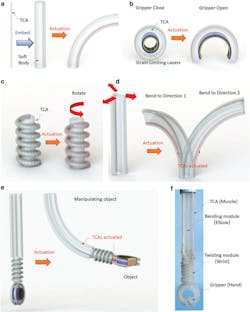

1. TCAs with free strokes can enable programmable motions for soft robots. (a) TCAs with free strokes can be directly embedded into a soft body to generate a large bending angle when actuated. (b–d) Versatile motions generated by arranging TCAs in soft bodies: (b) a 2D bending module (gripper) with TCA in a curved U shape; (c) a twisting module with a TCA in a helical shape; (d) a 3D bending module with three TCAs in parallel. (e) The schematic of a soft robotic arm with a 3D bending module, twisting module, 2D bending module. (f) A prototype of the soft robotic arm. (Source: Jiefeng Sun/Colorado State University)

Words cannot adequately convey the capabilities of these actuators, but the two-minute silent video below shows both their basic functionality as well as their use in robotic grippers (and they could also be used, in principle, for shape-shifting of airfoils and other surfaces).

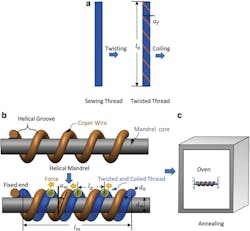

These actuators are made by continuously twisting conductive-thread fibers (a standard item available at local retail sewing and fabric stores), coiling it into a spring-like shape using a mandrel, and then heating them to a specific temperature to anneal and “set” the coiled shape (Fig. 2). These free-stroking actuators can be embedded into what’s known as a “soft robot” while achieving large magnitudes of motion.

2. Schematic showing the fabrication process of TCAs with free strokes. (a) Twist a sewing thread to generate a twisted thread. (b) Coil the twisted thread on a helical mandrel with a cylindrical mandrel core and helical grooves formed by a copper wire to generate coiled and twisted thread. (c) Anneal the coiled and twisted thread in an oven to generate the final TCA. (Source: Jiefeng Sun/Colorado State University)

By installing two or more such TCAs along a common flexible rod and controlling them independently, it’s possible to create bending and twisting motion in addition to simpler linear motion.

The TCA was powered by 10-V/1-A dc source, which is easily programmed to tailor the heating over the range rather than having to operate either full off or full on. As an added feature, the small change in thread resistance as it lengthens (and thus its diameter shrinks) can be measured, resulting in an inherent feedback sensor of the actuator status.

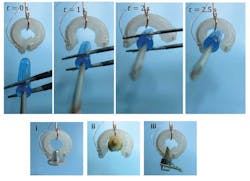

The researchers characterized how the various fabrication parameters influence the TCA’s stroke and force capability (Fig. 3), while also demonstrating that such TCAs can actuate centimeter-scale soft robots with programmable motions (gripping, twisting, and three-dimensional bending) (Fig. 4).

3. The TCAs can contract without preloading. (a) Microscopic photographs of the TCA in room temperature (top) and after being heated up (bottom). (b) Schematic of the TCA illustrating natural length ln, minimum length lmin, and the free stroke Sf. (c) The TCA pulls a weight against friction of 0.4N to generate a free stroke of 48%: (i) the TCA is in its natural length; (ii) the TCA is actuated to contract to its minimum length; (iii) the TCA automatically extends and recovers to its natural length after cooling down. (d) The TCA lifts a weight of 10 g against gravity to generate a loaded stroke of 55%, where l’min is the minimum length of the TCA when a weight is hung at the end and will be longer than lmin which is the minimum length of the TCA when no weight is hung (Source: Jiefeng Sun/Colorado State University)

4. An example gripping process of a screwdriver. Electricity is applied at t = 0 sec, the gripper opens wide enough at t = 2 sec. Finally, at t = 2.5 sec, the gripper closes and holds a screwdriver. Several objects that the gripper can grasp: (i) a metal screw, (ii) a small dc motor, and (iii) a printed circuit board. (Source: Jiefeng Sun/Colorado State University)

The work is described in full detail in their well-written and highly readable paper “Twisted-and-Coiled Actuators with Free Strokes Enable Soft Robots with Programmable Motions,” published in Soft Robotics. While that paper is behind a paywall, the lead researcher has fortunately posted an accessible copy here. In addition, previous thesis work by an earlier student also working under Prof. Zhao provides full modeling of the mechanical relationships among multiple factors such as thread diameter and winding, extension, pitch changes, forces generated, and resistance changes, and is posted as “Modeling of Twisted and Coiled Artificial Muscle for Actuation and Self-Sensing.”

About the Author

Bill Schweber

Contributing Editor

Bill Schweber is an electronics engineer who has written three textbooks on electronic communications systems, as well as hundreds of technical articles, opinion columns, and product features. In past roles, he worked as a technical website manager for multiple topic-specific sites for EE Times, as well as both the Executive Editor and Analog Editor at EDN.

At Analog Devices Inc., Bill was in marketing communications (public relations). As a result, he has been on both sides of the technical PR function, presenting company products, stories, and messages to the media and also as the recipient of these.

Prior to the MarCom role at Analog, Bill was associate editor of their respected technical journal and worked in their product marketing and applications engineering groups. Before those roles, he was at Instron Corp., doing hands-on analog- and power-circuit design and systems integration for materials-testing machine controls.

Bill has an MSEE (Univ. of Mass) and BSEE (Columbia Univ.), is a Registered Professional Engineer, and holds an Advanced Class amateur radio license. He has also planned, written, and presented online courses on a variety of engineering topics, including MOSFET basics, ADC selection, and driving LEDs.